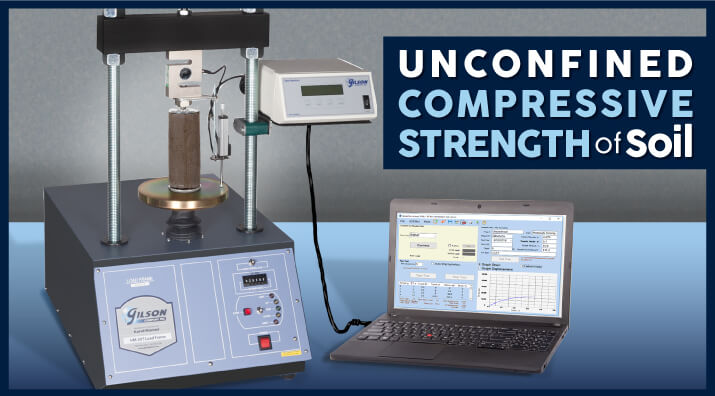

a rapid, uncomplicated procedure makes unconfined compression tests cost-effective when fundamental strength values are adequate for design. |

Unconfined compressive strength is a standard geotechnical test performed on cohesive soil samples in construction materials testing laboratories. Intact, remolded, or reconstituted cylindrical soil specimens are axially loaded to failure on a laboratory load frame as stress forces vs. strain (deformation) values are recorded. Straightforward sample preparation and a rapid, uncomplicated procedure make unconfined compression tests cost-effective when fundamental strength values are adequate for design. Shear strength is one-half of the compressive stress at failure. Unconfined compression is not a substitute for triaxial shear methods that replicate in-situ lateral confining pressures more accurately.

Soil Types

Unconfined compression (UC) is a valid strength test for most cohesive soil types, but there are some exceptions:

- Soils that expel or bleed water during testing and do not retain strength after loading.

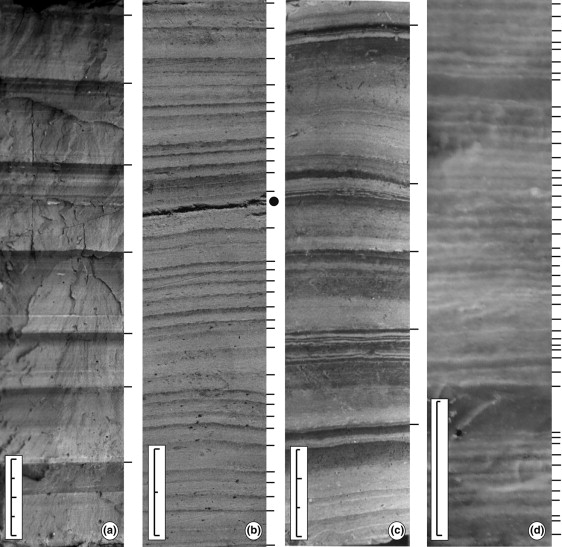

- Soils that are dry/crumbly, fissured, or have a varved (alternating thin layers of clay and silt or sand) structure.

Varved Soils

Photo Credit: sciencedirect.com

- Very soft clays or clays that exhibit slickensides (smoothly polished surfaces resulting from friction along two sides of a plane).

For these soil types, ASTM D2850, unconsolidated, undrained triaxial compression, is a more suitable test method for strength determination and will generally result in higher shear strength.

Sample Types

ASTM D2166/AASHTO T 208 describes the sample types acceptable for using the unconfined compressive strength method.

Shelby Tube Sample

- Intact samples in thin-walled "Shelby tubes" are acquired using methods described in ASTM D1587 intended to preserve the structure, density, and moisture content of the original, or in-situ, soil formation. “Undisturbed” is a term previously used to describe this process, but "intact" is considered a more accurate term.

- Remolded soil samples have been broken down or “destructured,” then formed back into a cylindrical shape that maintains similar moisture and density and meets the dimensional requirements for testing. Remolded specimens use the material from failed intact samples reformed into new specimens to determine the effects of remolding on soil strength. This comparison allows the calculation of the sensitivity ratio.

- Reconstituted soils are modified in the laboratory to meet prescribed characteristics. The original soil may be changed by blending or by adjusting its gradation or plasticity. It may be augmented with lime, cement, or other additives.

ASTM D653 is a reference for standard definitions related to soil and rock and contains complete explanations of these terms.

UCS Laboratory Equipment

Selecting the right laboratory equipment for compressive strength testing of soil ensures accurate, reliable, and cost-effective test results.

- Sample Preparation Equipment for the unconfined compression test is not elaborate, but selecting the right tools makes the process less complicated.

- A reliable Sample Extruder removes even stubborn samples from a Shelby tube while maintaining their integrity for testing. A hydraulic extruder with a stroke equal to the length of the sample tube pushes the intact sample out in one continuous motion with minimal disturbance to the soil.

- Adjustable soil trimmers allow the exact diameter sizing of soil specimens for testing. An adjustable soil trimmer used with a wire saw functions as a vertical lathe to shave material from an oversized sample to achieve the desired diameter.

- Wire saws secure a thin metal wire in tension to trim cohesive soil specimens to the desired length or diameter.

- Two-Part Miter Boxes allow the cutting of specimens to exact length with square ends for efficient transfer of loads. The miter boxes are supplied in popular diameters and firmly support the entire length of the specimen while trimming to length and squaring the ends.

- Two-Part Compaction Mold Assemblies efficiently form remolded or reconstituted soil samples ready for testing. Two-part molds are available separately or as assemblies, complete with a collar and base plate.

- Load frames are an essential piece of laboratory equipment when performing UC testing. Gilson recommends using motor-driven laboratory load frames with precisely controlled strain rates paired with analog or digital component sets to measure force and axial deformation. Manually operated load frames require watching a timing device while turning the loading handle at a pace to match the required strain rate, all while writing down the applied loads and strain readings at the correct elapsed time intervals. Motorized load frames simplify the loading process by advancing the platen at the correct rate with no human input. Outfitting the load frame with electronic load and deformation instruments and outputting data to computer software further reduces the possibility of human error.

- Load and Deformation Measurement can be performed with the simplest of analog devices or with sophisticated electronic instruments capable of acquiring and uploading data to computers. Gilson's analog or digital component sets completely outfit any manufacturer’s load frame for testing to ASTM/AASHTO standards. Individual components are also available separately.

- Analog Component Sets feature a precision-machined load ring with a dial gauge to measure loading forces. A separate mechanical dial gauge with a mounting bracket indicates sample deformation.

- Digital Component Sets consist of an S-type load cell, a linear variable displacement transducer (LVDT), a two-channel data readout, and a mounting bracket. This configuration enables data transfer to a computer spreadsheet or for importing into analysis and reporting software.

- Data Acquisition Software is used with digital components and shows real-time stress vs. strain values graph. Data is automatically collected, calculated, and reported, minimizing operator error and increasing efficiency.

Soil Sample Preparation

Most intact cylindrical specimens for unconfined compression are prepared from Shelby tube samples, obtained, and preserved following methods in ASTM D1587. Sample preparation is straightforward, using a hydraulic extruder to reduce disturbance to the soil.

Extrude the sample in a smooth, continuous motion in the same direction that the soil entered the tube. Tube samples of intact soil need only be trimmed to length and have the ends squared in a miter box to be ready for testing. Field-excavated intact block or cylindrical samples acquired following ASTM D7015 practices need more extensive preparation using a soil trimmer, and wire saw to produce a specimen ready for testing. Trimmings from this process can be used for soil moisture and specific gravity determinations. Avoiding moisture loss and sample disturbance is key to producing valid test results throughout the sample preparation process.

For remolded unconfined compression specimens, soil from the previously tested intact specimen or unused sample material is recovered and manually kneaded in a latex membrane before compacting into a two-part mold for forming. Density and moisture content should be close to the original values. Remolded specimens help predict soil characteristics when compacted during construction operations such as embankment or structural fills.

Tests of the same soil in intact vs. remolded conditions can also be used to determine the sensitivity of cohesive materials. The sensitivity value is the measure of the loss of shear strength of the remolded soil. In extreme cases, soils with very high sensitivity may become viscous or “quick” when remolded and would be unsuitable for engineered fills.

The test method specifies a length-to-diameter ratio (L:D) between 2:1 and 2.5:1. So, the length of a 2.8in (71.1mm) diameter sample should be between 5.6in and 7in (144.2mm to 177.8mm). Samples under compression generate friction between the machine platens and the soil, restraining movement at the sample ends. Samples that are too short have an exaggerated reaction to this restraint and may exhibit a higher apparent compressive strength. On the other hand, samples that are too long may buckle in the middle rather than fail in true axial compression. Two-part miter boxes in popular sample diameters have required lengths.

Unconfined Compression Test Procedure

The test method recommends selecting a rate of strain between 0.5% and 2.0% that will load the sample to failure in no more than approximately 15 minutes. Doing so entails some assumptions, simple calculations, and guesswork. Soft soils deform more before failure and should be tested at a higher rate. Stiff soils exhibit less deformation and should be tested at a lower rate. A 1% strain rate for a 5.60in (142.2mm) long sample requires advancing the platen of the load frame at 0.056in (1.42mm) per minute. For a softer sample of the same size, a 2% strain rate would need a platen speed of 0.112in (2.84mm) per minute.

Center the prepared test specimen on the lower platen of the load frame and adjust the upper platen so that it just contacts the specimen. Adjust all the instruments measuring load, time, and deformation to their proper positions, ready to take readings. Start applying the load at the calculated strain rate. The time intervals to record load and deformation values should be sufficient to produce a well-defined stress-strain curve of at least 10 to 15 points. The test is complete when load values decrease or strain values reach 15%. Record the slope angle of the failure and condition of the sample using a hand-drawn sketch or photograph. If trimmings were not collected earlier, use the failed sample for a moisture content determination.

Reporting Test Results

Results of the soil unconfined compression test are calculated using axial strain, average cross-sectional area, and compressive stress values.

- Axial strain, ε1:

ΔL = Length change of specimen

Lo = Initial specimen length

- Average cross-sectional area, A:

A0 = Initial cross-sectional area

ε1 = Axial strain

- Compressive stress, σc:

P = Applied load

A = Average cross-sectional area

- The maximum compressive stress, or the compressive stress at 15% strain, whichever occurs first, is reported as the unconfined compressive strength, qu.

- Sensitivity, ST, can be calculated using results from intact and remolded tests:

References:

- Unconfined Compressive Strength of Soils, ASTM D2166, AASHTO T 208

- Thin-walled Tube Sampling of Soils, ASTM D1587

- Unconsolidated-Undrained Triaxial Shear Test of Soils ASTM D2850

- Obtaining Intact Block Soil Samples ASTM D7015

We hope this blog has helped you understand the techniques and equipment needed to perform the soil unconfined compression test. Visit our unconfined compressive strength test equipment page for a complete list.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)