Optical/microscopic examination and measurement of Inspection Grade or Calibration Grade test sieves are the only way to directly verify that opening sizes and wire diameters conform to published standards such as ASTM E11 or ISO 565. Sieve Verification Services ensure the specified dimensions are met, but ongoing maintenance of the verified status does require removing the sieves from service for shipment to the Verification Laboratory.

The use of Standard Reference Materials (SRM’s) makes it possible to calculate the effective size of openings simply by sieving the material on the subject sieve. SRM’s or user-prepared reference materials are also useful for direct comparisons between a previously calibrated (inspection or calibration grade) test sieve and a working sieve to establish comparative values. Although reference materials only provide indirect determinations, they are a satisfactory way to evaluate compliance.

How Reference Materials Help Ensure Quality Control of Sieves

ASTM E2427, Standard Test Method for Acceptance by Performance Testing for Sieves, offers a standardized path to implement these practices but is often overlooked as a useful tool for internal quality control programs. This method compares the performance of a working sieve against that of an inspection or calibration grade reference sieve using either SRM’s or user-prepared reference materials.

The focus of the test method is to measure and track the performance of individual working sieves, but it also provides an excellent means of checking the sieving sufficiency of the sieve shaker and can be a step toward standardizing multiple sieve sets against a master set, as described in an earlier Gilson blog post, 5 Simple Steps to Setting up a Flawless Quality Control Program.

The reference material is processed in turn on the reference sieve and the working sieve in the same sieve shaker used for normal testing. The difference between percentages retained by the reference sieve and working sieve is compared to the user-established tolerance to determine acceptability.

After initial processing on the reference sieve, it is generally not necessary to repeat this step each time a performance test on a working sieve is run, if the same reference batch is used and the material has not degraded. These regularly scheduled in-house performance checks are cost-effective, convenient, and offer a way to indirectly monitor changes in sieve performance as affected by ongoing wear.

User-Prepared Reference Materials vs Standard Reference Materials (SRMs)

User-prepared reference material is readily available, and the source should be plentiful. For greatest accuracy and repeatability, testing fractions should be prepared from bulk materials using a spinning riffler or riffle-type splitters. Manual “cone and quarter” sample dividing methods produce a high rate of variability in samples and may introduce error into the process. The material selected for the reference batches should not be prone to degradation or dusting. If the batches are created from the same material being tested in daily operations, they will have all of the same characteristics, and results are likely to be more predictable.

On the downside, user-prepared materials require a considerable investment of time and effort. They are non-standard, not directly traceable to any source, and can be more difficult to duplicate and verify for regular re-evaluations.

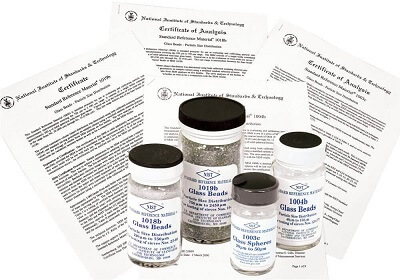

So, while there are advantages to using available materials you regularly work with, there’s also the other option: Standard Reference Materials. SRM’s for sieves are most often calibrated spheres of specially produced soda glass material in the form of beads or powder. Selected and precisely sorted by size, they include traceable documentation for particle size distribution and information to determine the effective opening size of a test sieve.

SRM’s are produced on equipment traceable to the National Institute of Standards and Technology (NIST) or the European Community Bureau of Reference (BCR) and carefully checked for exact particle size distribution. The samples are packaged in convenient sizes for direct dispensing onto sieves to minimize loss and operator error. To be fair, SRM’s have a few limitations. They are expensive and can only be used a limited number of times. The traceable certifications carried by SRM’s often have an expiration date, whether or not they are used.

Reference materials do not yield precise opening sizes and wire diameters, but periodic use establishes a pattern to monitor when a sieve might drift out of compliance. When performance results start dropping off, the sieve can be shipped off for optical examination to verify non-compliance or simply replaced. Additional information about Gilson’s laboratory verification service is available here.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)