If you perform asphalt theoretical maximum specific gravity (Rice) tests on a routine basis, it's likely you're already familiar with Gilson's Rice Shaker. However, even if you test materials other than asphalt, you should consider if this versatile time saver belongs in your laboratory. The Rice Shaker is the key to accurate, repeatable, and efficient specific gravity determinations for asphalt, aggregates, and soils.

Specific Gravity/Relative Density: What You Should Know

Specific gravity is a fundamental characteristic of all materials used in construction materials testing. The property is applied when proportioning ingredients for composite materials like concrete or asphalt for density determinations, calculating bearing capacity and strength of soils in engineered fills, or determinations of aggregates' bulk density, absorption, and void content.

Specific gravity (SG) or the more technically accurate term, relative density (RD), are used interchangeably to describe the ratio of the mass of a material compared to the mass of an equal volume of a reference material, usually water. Specific gravity or relative density directly compares a material's density to water's density, and the resulting ratio is a unitless number.

Our reference substance of water has a specific gravity of 1.0, so materials with greater specific gravities sink, and those with a lower value float. We can bob for apples in water because their relative density is around 0.40, but limestone with an SG of 1.55 sinks like, well, a stone.

How is Specific Gravity/Relative Density Measured?

The density of water is defined as 1.0g/cc³ at 4.0°C (39.2°F). Primarily for convenience, the specified water temperatures for most SG tests range from 20°C to 25.0°C (68.0°F to 77.0°F), essentially near room temperature. A correction factor for the water density is applied when calculating test results. In the simplest test methods, the mass of sample material is determined in air and again when immersed in water:

Relative Density = B/(B-C) B = Sample Mass in Air C = Sample Mass in Water |

Individual specific gravity test methods may include variations in sample preparation, procedure, and calculations to allow further determinations of apparent relative density, average relative density, absorption, and void content.

Large-volume coarse aggregate samples or intact asphalt or concrete specimens are contained in a wire mesh basket or held in a weighing cradle when weighing in water. Baskets or cradles can be suspended from a weigh-below hook built into the bottom of many scales and balances. The suspended samples are immersed in water for mass and volume displacement determinations. Smaller samples of loose, unbound materials must be contained in flasks or pycnometers to determine the volume and immersed mass.

Removing Air from Specific Gravity Samples

Air entrapped in the sample can introduce significant errors for any density determination method. For large samples weighed by suspension in water, entrapped air can be avoided by preparing porous materials to a saturated, surface-dry (SSD) condition. Immersed samples contained in pycnometers require greater attention to remove all entrapped air, and some standard test methods require specific practices for deairing by agitation or vacuum application.

The manual deairing process requires gentle, hands-on agitation while the sample is under vacuum to release air effectively. Heating the pycnometer and its contents is sometimes used to promote a boiling action under a partial vacuum. Deairing can be tedious, but neglecting these measures directly impacts the accuracy and repeatability of specific gravity determinations.

Specific Gravity of Asphalt Mixtures

The Rice test, named after its creator, James Rice, determines the theoretical specific gravity of an asphalt mix without air voids (Gmm). In test methods ASTM D2041 and AASHTO T 209, an asphalt sample is submerged in water. A vacuum is applied to remove free and entrapped air from the container to prepare it for volumetric determination and weighing. Options for the container used in the methods include a metal or plastic pycnometer or a heavy-wall glass vacuum flask.

Many users of the early versions of the Rice test found the reproducibility of the results to be poor. Over time, researchers improved many aspects of the test, including the deairing process, to produce more reliable test results. A device that mechanically agitated the sample for a specified time under a designated vacuum was found to improve test repeatability and, as a bonus, freed technicians from the task of manual agitation.

Gilson's Innovative Rice Shaker

Early versions of Rice test agitators were crudely adapted parts cleaners with little or no control over vibration frequency or amplitude and rudimentary on/off switches. Test repeatability was still erratic, and excessive vibration levels easily or prolonged operation stripped asphalt away from the aggregate and could degrade the aggregate particles.

Gilson's SGA-5R Rice Shaker was conceived as a quality instrument, purpose-built for laboratory-specific gravity testing. The mechanical agitator applies and maintains a controlled level of agitation during the vacuum deairing of pycnometers and flasks for a variety of SG tests. The Rice Shaker allows the operator to tend to other tasks during the test cycle.

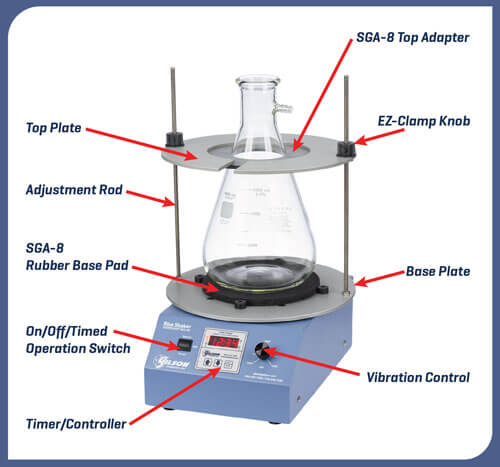

Gilson builds each Rice Shaker in-house from start to finish. The SGA-5R is powered by a variable-speed electric motor regulated with a rotating variable frequency controller. An eccentric weight attached to the motor causes the base plate to vibrate during operation. Total control of vibration frequency and intensity ensures reliable and repeatable test results, prevents sample damage from abrasion or fractures, and optimizes deairing operations.

A three-position power switch selects timed or manual operating modes. Gilson's exclusive digital countdown timer is built into the front control panel and controls the operation time of the shaker with ±0.25 second accuracy. The four-mode programmable controller features start/stop and pause/resume functions and displays up to 99:59hr: min in hours:minutes, minutes, minutes:seconds, or seconds. A special Texas model, the SGA-5RT, has modified vibration characteristics that meet Texas DOT requirements for test method TEX-227-F.

Gilson's exclusive EZ-Clamp system secures all of the specific gravity vessels with the push of a button and a quick twist of the clamping knobs. Specific gravity vessels are easily mounted to or removed from the Rice Shaker with lids, fixtures, and vacuum lines in place. An EZ-Clamp Upgrade Kit is available to convert older Gilson Rice Shakers to the EZ-Clamp system.

A Device for All Specific Gravity Applications

The asphalt Rice test is not the only procedure in construction materials laboratories that combines the application of a vacuum with agitation for deairing. The same sample immersion and deairing process for weighing and volume determinations is also used in specific gravity tests for aggregates and soil.

Pycnometers or filter flasks are positioned on the base plate and secured with the EZ-Clamp system on a top plate between two upright rods. The base and top plates accept SG-16A and SG-18A Aluminum Pycnometers, and available adapter sets modify the shaker to fit additional pycnometers and various glass vacuum or volumetric flasks.

NOTE: Review individual test methods to confirm the allowable use of mechanical agitators.

| Pycnometer Type | Gilson Model | Required Adapter | Sample Material | ASTM | AASHTO |

|---|---|---|---|---|---|

| 2,000g Aluminum | SG-16A | Included | Asphalt | D2041 | T 209 |

| 4,000g Aluminum | SG-18A | ||||

| 6,000g Plastic | SG-15 | SGA-7 | |||

| 1,000mL, 2,000mL, or 4,000mL Thick-Wall Glass Flasks | GW-74, GW-75, GW-76 | SGA-8 | |||

| 1qt Glass Jar & Top | SG-2 | Fine Aggregate | C128 | T 84 | |

| LeChatelier 250mL Glass Flask | SG-24 | Hydraulic Cement | C188 | T 133 | |

| 100mL, 250mL, or 500mL Glass Volumetric Flasks | SG-100, SG-250, SG-500 | Soil | D854 | T 100 |

Gilson Accessories Improve Precision

Optional accessories monitor vacuum levels in the vessels, and models that regulate vacuum and measure shaker energy are available.

- Gilson's unique Digital Residual Pressure Manometer adds another layer of accuracy and repeatability. This mercury-free digital manometer displays instant absolute vacuum pressures from 0 to 1,000 mm/Hg with 0.1 mm/Hg readability. The Digital Residual Pressure Manometer is also available with NIST Traceable 3-point Certification.

- AutoRice™ teams up with the Rice Shaker to create the ideal asphalt specific gravity testing system. The digital controller automatically measures and regulates the applied vacuum pressure and time to ensure consistent deairing with minimal attention. The AutoRice™ can also be outfitted with a vibration sensor to measure the amplitude and frequency of the shaker to establish optimum settings for consistent results.

- The PumpSaver Air Dryer works with the AutoRice or any vacuum system to eliminate moisture and prevent damage to expensive vacuum pumps.

- Vacuum pumps or aspirators aid in deairing samples during agitation and have many other applications around the lab.

- An Air/Gas Dryer removes moisture from evacuated air. Installing one in the line between the vacuum pump and the pycnometer protects the pump against moisture damage.

Test Standards

AASHTO T 84, Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate

AASHTO T 100, Standard Method of Test for Specific Gravity of Soils

AASHTO T 209, Standard Method of Test for Theoretical Maximum Specific Gravity and Density of Asphalt Mixtures

ASTM C128, Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate

ASTM D854, Standard Test Methods for Specific Gravity of Soil Solids by the Water Displacement Method

ASTM D2041, Standard Test Method for Theoretical Maximum Specific Gravity and Density of Asphalt Mixtures

ASTM D4867, Standard Test Method for Effect of Moisture on Asphalt Mixtures

We hope this blog post has helped you discover the versatility of our SGA-5R Rice Test Shaker.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)