- Log in

- Favorites List

-

Shopping Cart

You have no items in your shopping cart.

Materials Testing EquipmentContact Us Today! 800-444-1508

Search

Non-Destructive Testing Equipment (NDT) for Concrete

Concrete non-destructive testing (NDT) is used for quality control purposes and to assess concrete structures for strength, durability, and susceptibility to deterioration.

- Concrete Test Hammers offer fast and non-destructive estimations of the in-place strength of hardened concrete. The Gilson Test Hammer meets the same standards as the standard Schmidt Concrete Test Hammer and is a more economical model.

- Crack Monitors are easy to use and offer precise measurements of vertical and horizontal cracking in concrete bridges, roads, and buildings. Several different styles of crack monitors are available to choose from.

- Concrete Maturity Testing is a reliable way to estimate the early-age and compressive strength of in-place concrete by collecting temperatures from probes that measure the in-situ temperature profile.

- Rebar Locators and Cover Meters are designed for locating and measuring concrete reinforcing bars, welded wire mesh, and metal wall tiles in a structure to promote safe and effective recovery of test cores.

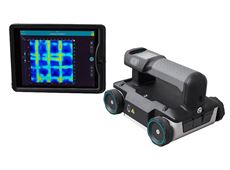

- Ground Penetrating Radar assesses the integrity of concrete structures and detects subsurface voids, reinforcing steel, and electrical services.

- Proceq Pundit Ultrasonic Pulse Velocity (UPV) Instruments send and receive a timed pulse of ultrasonic energy to assess the quality of concrete.

- Proceq Pull-Off Adhesion Testers are fully automated, with one-touch operation after programming and test disc preparation is complete. They produce accurate, repeatable results for conducting tests on bond, adhesion, or tensile strength of coatings, overlays, and substrate surfaces.

- Corrosion Measurement equipment determines the rate of corrosion in reinforcing steel to evaluate service life and assess the condition of the concrete.

- Concrete Resonant Frequency testing measures the longitudinal, transverse, and torsional resonant frequency of concrete to determine degradation due to freeze/thaw cycles. It is an alternative to cyclic load testing or ultrasonic analysis. It quickly determines Young’s modulus, modulus of rigidity, and Poisson’s ratio for freeze-thaw durability and mix-design specifications.

- Rapid Chloride Permeability Tester accelerates chloride penetration in cores or test cylinders to determine concrete’s susceptibility to deterioration.

- Concrete Coefficient of Thermal Expansion System measures concrete expansion or contraction with temperature to determine pavement performance in specific environmental conditions.

- Alkali-Silica Reactivity (ASR) Detection Kit tests for the presence of ASR in hardened concrete frequently exposed to moisture. When using recycled concrete aggregate, test results can be leveraged for mitigation purposes by proportioning concrete mixtures with additives during the design phase. Thus, preemptive ASR screening can significantly extend the life of new concrete structures and reduce the replacement and rehabilitation costs of existing structures.

- Concrete Moisture Testing evaluates the moisture conditions of concrete prior to the installation of floor coverings or tile. By determining the slab equilibrium point, costly blister and delaminations can be avoided.

- Windsor Probe Test Systems are safe and reliable for evaluating compressive strength by driving a probe into hardened concrete using a powder charge.

- Strain Gauge Set is available in standard, metric or digital models. The set includes the components needed to measure crack openings and closings, shrinkage during curing, relative displacement, strain under load, and more.

For more information on Non-Destructive Testing Equipment, here are our related blogs: