What Is A Rebound Hammer?

Concrete Test Hammers are also known as Swiss Hammers, Schmidt Hammers, or Rebound Hammers. They are versatile tools for assessing the quality of hardened concrete. Although commonly used to estimate in-place compressive strength, concrete test hammers can provide much more value. The complete evaluation of a concrete structure or pavement is about more than just strength. The hammers are portable and easy to use, and their long history of widespread use means that performance and results are well understood.

Who Invented The Rebound Hammer?

The concrete test hammer was invented in 1954 by Ernst O. Schmidt, a civil engineer in Zurich, Switzerland, and commercially developed by Antonio Brandestini through Proceq, the Swiss company he founded. Proceq continues to be a leader in the production and advanced development of this technology, but test hammer devices are available from numerous manufacturers.

An early design of the Schmidt Hammer

Photo Credit: www.schmidtundpartner.ch/wir/

When To Use The Rebound Hammer

Testing hardened concrete in place is often necessary to determine the suitability of a structure for its intended use. Existing structures must be assessed for structural integrity after years of exposure to harsh environmental conditions and other stresses. Nondestructive evaluations of buildings and pavements still under construction catch deficiencies in materials while there is still time to fix them.

Rapid and efficient collection of concrete uniformity and quality data in both new and existing construction is the test hammer's strong suit. A simple testing program creates an overall picture of concrete quality, highlights areas with lower strength, and isolates areas damaged by freezing or fire.

What is the Rebound Hammer Test?

A straightforward analysis of test hammer data allows quick, cost-effective, and informed decisions on structural suitability. A broad assessment of a structure with a test hammer is a cost-effective way to decide if a more in-depth testing program is needed. Reliable compressive strength measurements are possible using correlation data from laboratory tests. It is important to note that ASTM C805 states that rebound values cannot be used as the basis to accept or reject concrete.

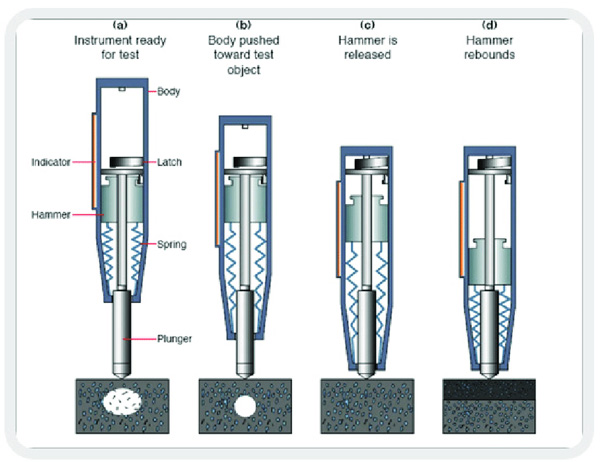

Pushing the test hammer's piston against the surface of hardened concrete loads a spring mechanism until it trips and releases a hammer mass. The mass strikes the piston, which impacts the concrete with a defined amount of energy. As the hammer mass bounces back, a sliding indicator records the rebound number (R-value) on a simple linear scale. Schmidt found that these measurements of surface hardness can indicate relative strength when compared to laboratory test results.

Photo Credit: www.researchgate.net

Selection and Preparation of Test Areas

Factors directly affecting rebound numbers include moisture, surface texture, age, carbonation depth, and the proximity of aggregate, steel reinforcement, and air voids, so care must be exercised when selecting and preparing test areas.

High moisture content lowers the rebound readings of concrete compared to the same concrete when dry. If estimating compressive strength through correlation with cores or cylinders, the test surface should be saturated with water several hours before rebound readings are taken. The correlation specimens should be tested in a saturated, surface-dry (SSD) condition.

The rebound number measures surface hardness, so textured or soft areas require surface preparation before testing. A carborundum stone for manual surface smoothing is often adequate, but some areas may need a surface grinder for preparation. Damage to the concrete from rebound testing is minimal, often leaving just minor dimples on the surface.

What are the Types of Concrete Test Hammers?

Two different versions of concrete test hammers generate different impact energies:

- Type N test hammers have an impact energy of 1.63ft-lbf (2.207Nm) that allows for testing of a wide range of concrete elements and structures. Type N hammers are used on concrete with thicknesses greater than 4in (100mm) and in-place strengths of 1,450 to 10,152psi (10-70mPa). They have limitations for applications where concrete cross-sections are thinner or on "green" early-age concrete with lower strengths.

- Type L rebound hammers test concrete in similar compressive strength ranges as Type N models but generate a lower impact energy of 0.54ft-lbf (0.735Nm). These models provide more repeatable values when testing green concrete or areas less than 4in (100mm) thick. They are Ideal for precast pipe or checking early-age concrete for form removal or post-tensioning operations. Type L hammers also reduce cosmetic and structural damage to concrete with thin cross-sections. One Type L model is the Type L Silver Schmidt Hammer can be fitted with a Mushroom Plunger accessory that allows accurate rebound tests on low strength or green concrete with compressive strength as low as 725psi (5mPa).

Strategies for Effective Concrete Assessment

Performing multiple rebound tests at different locations on a structure helps piece together a picture of overall concrete quality, uniformity, and relative strength. Areas with low rebound numbers can be slated for closer examination and testing with Ultrasonic Pulse Velocity Tester measurements, Windsor Probe penetration tests, or other non-destructive testing equipment techniques. Drilled cores can be taken in critical areas to measure compressive strength directly, while zones showing higher strengths can come under less scrutiny.

If the goal is to estimate in-place concrete strength, the testing laboratory must establish the relationship between R-values produced by a particular instrument and compressive strength. ASTM C805 and American Concrete Institute (ACI) provide detailed guidance for this procedure using drilled cores or concrete cylinder samples. Cores or cylinders are clamped between the platens of compression testing machines; then rebound hammer impact tests are performed on the specimens just before breaking them for compressive strength values.

Researchers have found that combining two different testing techniques produces more reliable compressive strength estimates. The SONREB (SONic-REBound) method uses an algorithm to correlate impact data from the test hammer and compression wave velocities from ultrasonic pulse velocity (UPV) instruments with existing compressive strength test results. The method provides correction values that allow either device to estimate strength accurately. ASTM C597 describes procedures for using pulse velocity meters on concrete, but there is not yet an ASTM or AASHTO test procedure for the SONREB method.

Many rebound hammers still include a chart converting rebound numbers to a specific compressive strength in psi or mPa. This information does not account for differences in mix design, surface moisture, and other factors and is only useful to indicate relative strengths between different test locations.

Advances in Technology Produce Better Results

More sophisticated rebound hammers have followed innovations in contemporary electronic instrumentation and software on multiple platforms.

Modern test hammers like the Schmidt Hammers capture traditional R-value impact energy measurements with accelerometers, then process, calculate, and store results to eliminate manual recording. GPS positioning, notes, images, and audio comments can also be stored to enhance the testing program's details. Wi-fi and cellular technology and cloud-based connectivity allow immediate distribution of test results to stakeholders, right from the job site.

The most advanced units like the Silver Schmidt Concrete Test Hammer use optical encoders to determine new "Q" impact values. Measurements from these encoders are unaffected by internal friction or impact angle, enhancing repeatability and extending the range of concrete strengths that can be tested. Using correlation curves developed by the operator, Q-values are effective on ultra-high performance concrete (UHPC) with compressive strengths up to 17,405psi (120MPa).

Rebound hammers for geological and geotechnical applications test the strength and consistency of rock formations. These unique models evaluate age, weathering, and strength in rock formations or estimate penetration rates for tunnel boring machines.

Whether you select a simple or advanced model, the concrete test hammer is versatile, reliable, and efficient; a valuable tool and a time-saver to help in the complete assessment of hardened concrete structures.

We hope this blog article has helped you understand the rebound hammer test. Read more about our concrete test hammers and their usefulness as part of a complete nondestructive evaluation of hardened concrete structures.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)