Picture the scene. You arrive at your lab following lunch on a Thursday afternoon only to find 30 to 40 bags of construction aggregates blocking the door. A note from your supervisor says, “Need gradation curves on all these samples whenever you can get to them, as long as they’re done by tomorrow.” As your lab techs move into “all-hands-on-deck” mode, you’ll find the techniques outlined in this blog to be quite effective when managing an unexpected influx of particle size analysis samples.

Gradation of Aggregates

Sieving for particle size distribution is the primary test requested for construction aggregate samples. Whether field samples are being tested to evaluate a new aggregate source or just coming in as part of day-to-day quality control of production, particle size distribution is a primary consideration. If processing and sieving are not handled efficiently, it creates a backlog. Schedules are thrown off, bags and buckets pile up, and worst of all, clients aren’t getting what they want when they want it. The following methods will help ensure the job is done effectively and quickly.

Dry it Up

Bulk aggregate samples often arrive at the lab with moisture content too high for immediate handling and testing. The sooner they are dumped out and spread into flat, shallow trays, the sooner initial drying can begin. Large-capacity laboratory ovens or air drying ovens are ideal for fast drying, but for initial drying, the materials can also be placed in open, well-ventilated areas or even outside in the sun if conditions are right. It is often a bit quicker to initially dry the bulk samples enough to be split to testing size.

Oven-drying the aggregate sample

Final oven-drying will then be faster and sample sizes will be easier to handle. In the ASTM C136 test method, samples for acceptance testing must be oven-dried to constant mass at 110 ± 5 °C (230 ± 10 °F), but control and production test samples of coarse aggregate need not be fully oven-dried

Time to Split

As noted above, bulk aggregate samples should be split down into smaller representative samples as soon as practicable. Smaller volumes of samples dry faster and are more convenient to handle. ASTM C702 allows fine aggregate to be divided with a mechanical splitter if the material is drier than saturated surface-dry (SSD). For non-specification testing of some free-flowing aggregates with low fines content, you could consider splitting while still wet, but it can get messy. Coarse aggregate samples can be split at any moisture.

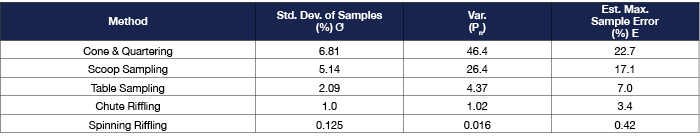

Gilson strongly recommends using mechanical sample splitters to reduce bulk samples to testing size. Mechanical splitters use chute riffling for faster and more efficient processing of aggregate specimens and produce a representative sample that up to five times more accurate than a manual scoop or cone-and-quarter method. The table below offers a comparison of sample dividing methods.

Wet it Down

Wet-washing aggregate specimens according to ASTM C117 is a process that removes materials finer than 75µm (No. 200) from the sample material. The fraction of the sample removed in this process is often referred to as P200, as in the fraction passing the No. 200 (75µm) sieve. Wet-washing can take some time and effort, but there are a couple of reasons you may decide to use this procedure:

- You want to

- You have to

Fine aggregate samples or samples of unprocessed mixed-size material from natural deposits sometimes contain a high proportion of fines. The extra fines make handling, sample dividing, and sieving difficult, and needlessly generate a lot of dust. In this case, washing is a matter of convenience and housekeeping. Coarse aggregate samples may not require a P200 determination at all, but it still may be helpful to wash them.

On the other hand, an accurate P200 value may be an important focus of the requested gradation tests, especially with fine aggregate specimens. The minus No. 200 fractions is an important consideration for final mix designs of both concrete and asphalt materials. The specifier will require it because it is a reliable and efficient method to determine an accurate number.

The C136 test method notes that an accurate minus 75µm (No. 200) fraction cannot be determined unless the ASTM C117 practice is incorporated into the gradation test. These two tests work together when needed, and the removal of the fines from the total mass of the sample is mathematically corrected when calculating results. Wet-washing requires repeatedly agitating the sample in water, then decanting the wash water over the No. 200 sieves. By using a mechanical aggregate washer, you can perform this task continuously, thus saving considerable time in the sample preparation process.

Wet-washing the aggregate sample in a test sieve

Making the Grade

Most gradation tests for construction aggregates indicate that compliance grade test sieves are acceptable for testing. These off-the-shelf sieves comply with basic manufacturing tolerances noted in ASTM E11, but the opening sizes of the individual sieves have not been directly measured. Having two or more sets of these sieves in use at the same time is a cost-effective way to speed up the sieving process. One set can be working in the sieve shaker while separate fractions from the other are weighed and recorded.

Shaking the aggregate samples through the sieves by hand is permissible in most test methods, but very time-consuming, with poor repeatability. Sieve shakers for standard round test sieves and testing screens for large samples of coarse aggregates automate the separation process, adding better accuracy while freeing up lab personnel for other tasks.

Most of the time, you have the option of weighing and recording the separated material retained on individual sieves using either the cumulative or fractional method as explained in our video, The Cumulative Method and the Fractional Method of Sieve Analysis of Fine and Coarse Aggregates. This simply means that in the fractional method, you place each separated portion on the balance, determine the mass, and remove it before weighing the next fraction.

For cumulative weighing, place each fraction on the balance to weigh without removing the previous portion. Individual fraction weights are calculated later if the total weight displayed is allowed to accumulate. Electronic balances can be tared between each fraction and the mass of the individual fraction recorded.

Clean and Weigh Accessories

Cleaning the separated fractions out of each sieve is repetitive work, but this process needs to be done thoroughly and consistently to ensure accurate test results. Choosing the correct accessories can increase efficiency and improve test repeatability.

- Clean-N-Stor or Clean-N-Weigh - Each device offers a funnel-shaped platform where a sieve (Clean-N-Stor) or screen tray (Clean-N-Weigh) can be inverted, emptied, and brushed out. The material is collected in a pan or scoop positioned below for weighing. For optimum efficiency, some of these devices can be positioned directly over an electronic balance for instant weight determinations.

- Selecting the proper sieve brush for cleaning can make a big difference. The rule of thumb here is that fine bristles for fine sieves avoid damage to the wire cloth and coarse bristles for coarse sieves dislodge larger particles. And please...don’t use screwdrivers or ice picks to clean out your sieves!

- Digital Scales and Balances to weigh samples and fractions are in wide use internationally. These instruments can increase efficiency and reduce operator error. Data collection directly from an electronic balance for recording and calculating results in a software application is optimized for speed, but testing can still be performed efficiently with manual data entry to a spreadsheet. Simple formulas are easy to insert into Excel or other ASCII spreadsheets to calculate and graph sieving results.

Looking for additional information? The links below are accessible on Gilson’s video library – a fantastic media resource on methods and equipment for sieving and sample dividing:

- Tips for Dividing Aggregate Samples

- Standard Practice for Reducing Samples of Aggregate to Testing Size (ASTM C702, AASHTO T 248)

- Gilson Automatic Aggregate Washer

- Test Sieves

- Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates ASTM C136

We hope you find a trick or two in this blog post to streamline your aggregate gradation testing.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)