Concrete compressive strength has steadily evolved over the last century. Read about how Rigid Frame Concrete Compression Machines can withstand today's high-performance concrete mix designs.

Concrete compressive strength has steadily evolved over the last century. Read about how Rigid Frame Concrete Compression Machines can withstand today's high-performance concrete mix designs.

- Log in

- Favorites List

-

Shopping Cart

You have no items in your shopping cart.

Blog posts tagged with 'Compressive Strength'

Have questions about your materials testing equipment? We have the answers to these questions and much more right here! Check back monthly for long-form blog posts, how-to guides and infographics. We’ll address industry insights, the operation and maintenance of specific equipment, and our product line recommendations, all designed to better serve you.

Bookmark this page, add it to your RSS reader, or subscribe to our newsletter, so you never miss a hot topic.

Concrete compressive strength has steadily evolved over the last century. Read about how Rigid Frame Concrete Compression Machines can withstand today's high-performance concrete mix designs.

Concrete compressive strength has steadily evolved over the last century. Read about how Rigid Frame Concrete Compression Machines can withstand today's high-performance concrete mix designs.

Modulus of Elasticity (MOE) and Poisson's Ratio are concrete compressive strength tests that can be performed using an Automatic Concrete Compression Machine. Learn how these tests are performed in our latest blog.

Gilson Guardian makes it possible to track concrete specimens from curing through completion. Learn how one program can enhance your lab's concrete testing programs.

The right Concrete Compression Testing Machine will shape the overall success of your concrete testing. In this guide, we explain the different machines available and how to determine the best option for your lab.

Laboratory load frames perform multiple test methods on a variety of soil, asphalt, and cement materials simply by changing prescribed components used for load and distance measurements. This blog post introduces Gilson’s innovative Servo Control Load Frames and explores important considerations for selection of a suitable load frame and testing components for your applications.

Increase the overall performance of your basic or manual concrete compression testing machine by upgrading to automatic operation with an Automatic Controller Retrofit. Learn more about the benefits of automatic operation and see how easy it is to install a Retrofit to your existing compression machine.

The two most popular types of end treatment for cylindrical concrete specimens are sulfur mortar capping and neoprene compression pads. Both have their advantages. Neoprene pads are convenient and reusable many times over. Sulfur mortar is economical when testing large numbers of cylinders, and is often the preferred end treatment for cylinders because of its long history of use. Reliable strength results and consistent display of fracture patterns are predictable and well understood. In this article, we go over the equipment and techniques used for sulfur mortar capping.

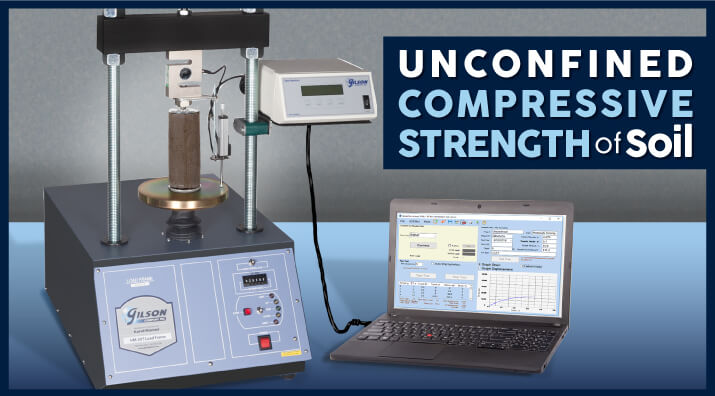

Unconfined compressive strength is a standard geotechnical test performed on cohesive soil samples in construction materials testing laboratories. Straightforward sample preparation and a rapid, uncomplicated procedure makes unconfined compression tests cost-effective when fundamental strength values are adequate for design.

Testing the properties of hardened concrete is central to evaluating a structure, whether it is decades old or still under construction. In-place testing of concrete is a significant part of assessing an existing structure's safety and physical condition for routine maintenance before modifications. This blog post will discuss in-place and nondestructive methods and equipment to measure concrete strength.

In this month's blog post we will focus on standard-cure cylinders made for compressive strength acceptance testing. Including the importance of cylinder testing, a quick guide on the procedure, and the equipment needed in the field and lab.

- 1

- 2

- 2026

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015