Classification of Soils in Civil Engineering

The disciplines of agriculture, soil science, geology, and civil or geotechnical engineering all have interests in evaluating soil properties. The focus for each field is slightly different, and all have evolved in different directions.

Geotechnical engineers are most interested in how soils will respond to physical forces imposed by structures, roads, and bridges, or artificial earthworks like dams and levees. Their systems for classification of soils permit a universal design "language" for foundation and pavement designs.

Why is Soil Important to Civil Engineers?

The first steps of design for nearly all engineered construction projects require exploratory sampling, testing, and analysis of soil and rock materials. This sampling, classification, and testing program provides answers for geotechnical engineers to determine the soils' suitability for the proposed use.

Soils classification begins by identifying particle size and composition, density, and moisture characteristics that influence fundamental engineering properties like strength, permeability, and consolidation.

How are Soil Samples Taken?

Traditional soils investigations involve truck or track-mounted rotary drill rigs using split-spoon samplers for ASTM D1586 standard penetration testing (SPT) or Shelby tube samplers to extract ASTM D1587 undisturbed samples. Newer direct-push equipment described in ASTM D6282 uses hydraulic pressure to advance the hole depth and obtain samples of the soil. Manually operated soil sampling equipment is used for smaller projects and in remote locations. Of course, the old-school shovel and bag method is still an option if the samples are not used in critical lab tests.

What is Soil Classification?

This blog explores the two primary forms of soil classification for geotechnical purposes. Visual and laboratory classifications of soils are two distinct procedures that are part of a complete soils investigation.

- Visual classification ideally takes place in the field as the samples are freshly recovered and examined within the context of their natural environment. Each sample is visually scrutinized, manipulated in the hands, even sniffed, or tasted to help identify basic features. Visual classification records descriptions of soil properties in sampling logs and helps create a profile of the soil formations. The descriptions may also include estimates of which ASTM or AASHTO classes the samples would fall into.

As discussed in a previous Gilson blog How Simple Soils Inspection Equipment Promotes Trench Safety, the visual classification and evaluation of soils is front and center in practicing trench safety and worker protection required by OSHA Publication 29 CFR 1926, Subpart P.

- Laboratory Classification subjects selected representative samples to standard laboratory soil tests. Results are used for engineering designs of foundations, pavements, or embankments and index samples into specific ASTM or AASHTO soil groups.

How to Visually Classify Soils

Descriptions of color, particle size and shape, stiffness, density, moisture, and other sample properties are logged and used to create the site's soil profiles. Field classifications may be used to assign the samples to group indexes of ASTM or AASHTO classification systems. Not every soil sample taken in the field is tested in the laboratory. Visual classification is an efficient way of ensuring that each sample is examined to document basic features.

The Modified Burmister System was developed as a quick and accurate field method for complete, structured soil sample descriptions. In 1950, Columbia University Professor Donald Burmister recognized the need for a comprehensive approach that was simple and easy to use. His method uses words like "some," "little," or "trace" to represent the proportions of particle sizes, and other standardized terminology describes texture, structure, and color. Consistency, stiffness, and moisture are defined by manual manipulation of the sample. Blow counts from the Standard Penetration Test (SPT) may be used to depict soil density. ASTM D2488 is another standard practice for visually identifying soils and is based on the Unified Classification System (USCS).

Geotechnical Gauge

Geotechnical Reference Charts and Other Tools

- Soil classification kits contain the essential equipment for the visual classification of soils in the field.

- Soil Penetrometers and shear vanes provide quick estimates of shear strength and characterize soil stiffness. An adapter foot for the Pocket Penetrometer allows the testing of soft soils.

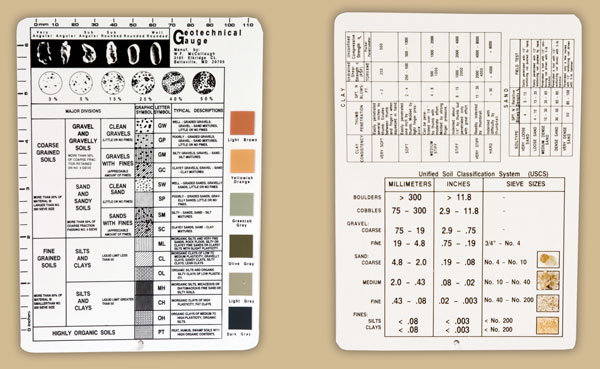

- Geotechnical Classification Charts are good "cheat sheets" to aid in assessing soil grain sizes, descriptions, and classifications

- Munsell soil color book is a book of standardized soil colors used to describe soils or other natural materials.

Consistently accurate visual classification of soil samples is a learned skill and improves with practice. Comparing field logs with final laboratory test results on particular samples is the best way to develop accuracy and consistency.

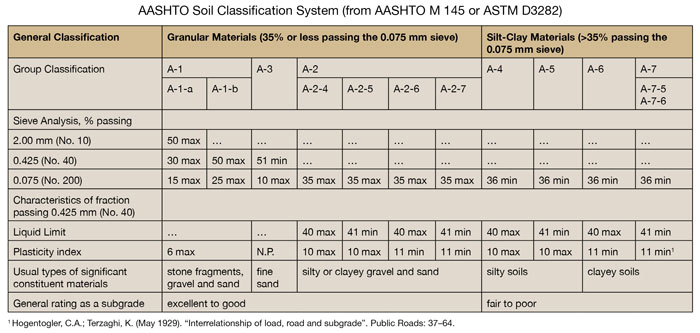

AASHTO Grain Size Classification Table

Photo Credit: www.aashtoresource.org

How to Identify Soil Types in the Laboratory

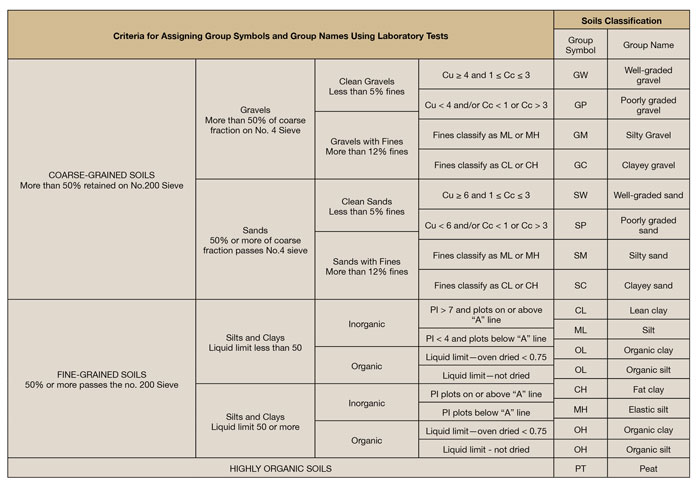

Laboratory tests to classify soil types' characteristics are mostly limited to particle size, Atterberg limits (liquid and plastic limits), and natural moisture contents, properties that have a direct impact on soil bearing capacity, stability, and drainage. Results from these basic tests place the soils into their respective groups or classes.

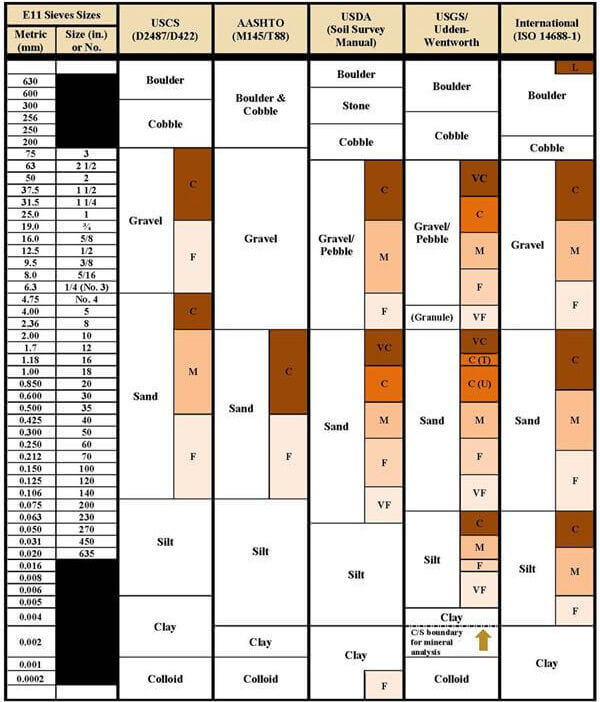

- Particle size distribution for soils with coarse material requires a selection of test sieves meeting ASTM E11 or ISO 3310-1 requirements. For optimum accuracy and efficiency, a suitable sieve shaker should be used as well. Wet sieving, or washing, to eliminate fines passing the #200 (75µm) sieve is often required for accurate sieving.

- Particle size distribution for soils with significant silt and clay contents will involve hydrometer testing.

- Atterberg limits test equipment establishes the liquid limit, plastic limit, and plasticity index (PI) of fine-grained soils.

Other geotechnical and soil mechanics analyses measure specific aspects of strength, consolidation, or permeability, but particle size and Atterberg limits tests are essential for classification.

Common Laboratory Tests to Identify Soil Types:

| Name of Test Standard | ASTM Standard | AASHTO Standard |

|---|---|---|

| Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis | D6913 | — |

| Particle-Size Distribution of Fine-Grained Soils by Hydrometer | D7928 | T 88 |

| Amount of Material Finer than 75µm (No. 200) Sieve in Soils by Washing | D1140 | T 11 |

| (Atterberg) Liquid Limit, Plastic Limit, and Plasticity Index of Soils | D4318 | T 89 and T 90 |

| Laboratory Determination of Moisture Content of Soils | D2216 | T 265 |

Soil Classification Systems

The ASTM Unified Soil Classification System (USCS) and the AASHTO soil classification system are widely used for engineering soil classifications. Each has specific published standards, and there are numerous variations created by end-users for particular applications.

- ASTM Unified Soil Classification System (USCS) is widely practiced and considered a common language when discussing soil classification for engineering purposes. The system is a standard practice published in ASTM D2487. The "Airfield Classification System" was developed in the early 1940s by Arthur Casagrande in response to the need for rapid construction of military installations and is based on soil particle size and plasticity values. Soil types are divided into the major classes of coarse-grained, fine-grained, organic soils, and peat, each with subgroups and unique characteristics. The system does not describe moisture or density characteristics of freshly sampled soil.

- Classification of soils and soil-aggregate mixtures for highway construction purposes is a system developed by Karl Terzaghi in 1929. AASHTO M 145 and ASTM D3282 are similar practices based on this method. Soil types are divided into eight classes using a calculated group index (GI). The GI for a soil type is derived from the percent passing the No. 200 (75µm) test sieve, the liquid limit, and the plasticity index.

We hope this blog post has helped your understanding of the different soil classification types for civil and geotechnical engineering applications.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)