What is the Triaxial Shear Test?

Triaxial testing is a type of shear test for solid materials performed while the specimen is under confining pressures on all sides. The confining pressures are generated in a fluid chamber to simulate stresses from surrounding soil materials. It then can give a clearer picture of the behavior of materials in place. This testing principle applies to rocks, powders, and construction materials, but this blog post will focus on the triaxial shear testing of soils.

What is the Purpose of the Triaxial Test?

The purpose of the various procedures is to measure the triaxial shear strengths of soil specimens subjected to different drainage conditions in the field. The results provide valuable information for the engineered design and construction of soil embankments, pavements, and structure foundations. Determining the mechanical behavior of soil materials through triaxial testing helps ensure that the soils supporting the structures are adequate for the proposed use – and its continued performance.

Triaxial shear testing for soils is not just one test. This blog post will discuss three different test methods, each one with variable requirements based on soil types and properties of individual specimens.

The Background Behind the Test

A Hungarian engineer named Theodore von Karman built one of the earliest triaxial test devices in 1912 for testing the behavior of brittle rocks for geophysical applications. Arthur Casagrande developed the first triaxial test for soils in 1930. Casagrande was a contemporary of and sometime assistant to Karl von Terzaghi at the Massachusetts Institute of Technology. During visits to German and Swedish soil mechanics research centers in 1929, he saw a need for an improved method of shear testing that accounted for the natural confining forces surrounding soil materials in place. Upon returning to MIT, he designed and built his first triaxial test apparatus for soils.

Casagrande's First Triaxial Device

Standard Test Methods for Soil Triaxial Shear

We will discuss three conventional test types of triaxial tests for cohesive or free-draining soil types; Unconsolidated Undrained (UU), Consolidated Undrained (CU), and Consolidated Drained (CD).

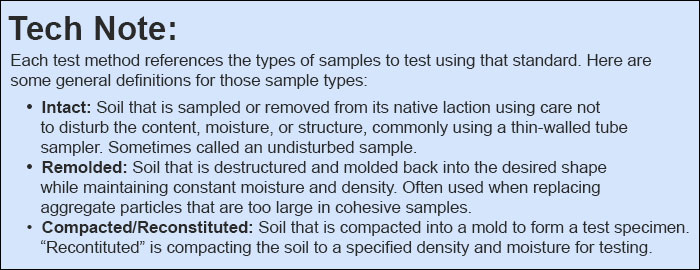

- ASTM D2850/AASHTO T 296 Unconsolidated Undrained (UU) Triaxial Compression Test on Cohesive Soils is also known as a “Q,” or quick-test. Specimens may be intact, compacted, or remolded soils. For this test, no drainage occurs during the consolidation or shear phases, and specimens may or may not be 100% saturated. Pore pressures are not typically measured. Loads are applied relatively quickly, and the sample theoretically does not consolidate. The Q test is intended for soils with very low permeability rates.

- ASTM D4767 Consolidated Undrained (CU) Triaxial Compression Test for Cohesive Soils is also known as the “R” test. Drainage is allowed during the consolidation phase, resulting in a volume change, but not permitted during axial loading. Axial load and deformation, along with pore-water pressure, are measured to determine total stresses and axial compression. Specimens must be 100% saturated for this test. Data collected from the testing of three samples at differing consolidation stresses allows a strength envelope to be defined.

- ASTM D7181 Consolidated Drained (CD) Triaxial Compression Test for Soils, also known as the “S,” or slow test. This test allows drainage in both the consolidation and shear phases, so there are no excess pore pressures at shear failure. The test is applicable for intact or reconstituted samples. Calculations for principal stresses and axial compression use measurements of the axial load and deformation, and volumetric changes. This method is suitable for free-draining soil types. If used for some cohesive samples, the test may take weeks to complete.

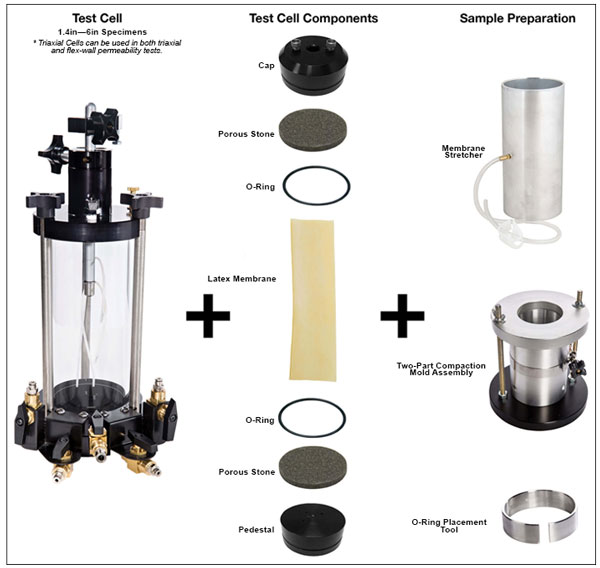

Triaxial Shear Test Apparatus

These are some significant components of the specialized equipment required for triaxial testing:

- Triaxial Cells are chambers in a variety of sizes where the prepared specimens are mounted. A pressurized fluid, usually water, in the cell creates confining pressure around the sample. Brass or stainless-steel fittings on the cell control filling and draining while a low-friction piston applies compressive force to the specimen during testing. Triaxial Test Cell Accessories are required and are available as individual items or a kit. Kits contain porous stones, latex membranes, cap and pedestal, and O-Rings corresponding in size to the test specimen.

- Load Frames apply axial loading forces at the correct strain rate to the specimen via the test cell. Load frames with10,000lbf or 20,000lbf (44.5 or 89kN) capacities and fitted with the proper triaxial components provide analog or digital measurement of pressures and deformation during testing.

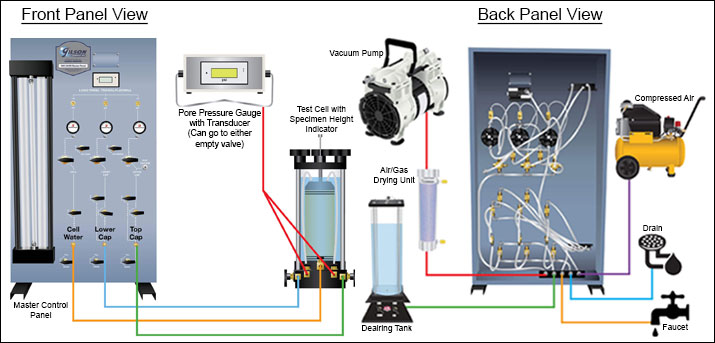

- Triaxial Control Panels equipped with measuring burettes, connections, and controls regulate and monitor fluid and air pressures, and the filling and draining of test cells. The Master Panel provides all necessary functions for a single test cell, and an Auxiliary Panel can be added for each new test cell to perform simultaneous testing.

- Pore Pressure Transducer is available to measure the pressure of fluids within the specimen during testing. This unit is available as a stand-alone instrument with an included digital readout.

- Triaxial Data Acquisition Software works together with Gilson digital triaxial load and deformation instruments to log, calculate, graph, and report axial load and deformation data of triaxial soil tests.

- The Vacuum Pump applies vacuum pressures for specimen saturation phases and deairing of water for triaxial and permeability testing. A laboratory Drierite Gas Drying Unit is a recommended accessory.

- Deairing Tank works with a vacuum source to remove entrapped air from water supplies for triaxial and permeability tests.

Typical Setup for Triaxial Testing

Sample Preparation

Soil samples, either undisturbed and extruded from thin-walled tube (Shelby tube) samplers, or remolded or compacted in the laboratory, are formed and trimmed to size using specialized sample preparation equipment. A latex membrane to control fluid migration, porous stones at each end, along with a cap and pedestal for mounting in the test cell, are fitted using a test cell kit and other tools and accessories.

Triaxial Shear Test Procedure

The assembled test cell containing the prepared specimen and water is mounted in the load frame. Air and water lines to the triaxial control panel are connected, and load and deformation measurement instruments are installed and zeroed. There are three phases for triaxial tests, and each step has variations unique to the particular test method. Successful testing depends on a thorough reading and understanding of the specific test method used.

- Saturation is the process of filling all voids in the soil specimen, as well as the porous stones and drain lines, with water without undue disturbance of the sample. The different test methods vary slightly on the steps required, but most use deaired water produced in a deaeration tank in conjunction with back pressure saturation. Backpressure, additional pressure applied to the pore-water of the specimen, compresses air in the sample and forces it into solution, thereby increasing saturation.

- Consolidation occurs under confining pressures applied to the fluid in the test cell. In the UU test, where drainage is not permitted, a totally saturated specimen cannot consolidate as a result of confining pressures. Partially saturated samples can consolidate and may have different strengths if tested at different confining pressures. For CU and CD specimens drained during consolidation, a volume change of the sample will occur. Drainage continues until consolidation reaches equilibrium, and the values determine the strain rate used during axial loading.

- Shear is the final phase of the test when the specimen is axially loaded. For the UU (or “quick”) test, the rate of loading is set between 0.3% and 1% per minute so that failure will occur within about 15 minutes. For CU and CD tests, strain rates must be calculated based on values from each consolidation phase and are much slower. Total test times may stretch into days or weeks for these methods.

Conclusion

Final calculations and data reporting for each test follow the requirements of the individual test methods. Clearly, triaxial testing is not one-size-fits-all. Each of the standards includes multiple variables based on specimen types and the protocol selected. If you have questions on your specific application, visit our triaxial testing equipment page for more information.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)