The Significance of ICC for Construction Materials Testing Labs

Internally cured concrete (ICC) is an effective and surprisingly simple method to ensure that cementitious materials have widespread and long-term access to curing water for full strength development. During the batching cycle, a predetermined fraction of the normal-weight fine aggregate is replaced with water-saturated lightweight aggregates (LWA) or, less frequently, with a superabsorbent polymer material.

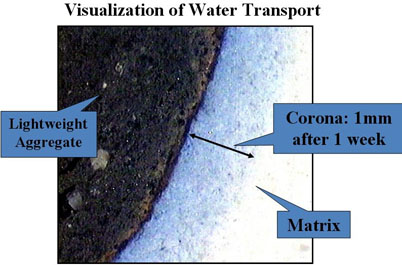

The additional water is “hidden” in the pores of the saturated LWA and does not significantly alter the water-to-cementitious material ratio (W/CM) of the mix in its fresh state. During the initial set and throughout the period of strength development, the retained water migrates out of the pores of the saturated aggregates to combine with the cementitious ingredients, continuing the hydration and strength gain process long after the concrete is put into service.

Source: https://www.escsi.org/internal-curing/

So, an ICC mix is equipped with thousands of micro-reservoirs supplying water for hydration to the concrete throughout its entire cross-section. Water is drawn out as needed during the concrete's curing process and supplied to the cement paste in a small area around each LWA particle. A sufficient volume of LWA particles ensures that these areas overlap to form a widespread structure of dense and durable concrete with low porosity. What’s more, the process can continue well beyond the standard 28-day strength development period.

By contrast, adding an external curing membrane on finished concrete only reduces water lost by evaporation. Opting for external curing by surface ponding, sprinkling, or soaked burlap only increases penetration a few inches below the surface and can only continue for a week or two at most. It is important to note that ICC does not eliminate the need for external curing but is instead a method that promotes more complete hydration.

Beyond Strength Gain: Savings in Cost and Carbon

If the only benefit of IC concrete were the optimization of strength development, it would still be worthy of consideration. The added benefits it brings to the table over conventional concrete make it a standout for specific applications.

Early-age shrinkage cracks in concrete happen when water near the surface evaporates too quickly after placement. The resulting shrinkage of the solids generates tensile stresses, causing the concrete to crack before it has developed sufficient strength to resist the movement. An accessible supply of water for hydration throughout the mix ensures that this process does not begin.

The dense, low-w/cm, low-permeability concrete mixes favored for bridge decks and pavements often have issues with self-desiccation. In this condition, the cement fraction of the mix runs out of available water, and hydration slows or shuts down. Shrinkage cracking is exacerbated, counteracting the objective of reduced permeability in the matrix. The ingress of water and deicing salts increases, and the destructive cycle of reinforcing steel corrosion and concrete deterioration is accelerated.

The reserve supplies of water in ICC mixes promote long-term strength development in general and mitigate shrinkage cracking in particular. The reduction of cracking lowers permeability, preventing corrosion of the reinforcing steel and extending the service life of the structure. According to the FHWA, these ICC mixes “… allow the production of higher-performance concrete that may last more than 75 years.”

Better Bridge Decks That Last Longer

Studies cited in ACI report PRC-308-213 report significant reductions in early-age shrinkage and subsequent cracking, a reduction in permeability, an increase in compressive and flexural strength beyond 28 days, improved dimensional stability with a reduction in slab curling, and an increase in modulus of elasticity (MOE).

Source: https://encrypted-tbn0.gstatic.com/images?q=tbn:ANd9GcQZyO0mLYmDTv_sKNjU_jU2g4tpgli_OD-n7g&s

Longer-lasting ICC bridge decks and pavements save money on materials, maintenance, and replacement costs and effectively reduce carbon emissions. ICC mixes also allow the increased use of alternative and recycled cementitious materials by reducing their tendency to produce shrinkage cracks.

Currently, ICC has been placed for bridge decks in at least 16 states. Fourteen state DOTs have initiated pilot projects for ICC use, and more are evaluating its long-term performance. Trial installations have shown a 2/3 reduction in cracking. The FHWA maintains a curated database under its Enhancing Performance with Internally Cured Concrete (EPIC2) initiative that follows current practices and documents in-service data.

Does ICC Require Special Handling or Testing?

There is a wide range of variation in the amounts and types of lightweight aggregates used in effective ICC mixes. Typically, 10% to 20% by volume of the normal weight aggregates are replaced by suitable lightweight aggregates. Fine, lightweight aggregates have proven to be more efficient at water absorption and desorption (release) than coarse aggregates.

Shale, clay, and slate materials, heated and expanded in rotary kilns, provide most of the porous lightweight aggregates used in both ICC and conventional structural concrete. These materials are produced to tight quality control standards and are readily available from specialty suppliers. The Expanded Shale, Clay, and Slate Institute (ESCSI) offers extensive technical and ICC application information for end users on their website.

While ICC mixes do require some extra steps in batching, and the stockpile moisture of LWA must be maintained, ICC is remarkably adaptable to conventional handling and placing practices. Reports from the field indicate that ICC characteristics are so similar to normal concrete that placing and finishing teams are often unaware they are placing a special mix.

Because the percentage of LWA replacement of normal-weight aggregates is so low, ICC requires no special techniques or equipment for mixing, transporting, placing, or finishing. Procedures and equipment for testing fresh concrete on-site remain unchanged compared to those for “regular” concrete. Slump, unit weight, and yield tests are performed the same way, and concrete pressure meters are permissible for air content determinations. Cylinder and beam strength samples are molded in the same manner and go through the same initial and final curing processes.

Preconstruction Testing of Lightweight Aggregates

For ICC applications, lightweight replacement aggregates may be either manufactured products or processed natural materials, such as volcanic scoria or pumice. Any material must meet the same requirements to be used in ICC. Certain tests ensure that the chemical and physical characteristics required in the specifications are met.

For manufactured LWA products, reputable producers certify compliance with two ASTM specifications: C1761 is the standard specification for lightweight aggregates (LWA) used for ICC, and C330 is the specification for LWA in structural concrete. Individual standard test methods for the qualification of these materials are cited in C1761 and C330, along with their permissible test parameters. AASHTO publishes equivalent requirements in their publication M 195.

Anytime there is a need to confirm the required chemical and physical properties or when naturally occurring materials are proposed, these tests can be performed for acceptance of a lightweight aggregate source. Most competent testing laboratories should be able to perform these standard test methods.

Tests for Chemical Composition

| Test | ASTM Designation | AASHTO Designation | Test Description |

| Organic Impurities | C40 | T 21 | Detects presence of organic impurities |

| Iron Staining | C641 | — | Evaluates potential for staining by iron compounds |

| Loss on Ignition (LOI) | C114 | T 105 | Determines mass lost when heated in a furnace |

Organic Impurities, ASTM C40/AASHTO T 21

A sample of aggregate is mixed with a 3% sodium hydroxide solution and allowed to stand for 24 hours. If the supernatant liquid is darker than a standard reference color, it indicates the presence of organic compounds, and further testing is required. An Organic Impurities Test Set, complete with the required components, is available.

Iron Staining Materials, ASTM C641

Two aggregate samples are wrapped in filter paper and cheesecloth and exposed to steam in a steam bath for a 16-hour period. The filter papers are washed in water and oven-dried. A prescribed visual method is used to classify the extent of staining on the filter paper. If the specified visual stain index is 60 or higher, the sample will be rejected if a subsequent chemical analysis detects an iron concentration greater than 1.5 mg/200 g.

Loss On Ignition (LOI), ASTM C114/AASHTO T 105

For the LOI test, a small sample is weighed on a sensitive balance and then heated to a high temperature of 950°C (1742°F) in a muffle furnace, causing some compounds to ignite and burn away. After the prescribed heating period, the sample is cooled and weighed again, and the percentage of mass lost is calculated. For lightweight aggregates, the loss must not exceed 5%.

Tests for Physical Characteristics

| Test | ASTM Designation | AASHTO Designation | Test Description |

| Clay Lumps & Friable Particles | C142 | T 112 | Determines unsuitable contaminants in aggregates |

| Particle Size Gradation | C136 | T 27 | Determines distribution of particle size fractions |

| Uniformity of Grading | C136 | T 27 | Calculation of fineness modulus |

| Bulk Density | C29 | T 19 | Maximum loose bulk density (unit weight) of LWA |

| Water Absorption & Relative Density | C1761 | M 195 | — |

| Desorption Properties | C1761 | M 195 | — |

Clay Lumps and Friable Particles, ASTM C142/AASHTO T 112

Samples with specified masses for each size fraction of coarse aggregate are prepared by spreading on a sample pan in a thin layer and soaking with distilled water. After the prescribed soaking period, the particles are squeezed between the thumb and forefinger. Particles that are broken or appear friable are separated, and their percentage by weight is subtracted from the main sample. The total percentage of clay lumps and friable particles in lightweight aggregates cannot exceed 2%.

Particle Size Gradation, ASTM C136/AASHTO T 27

Table 1 in ASTM C330 lists the gradation requirements for fine, coarse, and combined fractions of lightweight aggregates. Fractions are separated by sieving, following the ASTM C136 test method and using ASTM E11 test sieves.

Uniformity of Grading, ASTM C136/AASHTO T 27

Uniformity of grading is determined by the fineness modulus (FM) of aggregate size fractions in C136. FM is calculated using percentages of designated sieve fractions from the gradation test. For LWA, this property must remain at ±7% from the initial sample to ensure uniformity of the materials in successive shipments from the supplier.

Bulk Density, ASTM C29/AASHTO T 19

Determination of the loose bulk density, or unit weight, of LWA is determined using method C (the shoveling method) of method C29. The maximum unit weights for fine, coarse, and combined LWA are noted in Table 2 of C1761. The unit weight measure is filled with a shovel or scoop, discharging the material from 50mm (2in) or less above the top of the measure. A unit weight measure with a capacity of 14L (0.5ft³) is required.

Water Absorption and Relative Density, ASTM C1761/AASHTO M 195

The test methods for absorption and relative density of LWA for ICC are specified in C1761. Oven-dried Samples are soaked in water for 72 hours and then weighed. Surface moisture is removed using paper towels. For fine aggregate samples, a centrifuge extractor with filter rings, as specified in ASTM D2172 for asphalt extraction, is also permissible. When the sample is in the wetted surface-dry condition, it is weighed again to establish and calculate absorption.

Relative density (specific gravity) is determined by weighing the sample immersed in water in a pycnometer, oven-drying the decanted sample, and calculating the relative density. For fine aggregates, the method uses a 1L (qt) glass jar with a conical top as a pycnometer. For coarse or combined fractions of LWA, a similar 2L (2qt) container is used.

Desorption Properties, ASTM C1761/AASHTO M 195

As with the absorption and relative density tests noted above, the desorption test procedure is contained in C1761. This test determines the amount of water that can be released from the wetted aggregate in a humid environment.

A small sample of LWA in wetted surface-dry condition is placed in an environment where the relative humidity can be maintained at 94% at 23°C (73.5°F). A Moist Cabinet or a large jar containing supersaturated potassium nitrate is suitable for this purpose.

The sample is weighed periodically and reaches equilibrium when the change in mass is less than 0.01 g over a 24-hour period. The sample is then dried in an oven until it reaches a constant mass. After weighing, the mass of water released is expressed as a fraction of the oven-dry sample mass. Desorption is calculated as a percentage of the 72-hour absorption determined in the water absorption test.

Additional Resources

- Federal Highway Administration (FHWA), Enhancing Performance with Internally Cured Concrete (EPIC2)

- Expanded Shale, Clay, and Slate Institute (ESCSI), Internal Curing Overview

We hope this article has helped you understand internally cured concrete and its significance for construction materials testing laboratories.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)