Quite a few ASTM and AASHTO soil tests performed in construction materials and geotechnical laboratories follow similar techniques using the same or similar equipment to set up samples for testing. With a little thought and planning, you can avoid the duplication of equipment and accessories needed to perform many sample preparation tasks. Specimens for soil mechanics tests often come from undisturbed fine-grained soil samples using thin-walled Shelby tubes or other hydraulic-push or drive-type samplers.

Soil Mechanics Tests

In this blog post, we’ll look at equipment and accessories to prepare samples for multiple soil mechanics tests:

- Triaxial Compression: ASTM D2850, D4767; AASHTO T 296, T 297

- Flexible-Wall Permeability: ASTM D5084

- Unconfined Compressive Strength: ASTM D2166; AASHTO T 208

- Soil Cement: ASTM D1633

- Direct/Residual Shear: ASTM D3080; AASHTO T 236

- One-Dimensional Consolidation: ASTM D2435; AASHTO T 216

For triaxial and flexible-wall permeability tests, sample preparation procedures are very similar, and some of the equipment is interchangeable. Unconfined compressive strength and soil cement strength tests use similar cylindrical specimens but are not enclosed in pressurized cells or mounted on porous stones for drainage. Consolidation and direct shear tests use shorter and more disc-like test specimens. Extrusion, visual classification, and preliminary sizing are similar to the other test methods, but require more specialized final preparations and mounting.

Extruding Shelby Tube Samples

Referring to Shelby tube soil samples as “undisturbed” may not be 100% correct, but it sends a message to handle these samples carefully. These special soil samples provide the most meaningful test results when they are properly taken and preserved.

On suitably outfitted soil sampling or drill rigs, soil samples are sometimes extruded from Shelby tubes in the field and transported to the laboratory following standard practices noted in ASTM D4220. In many cases, it is a better decision to keep the samples intact inside the tubes for later extraction under controlled conditions in the lab.

Photo Credit: www.hagertyenvironmental.com

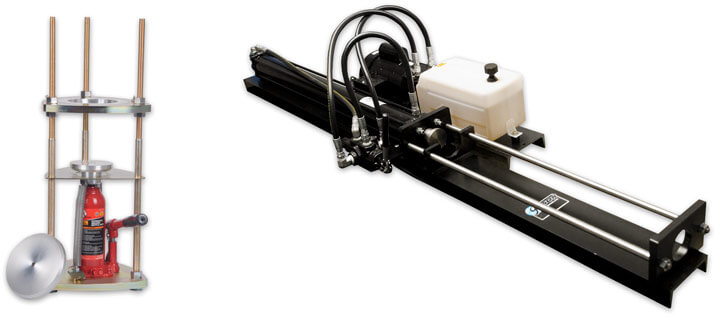

A single sample tube can provide two or more specimens for testing. Samples are typically extracted from the Shelby tube and preserved as soon as possible after sampling to avoid potential damage or issues with corrosion of the sample tube. ASTM D1587 requires a smooth, continuous extrusion action such as that provided by a hydraulic sample extruder. Soil sample ejectors can push soil samples out of shortened sections of Shelby tubes or other types of sampling tubes with suitable adaptors.

Samples intended for immediate testing may be cut to length using wire saws or straightedges with a beveled or sharpened edge and stored temporarily in airtight screw-top jars. For sensitive or fragile soil samples or longer-term storage, procedures in ASTM D1587 detail encasing samples in multiple layers of plastic wrap, foil, and microcrystalline wax.

Visual Soil Classification: Logging the Extruded Sample

During extrusion, part of the sample may be set aside for laboratory classification tests such as particle size and gradation, or Atterberg limits. Most labs will take the opportunity at this stage to visually classify characteristics of the recovered soils for grain size, appearance, bedding structure, and stiffness. The same basic tools used for soil field classifications apply to this process.

- Soil Pocket Penetrometer, Pocket Shear Vane Tester, and Geotester Pocket Penetrometer instruments all provide reliable estimates of unconfined strength and shear strengths of cohesive soils.

- Soil density volumeter makes rapid estimates of soil density using a small calibrated cylinder pushed into the sample.

- Munsell color book provides a universally accepted method for precisely describing colors, chromas, and hues of soils and other natural materials.

- Geotechnical classification charts establish boundary sizes for visual descriptions of soil particles. Sand-sized particles are attached to the cards, and size limits for gravel, cobbles, and boulders are noted in charts using the Unified Soils Classification System.

Sizing the Sample: Precision Trimming

Whether taken directly from a tube during extrusion or trimmed from a preserved sample of any shape, the dimensions of each specimen must be adjusted to the exact size specified for the particular test method.

An adjustable soil trimmer, or soil lathe, is used along with top platens and a wire saw or sharp trimming knife for diameter sizing. Top platens are selected based on the desired sample diameter. Soil trimmers perform either complete or preliminary sizing depending on the sample type and test method:

- Cylindrical samples, such as those used in triaxial shear, unconfined compression, and, flex-wall permeability testing, typically require a 2:1 height to diameter ratio. The diameter of the sample tube influences the final sample diameters, and most are in the 1.0 to 4.0in (25mm to 100mm) range. Typically, samples from a nominal 3.0in (76mm) Shelby tube produce 2.8in (71.1mm) diameter test specimens. The soil trimmer trims cylindrical specimens to precise diameters, ready for testing.

- Soil trimmers also perform preliminary sizing for round direct shear and consolidation test specimens, making final preparation easier. The final sizing of these samples for an exact fit to shear boxes and consolidometers uses specialized cutting rings.

Drainage & Flow Under Load

Triaxial, flex-wall permeability, direct shear, and consolidation tests are all influenced by hydraulic forces, water moving into and out of the soil matrix as loadings change. For accurate test results, the ends of these specimens must allow water to move freely.

- Porous stones are rigid metallic discs or squares that allow water to flow without restrictions and also provide a stable base on which the soil specimen rests during testing.

- Filter paper placed between the soil sample and porous stone reduces soil migration into the stone matrix and makes cleaning easier.

Protection from Fluid Pressures

Triaxial shear and flexible-wall permeability are very different soil tests but are both performed on similarly prepared samples in a fluid-pressurized cell. The test specimens are protected from fluid infiltration by a flexible membrane and share several preparation devices in common:

- Latex membranes are snugly fit over triaxial and flex-wall permeability samples during the sample preparation phase to seal them against the effects of fluid, typically water, under pressure during testing. Membranes are available for a variety of sample sizes in 0.012in or 0.025in thicknesses.

- Membrane stretchers use vacuum pressure to draw the latex membranes outward and allow easy placement.

- O-Rings seal the latex membrane and prevent leakage into the test specimen.

- O-Ring placing tools are available in different sizes and allow proper placement of the O-Rings without disturbing the specimen.

- Miter boxes allow trimming of the test specimens to a precise length with parallel ends, just as adjustable soil trimmers pare them to the correct diameter. These devices also use wire saws or trimming knives.

- Compaction mold assemblies are used with two-part compaction molds to prepare remolded samples of cohesive soil for testing. The devices include a base plate and fixtures to secure the mold during compaction.

- Two-part vacuum split molds prepare granular soil samples for testing. With this device, an applied vacuum draws a latex membrane against the sides while the soil is compacted inside.

- Caps and pedestals are positioned at the top and bottom of the specimens when mounted and fitted with drain ports and flow-through lines. Except for the 6.0in (152.4mm) diameter size, they are all compatible with either triaxial or flex-wall permeability samples.

- Test cell kits are available for specific sample diameters. Kits include a cap and pedestal, two porous stones, two latex membranes, and four O-Rings. The kits can be used interchangeably for either triaxial or flex-wall permeability samples, except for the 6.0in (152.4mm) diameter size.

- Permeability compaction hammer is designed to compact granular soils into permeameters following the ASTM D2434 standard (withdrawn) but is useful for other sample preparation applications as well. The device features an adjustable sliding hammer and can be used to prepare remolded samples for triaxial and flex-wall permeability tests.

We hope this blog post has given you a few ideas on choosing sample preparation equipment for the most common geotechnical laboratory tests.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)