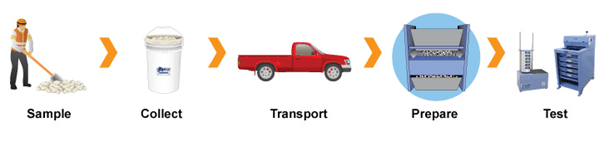

In Part 2 of this 3-part series, we addressed how to properly prepare bulk field samples for testing in the lab, necessary equipment, and helpful tips. Now that you understand how to perform all the pre-work on samples prior to testing, we’ll cover test procedures for effective determination of the particle size distribution of coarse aggregates.

Particle size determinations on large samples of aggregate are necessary to ensure that aggregates perform as intended for their specified use. A sieve analysis or gradation test determines the distribution of aggregate particles by size within a given sample. This information can then be used to determine compliance with design and production requirements. Data can also be used to better understand the relationship between aggregates or blends and to predict trends during production.

Procedure Overview

A known mass of material is placed on top of a group of nested sieves (arranged in order of decreasing size from top to bottom) and mechanically shaken for a designated period of time. After shaking is complete, the operator weighs the material retained on each of the sieves using one of two methods:

- Cumulative method – Each sieve fraction, beginning with the coarsest, is placed in a previously tared pan and weighed. This process is repeated until all fractions and the bottom pan have been added, weighed, and recorded. This is a good time-saving option since you don’t have to empty out or tare the pan on the scale for each fraction.

- Fractional method – The operator weighs and records the contents of each sieve fraction separately.

The technician then calculates the amount retained and passing the sieve to the nearest 0.1% by the total mass. The calculation is performed as follows:

- Cumulative method – For each retained fraction added, divide the cumulative mass by the mass of the total sample and multiply by 100 to calculate the percent retained. Subtract the cumulative percent retained on a given sieve from 100 to calculate percent passing.

- Fractional method – Divide the mass retained on each sieve by the total and multiply by 100 to calculate the percent retained. Calculate percent passing by subtracting the percent retained on the sieve nested beneath.

Gradation, or particle size distribution, is the dispersal of individual particle sizes across the entire sample. Aggregate gradation is typically reported in graphical form by plotting each of the particle sizes on a semi-logarithmic chart and drawing a best-fit curve between the points.

The full procedure is outlined in ASTM C136 (AASHTO T-27).

Recommended Equipment

- Gilson Testing Screen and Gilson Test Master® Testing Screen offer accurate particle size separations Both are designed for coarse materials of mid-range density such as limestone or gravel aggregates. The Test-Master features quieter stable operation and easy sample introduction via an integrated hopper.

- Gilson Porta Screen is an effective alternative to the equipment options above but takes up less space while efficiently processing materials down to No.200 (75μm).

- Sieve Shakers are another option for coarse materials up to 1 or 2in, depending on the shaker. Check out our guide to select the appropriate model for your application.

- 12in Sieves are best for coarse size fractions if Testing Screens are not used.

- High-Capacity Balance to weigh the total sample and separated fractions.

- Clean-N-Weigh Accessory is helpful for processing fraction weights. The chute-end handling pan used for collection can be positioned directly onto an electronic balance for immediate collection of fraction weights. If the balance is connected to a computer, data can go directly to a spreadsheet for calculation and reporting.

Testing Tips

- Avoid overloading sieves. The total material retained on a sieve at completion should be less than one to two layers deep. More will cause blinding of the mesh and inaccurate results. If needed, an additional coarser sieve can reduce the load on sieves below. For coarse aggregates, ASTM C136 specifies that mass retained in kg shouldn’t exceed the product of 2.5 × (sieve opening, mm × (effective sieving area, m2)).

- Allow enough time on a sieve shaker or testing screen for complete separation. For materials that have not been processed previously, a rule of thumb is to weigh the fraction, process for an additional minute, and weigh again. If the difference in percent passing exceeds 1%, add an additional minute and repeat until the difference is less than a percent.

- Watch for degradation. Some brittle or friable materials can break apart during separation, leading to inaccurate results.

- Consider reducing shaker time intervals or using a different method.

- Check sieves for wear, torn mesh, or distorted openings regularly since this can bias test results.

- Do not use tools or probes to dislodge trapped particles since this will damage the mesh.

- Take care when transferring material to the tare weighing pan (loss of material affects results).

- Don’t forget to pre-dry your sample.

We hope this blog post will help guide you in the effective determination of the particle size distribution of coarse aggregates.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)