Advancement in Information Management for Concrete Testing Programs

Gilson Guardian Benefits

There is nothing complex or difficult about running a successful concrete testing program. Well-trained technicians perform fresh concrete tests on-site following exacting standardized methods and project specifications. The strength test specimens are retrieved from the job site for timely and intact delivery to the testing lab. The cylinders or beams are tested on the correct date following the proper methods, and verified test results are quickly distributed to all the right parties.

If you laughed out loud at that opening paragraph, keep reading, this blog is for you! Fortunately, testing really does go as planned most of the time, but in an operation with so many moving parts, the list of things that could go wrong is nearly endless.

Challenges in Concrete Testing

Realistically, concrete testing for a construction or paving project is three separate but closely linked undertakings.

- Field: Concrete batches delivered to the job site are documented, acceptance tests on the fresh concrete are performed, and strength samples are molded for later testing.

- Laboratory: Strength test samples are delivered to the lab, de-molded, labeled, and logged in for final curing. The concrete cylinder or beam samples are tested for strength at the designated ages following specified test methods.

- Reporting: Field documentation and laboratory testing information are merged and reported to owners, architects, engineers, and contractors. The testing lab becomes the de facto archive of the project's concrete test results and statistics.

There are plenty of opportunities for the introduction of human error. Field technicians might pencil in incorrect information from batch tickets. Someone sent to pick up strength samples may not find the curing box. Lab techs could calculate the wrong test date, or maybe a flexural beam is tested using third-point loading instead of the specified center-point method. And how about the contractor who wasn't copied on that failed strength test report for concrete on the floor below?

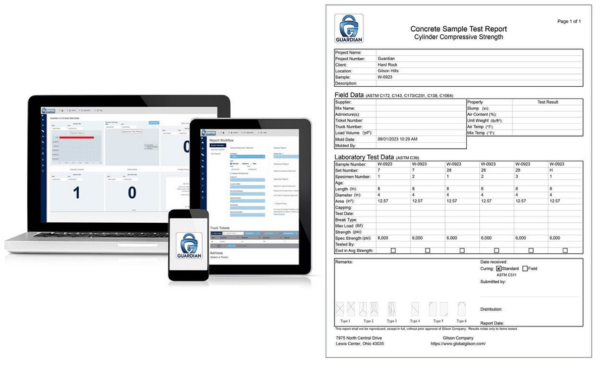

Gilson Guardian: Sharing Information Securely

Gilson Guardian is a secure cloud-based platform for the information management and sharing of concrete inspection and testing data. Guardian is a three-part system including a mobile app for recording data in the field, software that tracks sample status and integrates with the human-machine interface (HMI) of Gilson Automatic Compression Machines, and a cloud-sharing platform for access and reporting.

Seamless tracking of each concrete batch and the entire lifecycle of each strength specimen tested is documented, uploaded, and reported in real-time. Thanks to its cloud-based architecture, Guardian can be accessed by users with registered credentials from any location with an internet connection.

Guardian software integrates with Gilson Automatic Concrete Compression Machine controllers and Automatic Controller Retrofits to fully leverage their capabilities. When used with optional labeling and scanning apparatus, concrete specimen information merges with strength data to generate complete testing reports virtually free from human error.

Project stakeholders never again need to be in the dark about concrete quality or placement conditions, the status of strength test results, or the security of their project information. Human error is minimized, and cloud-based, verified data is instantly available to anyone authorized to see it.

Source: https://www.shutterstock.com/image-photo/construction-worker-hands-using-smartphone-on-1901706478

Gilson Guardian's Mobile App for Field Operations

The Guardian mobile app is where the data stream begins for all concrete placement records and each test specimen. The mobile app is a free download for iOS or Android Smartphone users and is included when the cloud-based software is purchased.

Project ID and location, concrete supplier, mix design, sampling requirements, and other information can be input from a smartphone or pre-entered into the project folder to save valuable time on-site and serve as a guide to the field technician. All mobile data can be input with or without internet connectivity. As soon as a service connection is established, the app automatically syncs to the cloud and updates the information.

Complete batch and placement information for every load is entered and managed, and test results for fresh concrete properties are logged in the mobile app. All the information recorded on-site is uploaded to the cloud and appears in the web application in real-time. When strength specimens are cast, their assigned set number and other data remain linked with those specimens throughout the collection, curing, lab testing, and reporting phases.

A long list of customizable form fields in the mobile app can be individually toggled on or off to standardize data collection across multiple projects or to customize documentation for an individual project. Concrete properties, mix designs, fresh concrete test results, and placement observations are recorded for inclusion in reports accessed by approved associates. A GPS plotting function allows users to pin a map with the exact geolocation of the specimens on the site for later pickup.

Source: https://www.concreteconstruction.net/how-to/construction/strength-testing-of-hardened-concrete_o

Identification, Retrieval, and Laboratory Curing of Concrete Test Specimens

The mobile app's time, date, and location information flags each set of concrete specimens for scheduled retrieval by the testing lab after initial field curing. Geolocation data details the project location and the exact on-site placement of samples for efficient collection and transport.

Upon arrival at the testing lab, test sets are logged into the web-based app, and each specimen is automatically assigned a test date before being de-molded and prepared for curing.

When the optional QR Code Scanner and Label Printer Kit is used, labels with QR codes are printed for direct attachment to individual concrete specimens. The durable plasticized labels stand up to the harsh conditions of curing tanks or moist rooms, ensuring accurate specimen identification and reliable entry of test results into the Guardian database.

Automated Concrete Strength Testing

The status of test samples for each project is tracked by the Guardian application, including specimen ID and type, test type, test date, and type of end preparation required. A daily check of the Guardian dashboard page indicates specimens due for testing and allows checking for specimens that require extra time for end preparation, such as sulfur mortar capping, grinding, or saw-cutting.

The Gilson Guardian System works with the HMI (Human-Machine Interface) controller of our Automatic Concrete Compression Machines to ensure reliable tracking, testing, and reporting of concrete strengths. Guardian software also integrates with Gilson's Automatic Controller Retrofit systems when upgrading older manual compression machines.

When the Gilson Guardian system is used with QR scanning, specimen labels are scanned to upload specimen ID and testing requirements to the HMI controller. The controller carries out load application and rates, break detection, and data logging for each specimen, strictly following relevant ASTM or AASHTO specifications. Human input is minimized, ensuring accurate reporting. Customized reports are generated for in-house review and then uploaded to the cloud to be shared with stakeholders.

- When the QR label of each test specimen is scanned, all relevant data is preloaded directly into the compression machine's HMI. The possibility of input errors is at an absolute minimum.

- The HMI validates parameters of the ASTM or other standard test method for that particular specimen, and an automated strength test cycle is initiated with the push of a button.

- The HMI dynamically controls preloading and final load rates based on specimen age, mix design, and expected strength. Automatic break detection eliminates the guesswork and ensures an accurate and reliable strength test.

Concrete Test Review and Reporting

When the concrete strength specimens' testing cycle is complete, results are automatically posted to in-house platforms for reviews, approvals, and digital sign-off. Programmable smart checks flag deviations from expected specimen characteristics or strength requirements.

The entire project design and construction team now has instant and secure access to read and download accurate and reliable strength test reports that have been reviewed and finalized. No more waiting on extra steps for data entry or postal delays.

Cost-Effective Integration

The expense and time required to install and customize typical enterprise cloud-sharing applications can be considerable. Guardian software is designed and optimized solely for concrete applications by industry professionals experienced in concrete testing. Support for the Guardian system is administered directly by Gilson.

Gilson levels the playing field with flexible software that is ready for use upon installation. Guardian is the right size to grow with organizations with limited testing programs and large enough for testing labs with dozens of active projects.

Four subscription tiers are based on an expected number of monthly tests and are billed monthly or annually in installments for easy budgeting. If the subscribed number of tests is exceeded, users can choose to pay a nominal fee for the additional tests or upgrade to a higher tier.

- Essential Plan: This tier is billed at a base subscription rate plus a $0.25 charge per test. This is a cost-effective plan for users performing a limited number of tests per month for a few projects.

- Professional Plan: This plan covers up to 500 tests per month.

- Professional Plus Plan: For busier labs, the Professional Plus accommodates 2,500 tests per month.

- Premium Plan: For regional labs with multiple offices and a substantial testing volume, the Premium Plan covers up to 5,000 tests per month.

We hope this introduction to the Gilson Guardian cloud-sharing application has provided some insight into this important advancement in information management for concrete testing programs.

Additional Resources

The Automation Revolution: Concrete Compression Machines

Concrete Cylinder Testing - From the Field to the Lab

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)