I was standing beside a significant crack in a newly poured concrete slab on a metal deck, and I must have looked deep in thought.

"Whatcha doin'?" It was a finisher with the concrete subcontractor.

"Trying to figure out why this cracked so soon," I said.

"It was only placed yesterday." He gave me a look, shrugged, and said, "Fish gotta swim, birds gotta fly, and concrete’s gotta crack," then walked away.

I thought about how I might work that into my report but decided instead to point out hot, dry winds and delays in the saw-cutting of expansion joints, among other things. What he told me, however, had a great deal of truth in it.

Cracks in concrete are so common that they’re practically inevitable. The good news is that not all of them are bad. The bad news is that sometimes it's hard to tell the difference.

So much has been written in research papers, reports, blogs, and articles about the causes and prevention of cracks in concrete that I can honestly say I don't have anything useful to add to that side of the discussion. I can help by sharing information on how to measure and monitor cracks, and how to choose the right equipment for the task.

When cracks are conspicuous, all the stakeholders in the project are immediately concerned. They worry about the potential of serious structural problems and the cosmetic impact on the structure. So, there is often an urgency to find answers and start corrective actions. What this blog post will do is offer some solutions for suitable methods and equipment to investigate cracks in concrete.

The first steps of an investigation should always focus on the basics, documenting location and dimensions. Determining the length is straightforward by using simple measuring tapes or other large-scale distance measuring tools.

Crack Width: Initial Measurement

Verifying the width of a particular crack at the beginning of the investigation sets a baseline to compare future changes in size and the rate of movement. A variety of devices can be used for initial width measurement.

- Crack comparator cards are simple, pocket-size reference cards to document crack widths in the early stages of an assessment. The clear plastic gauges are inexpensive and easy to use.

- Crack width gauges are a step up from crack comparators. These sturdy and accurate polycarbonate rules have a wide measurement range.

- Digital calipers provide precise measurements and offer additional adaptability in using the depth rod for depth measurements of large cracks.

- Optical comparators offer a level of accuracy beyond other methods commonly used for initial investigations of concrete cracking if required.

- Crack Width Microscopes and Optical Comparators offer greater resolution and accuracy beyond commonly used methods for initial investigations and monitoring of concrete cracking.

Detecting Crack Depth

As concrete cracks extend in-depth, they become progressively narrower and more challenging to measure accurately. Accurate depth measurements require instruments that look for discontinuities in the concrete to indicate the extent of a crack.

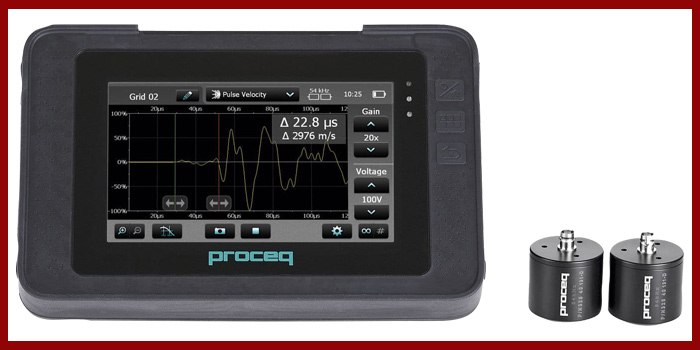

Ultrasonic pulse velocity (UPV) is one such method. UPV operates by detecting the travel time of stress waves of ultrasonic energy transmitted through concrete sections. Longer travel times through the same cross-sectional areas indicate discontinuities and potential cracking. Varying the transducer spacing between readings and noting the travel time differences allows for more accurate depth estimations. ASTM C597 describes methods and equipment required to determine the velocity of stress waves through concrete.

- Proceq Pundit 200 Ultrasonic Pulse Velocity (UPV)Tester is rugged and built for field use. Along with crack depths, the instrument performs quality assessments of concrete and can make strength estimates based on UPV readings alone or using the SONREB (SONic-REBound) method in conjunction with concrete test hammers.

Tracking Crack Movement

Locating and identifying a crack is just the start of a process. It must be monitored over time to document any changes. Continued movement or expansion of a crack are signs that the structure is not yet stable, and there is still potential for structural damage.

Just detecting movement does not call for complicated technology. Two nails driven on either side of a crack can show whether there has been movement, at least in a single dimension. What's missing with this method is the compilation of accurate data on the amount and rate of change as well as movement direction and differential displacement. All these factors can help tell the difference between a simple shrinkage crack, the beginnings of foundation failure, or (more likely) some problem in between.

Crack Monitoring: Matching the Equipment to the Task

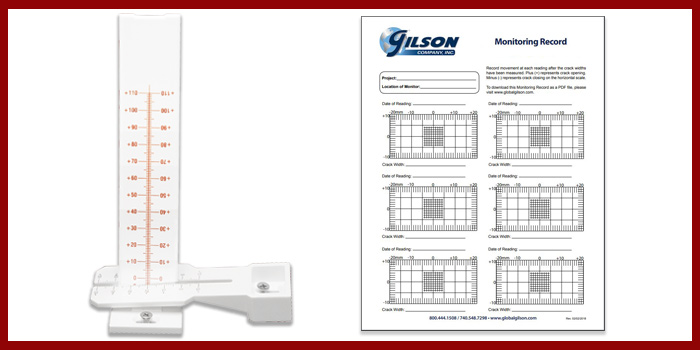

Basic crack monitors consist of two overlapping plastic tabs mounted on opposite sides of the crack to be studied. The bottom tab is white and etched with a black grid marked in millimeters. The top piece is transparent with a red crosshair. As each side of the crack moves relative to the other, scheduled monitoring of the crosshair position shows the exact amount, direction, and rate of movement.

Gilson offers crack monitoring record forms that you can download for free.

- Standard crack monitors have a grid to measure ±10mm x ±20mm from the zero point.

- Crack monitor plus units have a ±10mm x ±25mm measuring grid, plus fixtures to allow more precise measurements using digital calipers.

- Corner Adapters are accessories that allow standard or plus-model monitors to be mounted to measure movement in corners at angles from 70° to 180°.

- Concrete crack monitor kits include an assortment of crack monitors, along with mounting and measuring accessories.

Wireless Concrete Crack Data Loggers are the most accurate, efficient, and cost-effective method of monitoring crack movement in concrete or masonry structures.

The length change of a stainless steel cable winding onto or off of an electronic reel is precisely measured at a resolution of 0.00012in (0.003mm) and recorded at selected intervals of as little as 1 minute.

There is no need for manual recording of movement at frequent intervals, and operator error is eliminated. Options allow wireless data collection of width and temperature measurements from up to 32 separate monitors onto one USB stick.

- Displacement monitors measure crack propagation in the same way basic monitors do, but they add the ability to track movement in a second plane. These models have a slotted top piece for the insertion of a graduated rule to show the opening and closing of the crack, as well as differential displacement.

Displacement monitoring record sheets are available for download at no charge for the recording of data.

- Scratch-a-track motion monitors record a permanent record of continuous movement between two sides of a crack. A spring-tensioned metal stylus mounted on one side of a crack etches the direction of movement onto a coated plastic card on the opposite side.

- Crack monitor discs are stainless steel measuring points mounted with adhesive on either side of a crack. Tracking movement requires a digital caliper, and the simple, one-direction measurements may make it hard to detect lateral or differential motion.

- A strain gauge set for precision measurements is recommended where the relative movement is small, such as in shrinkage cracking. The rigid instrument frame detects movements as small as 0.0001in (0.002mm) between embedded contact points set into the concrete at a predetermined spacing.

- Crack width microscope measurements provide very precise initial readings or ongoing tracking of crack movements. The portable field microscope is fast and easy to use and does not require the embedding of contact points or measuring hardware.

We hope this blog post has given you some guidance in selecting and using methods and equipment to evaluate cracks in concrete. For a complete list of our crack monitoring equipment, visit our Concrete Crack Monitors page.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)