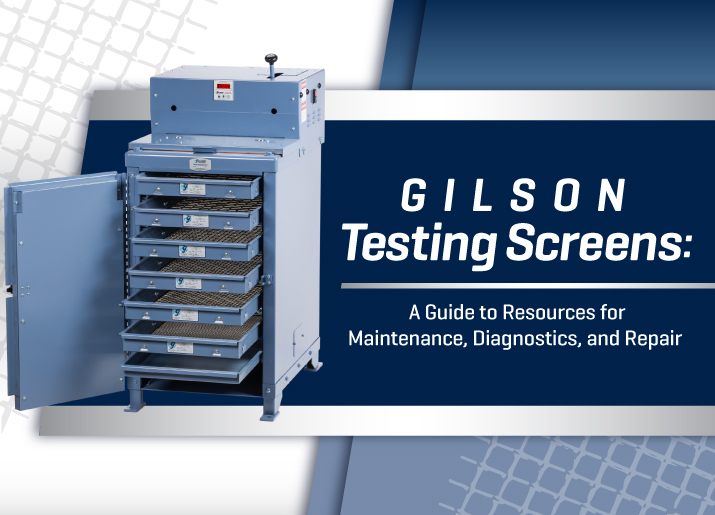

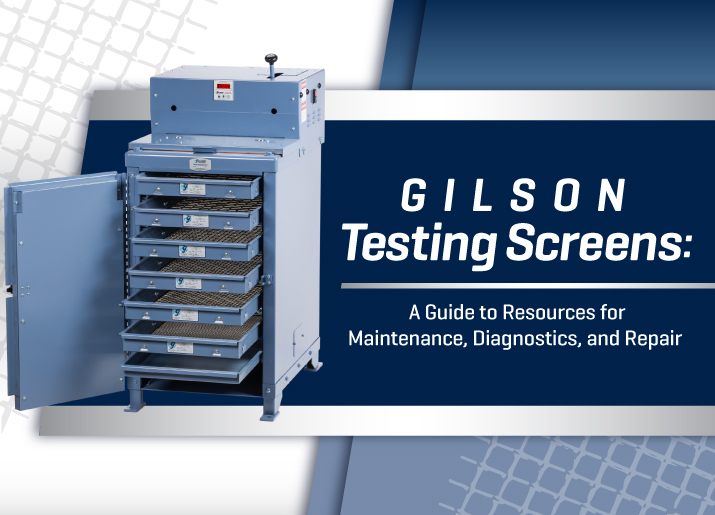

Performing regular maintenance on your Gilson Testing Screen will ensure its longevity and optimum performance. In our latest blog, we share maintenance and repair tips to maximize the service life of your device.

Have questions about your materials testing equipment? We have the answers to these questions and much more right here! Check back monthly for long-form blog posts, how-to guides and infographics. We’ll address industry insights, the operation and maintenance of specific equipment, and our product line recommendations, all designed to better serve you.

Bookmark this page, add it to your RSS reader, or subscribe to our newsletter, so you never miss a hot topic.

Performing regular maintenance on your Gilson Testing Screen will ensure its longevity and optimum performance. In our latest blog, we share maintenance and repair tips to maximize the service life of your device.

Gilson’s AutoSiever for particle sizing is the ideal solution for hard-to-separate fine powders. This blog post explores the cleaning, care, and storage of the GA-6 AutoSiever, acrylic test sieves, and latex components, along with some how-to tips for optimizing sonic sieving performance.

Verification, calibration, and performance tests all contribute to the accuracy of test sieves. Understanding sieve accuracy will ensure you get the information you need out of your test sieves or screen trays.

Particle sizing with test sieves is a hands-on process with many small, repetitive tasks that must be carried out properly. Selecting the right accessories for each job and using them correctly makes the work faster and easier, but it also significantly affects testing efficiency, accuracy, and repeatability. This article closely examines the tools that optimize test sieving procedures and ensure your sieves meet the requirements of standard test methods.

Test sieves are simple devices, but they are still scientific instruments and the most cost-effective and widely used particle sizing and gradation testing method. This blog article will cover the accuracy verification of sieves, agitation and sieve shakers, accessories, and wet-wash sieves.

Screen Trays are the heart of all Gilson Testing Screen Shakers. In this blog post, we discuss how to get the most accurate results and extended life from your testing screen trays.

In this blog, concrete air meter calibration will be broken down into everyday language in such a way where the practice won't be tough to carry out and won't take long either.

Mercury or indicating fluid separations can occur in the columns of mercury-in-glass thermometers, as well as in non-mercury thermometers. With expertise, caution and strict adherence to safety measures, the separated fluid can often be rejoined in the column by following some specific methods developed by others.

Protect and preserve costly equipment purchases through preventive maintenance – and extend their service life and functionality beyond the norm.

In order to ensure that your Gilson Asphalt Content Furnace operates smoothly for many years, we’ve outlined some maintenance procedures and tips to follow.