California Bearing Ratio of Soil

The California Bearing Ratio or CBR test is performed in construction materials laboratories to evaluate the strength of soil subgrades and base course materials. Those who design and engineer highways, airport runways and taxiways, parking lots, and other pavements rely on CBR test values when selecting pavement and base thicknesses.

CBR Test Methods

The laboratory test method in ASTM D1883 and AASHTO T 193 for the CBR test is a simple empirical method, comparing resistance to penetration of the test specimen to that of a “standard” sample of well-graded crushed stone material using a standard-sized piston. The test does not characterize any soil properties aside from resistance to penetration. The Florida Department of Transportation developed a modified version of this method as the FM 5-515 Limerock Bearing Ratio (LBR) Test.

CBR testing can also be performed in-place on soil subgrades with an apparatus using the same size penetration piston or with the dynamic cone penetrometer (DCP). ASTM D4429 is often used as an exploratory test to determine in-place conditions of soils or bases or to confirm laboratory test results. This blog post will discuss the laboratory and field CBR methods, along with the DCP.

Why the CBR Test is Important

In the early 1900s, economic development drove the demand for more miles of better-quality roads, which in turn resulted in increased road traffic. In 1928 and 1929, engineers at the California Division of Highways (now Caltrans) developed the CBR test to ensure pavements could be economically constructed and still carry the anticipated axle loads. They established the penetration resistance of ideal crushed-rock base material as a standard reference to compare against all other soil and base course materials. California officially adopted the CBR test in 1935, and it is now a standard method in ASTM, AASHTO, U.S. Army Corps of Engineers (USACE), British Standards, and others. CBR values are recognized as integral to pavement and runway design by state Departments of Transportation, the Federal Highway Administration (FHWA), and Federal Aviation Administration (FAA). Extensive use of the California Bearing Ratio over a long period and information gained from field correlations have established its reliability for pavement design.

CBR Test Procedure

CBR Laboratory Test Preparation

Sample preparation takes up most of the time required for testing CBR samples in the geotechnical laboratory. Materials proposed for the project are sampled and processed in the laboratory into a series of test specimens.

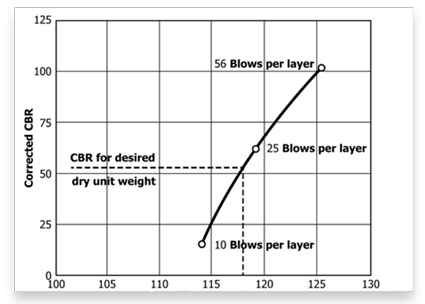

Preparation takes place using the same or similar steps found in method C of ASTM D698 or D1557 (AASHTO T 99 and T 180) moisture/density relationship (Proctor) tests. The specifier of the CBR test may request changes to the dry density of the specimens. Changing the required number of blow counts will adjust the dry density. Spacer discs, surcharge weights, and other apparatus to measure expansion are also necessary.

The test mostly applies to cohesive materials with maximum particle sizes less than 19 mm (0.75 in) but can also be used to evaluate the strength of granular soils and aggregates. For most methods, three to five samples are prepared and soaked for a period before the penetration test. The prepared test specimens are positioned in a load frame and subjected to regulated penetration loads from a piston with a surface area of 3in² (1,935mm²). Loads are recorded at specified penetration intervals and plotted graphically.

Several variations in sample preparation test methods are possible in the CBR test. Test methods can include a single sample tested at optimum water content (as determined by ASTM D698 or D1557), a series of three test specimens at optimum water content tested at different maximum dry unit weights, or the testing of each sample used in the development of a compaction curve. The two latter methods may also require compaction of several samples with different blow counts to adjust the final density of the sample materials. Selected test protocol should be clearly understood by all stakeholders, and especially the testing lab before preparation begins.

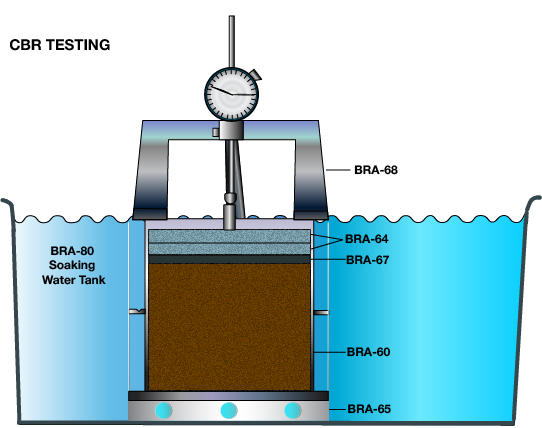

Soaked CBR Test Specimens

Soaking accounts for adverse moisture conditions from potential rainfall or flooding, and most CBR tests use this procedure. In addition to the compaction process, preparation usually involves soaking each specimen in water for 96 hours before the penetration test.

During the soaking period, a surcharge load of 10lbf (4.54kg) or more must be placed on the sample using surcharge weights to simulate the weight of the pavement and other loads specified. The soil swell resulting from soaking must be measured using expansion measuring apparatus and swell plates placed on the sample before penetration testing. It takes a significant amount of time to prepare multiple compacted specimens for a single test. Complete CBR testing sets containing multiple CBR molds and components are available to maximize testing productivity and efficiency.

Note: Unsoaked tests are not unusual in areas where rainfall amounts and the local water table are both low.

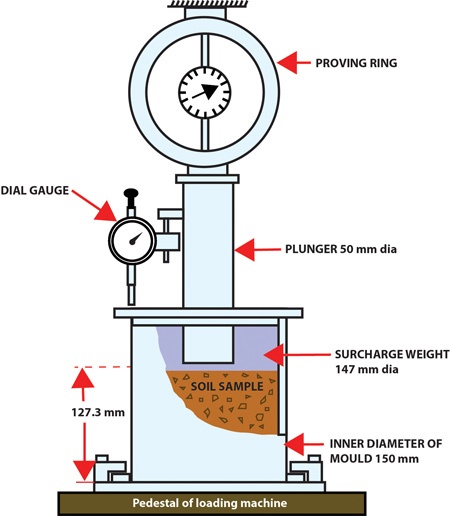

CBR Penetration Test

For penetration testing, the sample remains in the mold. With the perforated plate and the specified surcharge weights in place on the soil, the piston is seated against the test sample, and loading commences at a rate of 0.05in (12.7mm) per minute. As the piston penetrates the soil, test loads are recorded at eleven specified depths up to 0.500in (13mm).

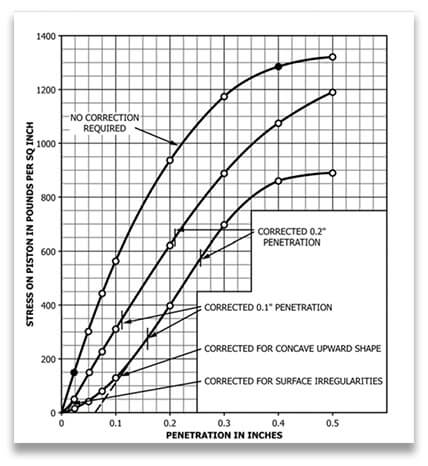

Penetrations vs. load values are plotted on a graph and corrected following the procedure specified in the test standard. Corrected stress values from penetration depths of 0.100 and 0.200in (2.54 and 5.08mm) are divided by standard stresses of 1,000psi (6.9mPa) and 1,500psi (10.3mPa), then multiplied by 100. In most cases, CBR values decrease as penetration increases. The CBR value is the stress at the 0.100in (2.54mm) penetration depth. Occasionally, the ratio at the 0.200in (5.08mm) penetration depth is higher than the 0.100in depth, and the test must be rerun. If the check test shows similar results, the stress from the 0.200in penetration depth is the reported CBR.

Field CBR Test

Field CBR testing is performed in-place on soil subgrades to determine in-place conditions of soils and bases or to confirm laboratory test results. The ASTM D4429 test method requires special CBR field equipment for loading. Soil saturation can be controlled in the laboratory but not in the field, so it is difficult to make a direct correlation between the two types of tests.

Note: This is a withdrawn ASTM standard that will be reinstated soon as a new or revised test method.

DCP Test

The Dynamic Cone Penetrometer (DCP) is another field test and often used to estimate in-place CBR values. ASTM D6951 outlines the requirements to use this test method for pavement design applications, and the measured values are widely accepted.

DCP test equipment is more portable and generally easier to set up in remote locations than the apparatus for field CBR. With this method, a cone-shaped point is driven with a sliding hammer down through soil layers, measuring penetration resistance. The DCP can also be used to characterize soil strata and relative strengths to a depth of 39in (1M) or more.

CBR Values

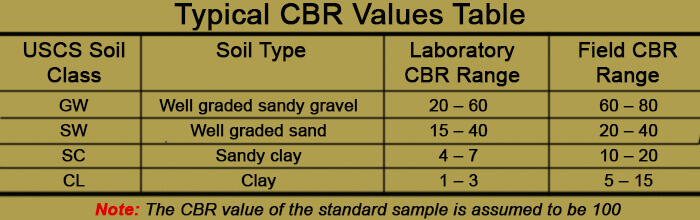

California bearing ratios of field tests represent in-situ strengths of the material under existing field conditions and will not typically correlate with laboratory CBR values of the same material. Saturation levels are near 100% for soaked laboratory samples. Field materials are often less than 80% saturated and, therefore, more resistant to penetration. The significance and use sections in the standard test methods give detailed guidance for interpretation. The chart below provides a rough idea of what to expect for laboratory and field CBR values of different soil types.

CBR Testing Equipment

CBR Lab Equipment (ASTM D1883):

- A good quality laboratory load frame with a capacity of 10,000lbf (44.5kN) or more that can operate at a strain rate of 0.05in (1.3mm) per minute is suitable for CBR penetration testing.

- Outfit the load frame with CBR Testing Components for load and displacement measurement.

- For occasional CBR testing a Load Ring, Penetration Piston, and Dial Indicator Set will suffice.

- For efficient testing of multiple samples, Gilson recommends a Digital CBR Component Set which optimizes the collection, calculation, and reporting of data. The set includes a 10,000lbf Load Cell, Penetration Piston, 2in Linear Variable Displacement Transducer, and a Two-Channel Data Readout.

- CBR Data Acquisition Software streamlines the calculation, graphing, and reporting process using real-time data collection, and plots results to ASTM/AASHTO requirements.

- CBR Test Set includes required components to perform the CBR laboratory test.

- CBR Mold

- 5lb Annular Surcharge Weight

- 5lb Slotted Surcharge Weight

- Swell Plates

- CBR Filter Paper

- CBR Spacer Disc

- CBR Swell Tripod

- 1x0.001in Mechanical Dial Indicator

- Soil Compaction Hammers for compacting soil samples for CBR testing.

CBR Field Testing Equipment (ASTM D4429):

- Penetration Piston for CBR is the same piston used for the laboratory method, but different equipment is required to provide enough resistance to load the piston.

- Field CBR Test Apparatus are various components positioned against a reaction load, such as a heavy truck or weighted framework, which applies force to the penetration piston through extension rods selected for proper spacing. Surcharge plates simulate loads from overlying materials, and a support bridge isolates the dial gauge to avoid interference from loads in the test area.

- 2-speed or 3-speed Rotary Jack

- Connectors and Extension Rods

- 10lb and 20lb Field Surcharge Plates

- Support Bridge

- 1x0.001in Mechanical Dial Indicator

DCP Test Equipment (ASTM D6951):

- Dynamic Cone Penetrometer Set (with a single or dual-mass hammer) consists of drive rods and cone-shaped tips tapered to a point at a 60° angle. A sliding drop hammer mounted on the rods forces the cones to penetrate the soil layers, and the number of hammer blows per increment of penetration indicates penetration resistance. The DCP is the best choice for remote areas or for quickly performing multiple tests in a limited time.

Resources:

- ASTM D1883 Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils is the most-often used standard for this test.

- AASHTO T 193 Closely mirrors ASTM D1883.

- ASTM D4429 Standard Test Method for CBR (California Bearing Ratio) of Soils in Place (Withdrawn 2018) Currently under consideration by ASTM for revision or replacement.

- ASTM D6951 Standard Test Method for Use of the Dynamic Cone Penetrometer in Shallow Pavement Applications. The DCP is used widely for estimations of field CBR values.

- U.S. Army Corps of Engineers (USACE) CRD-C654-95, Standard Test Method for Determining the California Bearing Ratio of Soils, covers lab or field CBR testing of soils. Replaced MIL-STD-621A in December 1995.

- Florida Department of Transportation FM 5-515 Florida Method of Test for LIMEROCK BEARING RATIO (LBR) is a test using methods and equipment similar to the CBR tests for soil materials unique to the Southeastern United States.

- British Standards BS 1377-1:2016 Methods of Test for Soils for Civil Engineering Purposes was updated in July 2016 and has nine parts. Part 4, Compaction Related Tests, includes a method for assessing the CBR value of a compacted or undisturbed soil.

- Federal Highway Administration (FHWA) Geotechnical Aspects of Pavements Reference Manual – see Chapter 5, Section 5.4, for information on the CBR Test.

- Federal Aviation Administration (FAA) advisory on Airport Pavement Design and Evaluation. For lab or field CBR testing in the design of flexible pavements for airports or airfields. See Section 2.5.6.

We hope this blog has given you some helpful information for performing the CBR test procedure.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)