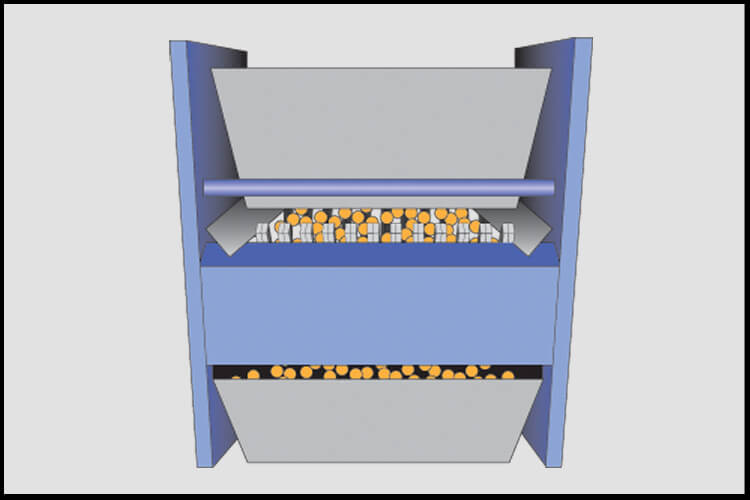

Riffle splitters were a popular tool in sampling and dividing, but had limitations, such as a narrow particle size range, uneven particle distribution, and poorly divided samples. To solve these issues, Gilson designed the Universal Splitter models with adjustable chute widths, a closed hopper to evenly distribute samples, and other features to produce more accurate and efficient sampling and dividing results.

- Log in

- Favorites List

-

Shopping Cart

You have no items in your shopping cart.

Gilson Insights

Have questions about your materials testing equipment? We have the answers to these questions and much more right here! Check back monthly for long-form blog posts, how-to guides and infographics. We’ll address industry insights, the operation and maintenance of specific equipment, and our product line recommendations, all designed to better serve you.

Bookmark this page, add it to your RSS reader, or subscribe to our newsletter, so you never miss a hot topic.

The term construction materials testing sounds like a catch-all term for analyzing everything from nails to doorknobs. However, for the civil engineering industry, it has come to mean the characterization of a handful of things by using specific test methods in a construction materials testing laboratory: concrete, aggregates, asphalt, and soils. This blog will take a high-altitude view of what construction materials are, the most important properties to test for, and the right equipment to get the job done.

Every stage of sampling, dividing, and testing granular material is affected by its flow properties. Understanding a particular material and the unique factors that impact its flowability increases the efficiency and accuracy of your laboratory testing and can even help control your budget. In this article, we discuss what equipment is best suited for your testing application.

In this blog post, we focus on the specialty large volume splitters. These sample dividers you may not see every day. They have unique features that could solve a problem for you when sample dividing coarse aggregates.

This blog post will focus on the core drilling method and the core sampling equipment. We discuss why and how core samples are taken from asphalt and concrete. Lastly, we touch on some of the different lab tests performed.

In part one of our special series on workplace safety, we take a look at how advances in materials testing equipment are minimizing potentially harmful exposure to dust in the lab.

Do you know when a spinning riffler or rotary sample divider should be your go-to sample divider for the most accurate representative samples?

Is your lab or worksite equipment-ready for compliance with OSHA’s final rule for the construction industry on protecting workers from exposure to silica dust?

When it comes to choosing a splitter, accuracy means everything. We’ve outlined some helpful guidelines that will walk you through the splitter selection process. We’ll cover everything from material type to high-performance features with the goal of helping you select your ideal splitter.

- 2026

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015