The right Concrete Compression Testing Machine will shape the overall success of your concrete testing. In this guide, we explain the different machines available and how to determine the best option for your lab.

- Log in

- Favorites List

-

Shopping Cart

You have no items in your shopping cart.

Gilson Insights

Have questions about your materials testing equipment? We have the answers to these questions and much more right here! Check back monthly for long-form blog posts, how-to guides and infographics. We’ll address industry insights, the operation and maintenance of specific equipment, and our product line recommendations, all designed to better serve you.

Bookmark this page, add it to your RSS reader, or subscribe to our newsletter, so you never miss a hot topic.

Laboratory load frames perform multiple test methods on a variety of soil, asphalt, and cement materials simply by changing prescribed components used for load and distance measurements. This blog post introduces Gilson’s innovative Servo Control Load Frames and explores important considerations for selection of a suitable load frame and testing components for your applications.

For decades, rotary sifters have served as a reliable and efficient unit for particle sizing operations. Learn about the different types of rotary sifters available and how Gilson's design philosophy helped shape more advanced units that suppress noise and dust.

Knowing how to properly test and verify asphalt binders is essential to understanding how asphalt will react to various climate conditions. This guide covers the methods used to classify asphalt binders and how to perform these tests to ensure optimal pavement performance and longevity.

Increase the overall performance of your basic or manual concrete compression testing machine by upgrading to automatic operation with an Automatic Controller Retrofit. Learn more about the benefits of automatic operation and see how easy it is to install a Retrofit to your existing compression machine.

More than a century ago, Duff Abrams established a simple ratio to define the strength, quality, and workability of concrete mixtures. The water to cementitious material (w/cm) ratio is universally used in mixture design and batching, but accurate determinations for on-site acceptance of fresh concrete have remained elusive until now. The Phoenix method provides accurate and repeatable w/cm measurements in the lab or field in minutes.

Riffle splitters were a popular tool in sampling and dividing, but had limitations, such as a narrow particle size range, uneven particle distribution, and poorly divided samples. To solve these issues, Gilson designed the Universal Splitter models with adjustable chute widths, a closed hopper to evenly distribute samples, and other features to produce more accurate and efficient sampling and dividing results.

Gilson’s AutoSiever for particle sizing is the ideal solution for hard-to-separate fine powders. This blog post explores the cleaning, care, and storage of the GA-6 AutoSiever, acrylic test sieves, and latex components, along with some how-to tips for optimizing sonic sieving performance.

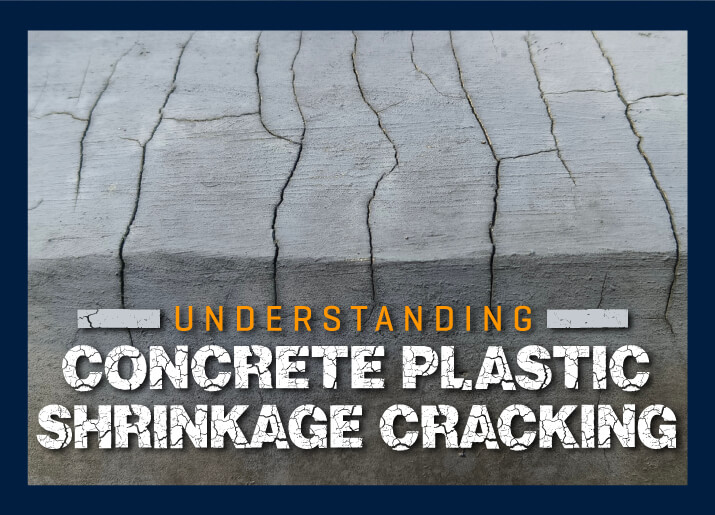

If surface moisture evaporates from freshly poured concrete too quickly, the concrete surface dries out and plastic shrinkage cracking can occur. Learn how to monitor and mitigate plastic shrinkage for optimum concrete results.

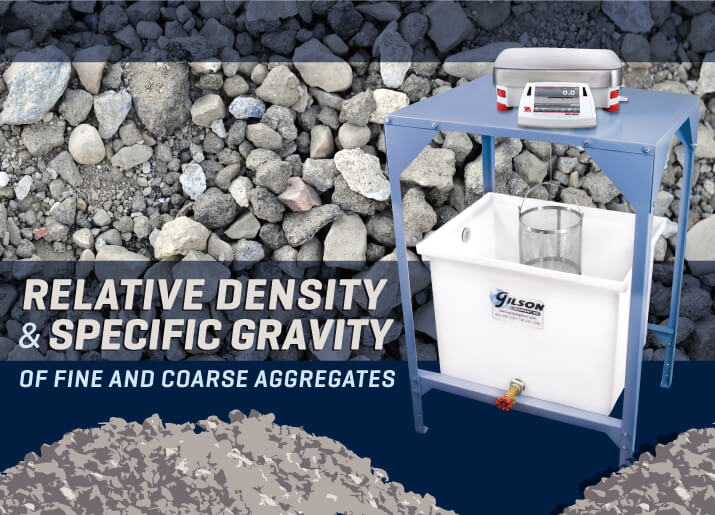

Determining relative density, or specific gravity, allows accurate conversion of volumes to gravimetric weights for proportioning materials. Learn more about relative density/specific gravity test methods and the equipment used to perform this laboratory test.

- 2026

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015