The purpose of a Concrete Compression Machine is straightforward; it uses a simple welded steel load frame to direct compressive force onto different types of concrete specimens to ensure that the material meets design and structural strength requirements. These versatile machines are the centerpiece of any concrete testing lab, and they can be configured in a variety of ways to adapt to different sample types or test methods. The right compression machine can shape the success of your concrete testing program.

Modern Compression Machines Optimize Testing Efficiency and Data Management

Technical advancements over time have enhanced the level of accuracy, efficiency, and data handling for testing concrete, grout, and mortar strengths in a wide range of sample types. These precision machines are often equipped to test one specific sample type, for example, a 6x12in concrete cylinder specimen. However, they can be outfitted with adaptive accessories for testing multiple sample types and sizes.

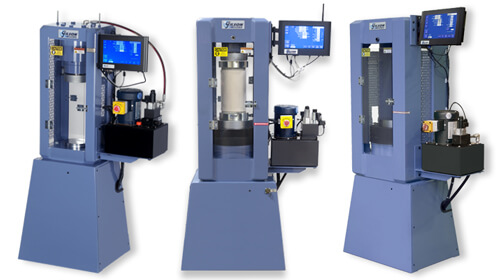

Gilson concrete compression testing machines are engineered to meet the requirements of ASTM C39 and AASHTO T 22 and are offered in two unique control and drive configurations; Basic or Automatic.

New Rigid Frame (RF) Series compression machines share the same loading and control systems as the Automatic Series, but feature a stiff frame for safety, durability, and accuracy. Each system has its own advantages and features.

| Compression Machine Features | Basic Compression Machines | Automatic & RF Compression Machines | Modulus of Elasticity Option1 | Poisson's Ratio Option1 |

|---|---|---|---|---|

| Exceeds ASTM and AASHTO standards requirements | ✓ | ✓ | ✓ | ✓ |

| Variety of load frame strength capacities | ✓ | ✓ | ✓ | ✓ |

| Versatility to perform multiple test types | ✓ | ✓ | ✓ | ✓ |

| Predefined selectable test protocols control machine operation | X | ✓ | ✓ | ✓ |

| Load frame rigidity meets ACI 363 recommendations | ✓ | ✓ | ✓ | ✓ |

| One touch activates complete test cycle | X | ✓ | ✓ | ✓ |

| Memory stores multiple test results for printing or downloading | ✓ | ✓ | ✓ | ✓ |

| Live display of multiple values during a test | ✓ | ✓ | ✓ | ✓ |

| Precise automatic control of specimen preload rates | X | ✓ | ✓ | ✓ |

| Precise automatic transition to controlled loading rate | X | ✓ | ✓ | ✓ |

| Automatic detection and recording of peak specimen load | ✓ | ✓ | ✓ | ✓ |

| Automatic unloading and piston return to the home position | X | ✓ | ✓ | ✓ |

| Minimal operator intervention to optimize testing efficiency | X | ✓ | ✓ | ✓ |

| Overall accuracy better than 1% | ✓ | ✓ | ✓ | ✓ |

| Elimination of operator error in data collection | X | ✓ | ✓ | ✓ |

| Model optimized for Modulus of Elasticity testing¹ | X | X | ✓ | ✓ |

| Model optimized for Poisson’s Ratio testing¹ | X | X | X | ✓ |

| Energy-efficient drive systems | X | ✓ | ✓ | ✓ |

| Quiet operation | ✓ | ✓ | ✓ | ✓ |

| Cooler operation for consistent oil pressure and longer component life | ✓ | ✓ | ✓ | ✓ |

¹Requires specimen testing fixtures purchased separately.

Basic Compression Machines require manual control of both the initial load application and the transition to the preset metered load rate specified for final testing. Testing with these machines must be performed by a human operator, present throughout the test cycle. These rugged models are a cost-effective solution for labs with a moderate sample load of concrete strength specimens.

Models are available with capacities from 250,000 to 450,000lbf (1,112 to 2,016kN) and meet relevant ASTM and AASHTO standards. Accessories for testing cores and cubes, performing tensile splitting tests, and breaking flexural beams are available for each model. The frame is constructed with solid steel crossheads for rigidity and exceeds American Concrete Institute (ACI) 363 recommendations for stiffness. Safety features include an emergency stop button and hinged fragment guard doors that latch securely for operator safety.

Basic Concrete Compression Testing Machines feature digital controllers that allow users to enter test protocol, view force, stress, and rate of load, and print or transfer test data. Live data graphing of load vs time or stress vs strain can be viewed during testing. Basic models are compatible with the Gilson Guardian Cloud Sharing Application and can be converted to fully automatic operation with an Automatic Controller Retrofit.

Automatic Compression Machines feature electronic sensing and software controls to regulate loading, load rates, break detection, and test protocols. ASTM/AASHTO standard test methods are selected from a menu, the test specimen is positioned in the machine, and the loading program is initiated. No further input from the operator is required until the test cycle is completed and the specimen is removed.

Automatic compression machines have some clear benefits:

- Strict compliance with standard test methods is ensured.

- Automated control maximizes accuracy and repeatability.

- Speed and volume of sample throughput are improved.

- Human operators are free to make notes, prepare the following sample, or perform other tasks.

The programmed electronic controller closely regulates the integrated electric motor and hydraulic loading system, so the system uses only enough energy to meet loading and rate control demands. Operation is accurate, energy efficient, and exceptionally quiet.

Gilson Automatic Compression Machines are fully compatible with the Gilson Guardian Cloud Sharing Application. The automated system optimizes data collection, sample tracking, and testing and report distribution to project stakeholders. Sample ID, test method and results data, and operator and client identification are all stored automatically so that custom reports can be generated.

Rigid Frame Automatic Compression Machines share all the same loading, regulation, and automation features of the Automatic Series machines, including compatibility with the Gilson Guardian Cloud Sharing Application. The unique design and materials used for this series result in a highly rigid load frame, more than three times stiffer than conventional compression machines. Safety, durability, and accuracy are the major advantages of this design.

The American Concrete Institute (ACI) 363.2R Guide to Quality Control and Testing of High-Strength Concrete points out the advantages of a stiff load frame for compression testing of concrete.

- The frequency of explosive sample failures is reduced on frames with greater longitudinal stiffness, especially when testing higher-strength concrete and using unbonded capping systems.

- Longitudinally stiff frames last longer than conventional frames under the same load conditions. Elastic deformation of frame members, welds and fitments is reduced, and service life is increased.

- Laterally stiff frames compensate for minor loading errors made in aligning test specimens and for inconsistencies in the sample. Lateral stiffness aids in producing consistent, repeatable test results.

The RF series compression machines also feature safety doors that completely enclose the testing chamber to protect from dust, noise, and flying debris. The doors are fitted with heavy-duty latches, hinges, and a shatter-resistant Lexan™ viewing window. RF Models are also available in versions with larger load frames built for testing masonry block in single block samples or two-block in prism.

How to Choose the Best Compression Machine for Your Lab

This blog post guides you through selecting the right machine and equipping it to be a versatile and efficient addition to your lab. Our five-step buying guide will help you select the specific concrete compression machine and adaptive accessories that will best suit your concrete compression testing needs.

Step 1: Know Your Sample Types and Strength Requirements

Test specifications, specimen sizes and types, and your desired degree of adaptability all dictate the best choice for a suitable concrete compression machine. Gilson's compression machines feature capacities from 250,000 to 650,000lbf (1112 to 2891kN) and are available in standard or automatic operation models. Machines with greater capacities are available by special order.

Here are some essential considerations to bear in mind:

Adaptability

Will you be testing only one sample type, such as cylinders, or do you want the capability also to test cubes, cores, prisms, and beams in a range of sizes? Optional accessories are available to adapt your compression machine for more than one testing application. Gilson compression machines maintain force and load rate accuracy at lower loads for reliable testing of shear or flexure specimens or smaller samples in compression.

Capacity

What is the compressive strength of the samples to be tested? Loading any compression machine to the upper limits of its capacity day after day shortens the service life of components, accessories, and even the steel frame itself. A good rule of thumb is to select a frame with a total capacity approximately 20% greater than the anticipated maximum loadings. So, a compression machine with a total capacity of 250,000lbf is ideal for testing 6x12in cylinders with expected compressive strengths up to about 7,000psi. To test concrete specimens with higher design strengths, consider specimens with smaller surface areas if permitted. The same 250,000lbf capacity machine can reliably test 4x8in cylinders with design strengths of up to 15,000psi.

Note: Use caution when testing very high-strength concrete. High-strength mixtures are often brittle and prone to explosive disintegration when they fail during compression testing. These failures cause hazards from flying fragments, and the shock may damage electronic and hydraulic systems. Ensure that the machine is equipped with protective fragment guard doors and other safety features. |

Size

What specimen sizes will you be testing? The inside dimensions of the frame, or "daylight opening," should be sufficient to accommodate the maximum specimen sizes with the required loading components and spacers while ensuring ease of handling. Compression machines are typically supplied ready to test 6x12in cylinder specimens using neoprene pad caps with steel retaining rings. The machines are quickly converted to test cylinders with sulfur mortar caps or 4x8in cylinders using only spacers or additional platens.

Masonry prisms can require a surprisingly large opening, especially if capped. Spacers in various sizes and thicknesses are available to adjust the opening size for each sample type.

Type of Test

What do the standard test methods say? What are the requirements? In addition to ASTM C39, other industry standards may apply to your specific testing applications. Some of the ASTM or AASHTO test methods easily performed with concrete compression machines outfitted with available accessories are listed below.

Features

What about hydraulics? Safety? Convenience? Features like two-stage hydraulic systems with quality valve controls and reliable electric motors are widely available on name-brand machines produced in the USA. Gilson compression machines offer designs to prevent over-extension of the hydraulic ram, a common and costly mistake, and pressure limit switches (optional on basic models) to prevent overloading of the frame. Fragment guard doors are standard equipment, and the motor and hydraulic system of automatic machines are integrated with the controller.

Step 2: Understanding Frame Capacity, Stiffness, and Deflection

According to the National Ready Mix Concrete Association (NRMCA), the compressive strength of concrete is "the most common performance measure used by the engineer in designing buildings and other structures." It's important to select a concrete compression machine that complies with ASTM C39 and other applicable ASTM and AASHTO standards. It should also adhere to rigidity recommendations in ACI 363.2R, which states the load frame should have a total capacity "at least 20% greater than the expected ultimate load of the cylinders."

A stiff load frame, both longitudinally and laterally, assures uniform specimen loading, reduces explosive failures, and generally has a longer service life. Explosive failures, especially with high-strength concrete samples, can produce shocks to the hydraulic and electronic systems, causing damage and loss of calibration.

Step 3: Operation and Data Collection

Decide on the best way to collect, save, and distribute your test data and results. If you only have a few cylinders to break now and then, a simple controller may be enough to help you organize and retain what you need most. However, if your lab has a heavy testing schedule, there are benefits of a system designed for production and efficiency that minimizes human error.

- Basic controllers feature a human-machine interface (HMI) that allows users to enter test data, view force, stress, and rate of load, and print or transfer test data. Live graphing data of load vs time or stress vs strain can be viewed during testing. Testing requires close, full-time attention from a human operator for the entire test cycle.

- Automatic controllers regulate the operation of the machine from start to finish for specified test methods, enhancing accuracy, repeatability, and efficiency. Data handling is optimized for secure sample ID, storage, and report generation. These controllers are also energy efficient, long lasting, and quiet.

Step 4: Increase Versatility with Adaptive Accessories

Once you have determined the best features, capacities, and capabilities, choose the specific accessories for the selected machine to optimize them for your applications. Concrete strength testing accessories enhance the functionality and effectiveness of each compression machine. These accessories allow testing of flexural beams, masonry prisms, different cylinder sizes, cubes, and cylinder splitting for tensile strength.

Consider not just the accessories, but what it will take to change the machine over to accommodate them. Upper platens to test 6in cubes or masonry block prisms are heavy and difficult to install unless you use an optional carrier bracket. Locking stems make switching platens quick and easy, but threaded draw rods used with the right spacers allow easy adjustments to the daylight opening.

Step 5: Pick the Compression Testing Machine that Best Meets Your Needs

Specific characteristics of Gilson's Concrete Compression Machines are shown below. Models are supplied ready for testing 6x12in concrete cylinders with user-supplied unbonded neoprene capping pads and steel retainers. Masonry block machines are supplied ready for testing their respective sample types. All machines can be outfitted with a full range of optional accessories to test flexural beams, cubes, tensile splitting samples, and other configurations of cylinders and cores. Contact Gilson for custom compression testing machines with higher capacities, special control consoles, and multiple loading frames.

| Model | Total Capacity, lbf (kN) | Maximum psi (kPa), 6x12 Cylinder | Daylight Openings, WxH, in | Overall Dimensions, WxDxH, in | Standard Test Methods (Accessories Sold Separately) | ||

|---|---|---|---|---|---|---|---|

| Maximum | With Platens | ASTM | AASHTO | ||||

| BC-250 | 250,000 (1,112) | 7,000 (48,265) | 9.25x19.375 | 9.35x13.375 | 30x17x58 | C39, C78, C109, C293, C469, C496, C1019, C1609 | T 22, T 97, T 106, T 177, T 198 |

| BC-325 | 325,000 (1,446) | 9,200 (63,434) | 9.5x19.25 | 9.5x14.25 | 33x17x58 | ||

| BC-450 | 450,000 (2,016) | 12,700 (87,567) | 9.5x19.125 | 9.25x14.25 | 34x24x60 | ||

| Model1, 2 | Total Capacity, lbf (kN) | Maximum psi (kPa), 6x12 Cylinder | Daylight Openings, WxH, in | Overall Dimensions, WxDxH, in | Standard Test Methods (Accessories Sold Separately) | ||

|---|---|---|---|---|---|---|---|

| Maximum | With Platens | ASTM | AASHTO | ||||

| AC-250 | 250,000 (1,112) | 7,000 (48,265) | 9.25x19.375 | 9.25x14.625 | 30x17x58 | C39, C78, C109, C293, C469, C496, C1019, C1609 | T 22, T 97, T 106, T 177, T 198 |

| AC-325 | 325,000 (1,446) | 9,200 (63,434) | 9.5x19.25 | 9.5x14.25 | 33x17x58 | ||

| AC-450 | 450,000 (2,016) | 12,700 (87,567) | 9.5x19.125 | 9.5x15.125 | 34x24x60 | ||

| AC-650 | 650,000 (2,891) | 18,400 (128,868) | 11x19.125 | 9.5x15.125 | 35x24x62 | ||

| AC-250M | 250,000 (1,112) | 7,000 (48,265) | 9.25x19.625 | 9.25x14.625 | 30x17x58 | ||

| AC-325M | 325,000 (1,446) | 9,200 (63,434) | 9.5x19.25 | 9.5x14.25 | 33x17x58 | ||

| AC-450M | 450,000 (2,002) | 12,700 (87,567) | 9.5x19.125 | 9.5x15.125 | 34x24x60 | ||

| AC-650M | 650,000 (2,891) | 18,400 (128,868) | 11x19.125 | 9.5x15.125 | 35x24x62 | ||

| AC-250MR | 250,000 (1,112) | 7,000 (48,265) | 9.25x19.625 | 9.25x14.625 | 30x17x58 | ||

| AC-325MR | 325,000 (1,446) | 9,200 (63,434) | 9.5x19.25 | 9.5x14.25 | 33x17x58 | ||

| AC-450MR | 450,000 (2,002) | 12,700 (87,567) | 9.5x19.125 | 9.5x15.125 | 34x24x60 | ||

| AC-650MR | 650,000 (2,891) | 18,400 (128,868) | 11x19.125 | 9.5x15.125 | 35x24x62 | ||

¹”M” models are factory-configured for ASTM C469 modulus of elasticity (MOE) testing using optional accessories.

²”MR” models are factory-configured for ASTM C469 modulus of elasticity (MOE) and Poisson’s ratio testing using optional accessories.

| Model1, 2 | Total Capacity, lbf (kN) | Maximum psi (kPa), 6x12 Cylinder | Daylight Openings, WxH, in | Overall Dimensions, WxDxH, in | Standard Test Methods (Accessories Sold Separately) | ||

|---|---|---|---|---|---|---|---|

| Maximum | With Platens | ASTM | AASHTO | ||||

| AC-300 | 300,000 (1,334) | 8,500 (58,608) | 10x19 | 10x14.5 | 32x19x57 | C39, C78, C109, C293, C469, C496, C1019, C1609 | T 22, T 97, T 106, T 177, T 198 |

| AC-400 | 400,000 (1,779) | 11,300 (77,914) | 11x19 | 11x14.5 | 33x19x61 | ||

| AC-500 | 500,000 (2,224) | 14,100 (97,220) | 12x19 | 12x14.5 | 35x20x60 | ||

| AC-300M | 300,000 (1,334) | 8,500 (58,608) | 10x19 | 10x14.5 | 32x19x57 | ||

| AC-400M | 400,000 (1,779) | 11,300 (77,914) | 11x19 | 11x14.5 | 33x19x61 | ||

| AC-500M | 500,000 (2,224) | 14,100 (97,220) | 12x19 | 12x14.5 | 35x20x60 | ||

| AC-300MR | 300,000 (1,334) | 8,500 (58,608) | 10x19 | 10x14.5 | 32x19x57 | ||

| AC-400MR | 400,000 (1,779) | 11,300 (77,914) | 11x19 | 11x14.5 | 33x19x61 | ||

| AC-500MR | 500,000 (2,224) | 14,100 (97,220) | 12x19 | 12x14.5 | 35x20x60 | ||

¹”M” models are factory-configured for ASTM C469 modulus of elasticity (MOE) testing using optional accessories.

²”MR” models are factory-configured for ASTM C469 modulus of elasticity (MOE) and Poisson’s ratio testing using optional accessories.

| Model | Total Capacity, lbf (kN) | Masonry Block Samples | Daylight Openings, WxH, in | Overall Dimensions, WxDxH, in | Standard Test Methods (Accessories Sold Separately) | ||

|---|---|---|---|---|---|---|---|

| Maximum | With Platens | ASTM | AASHTO | ||||

| AC-401 | 450,000 (2,002) | 8 or 12in Single Blocks | 14x19 | 14x14.5 | 34x22x62 | C39, C78, C109, C140, C293, C469, C496, C1019, C1314, C1609 | T 22, T 97, T 106, T 177, T 198 |

| AC-502 | 500,000 (2,224) | 8 or 12in Single or 2-Block Prisms | 14x23.875 | 14x19.375 | 35x23x66 | ||

We hope the information in this guide helps you select the compression testing machine that gets the job done the first time, adheres to industry standards and recommendations, and maintains quality control and quality assurance protocols. Contact our technical support professionals today for additional information about concrete compression testing machines.

References:

ASTM

- C39, Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens

- C78, Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading)

- C109, Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens)

- C140, Standard Test Methods for Sampling and Testing Concrete Masonry Units and Related Units

- C293, Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading)

- C469, Standard Test Method for Static Modulus of Elasticity and Poisson's Ratio of Concrete in Compression

- C496, Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens

- C1019, Standard Test Method for Sampling and Testing Grout for Masonry

- C1314, Standard Test Method for Compressive Strength of Masonry Prisms

- C1609, Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading)

- E4, Standard Practices for Force Calibration and Verification of Testing Machines

AASHTO

- T 22, Standard Method of Test for Compressive Strength of Cylindrical Concrete Specimens

- T 97, Standard Method of Test for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading)

- T 106, Standard Method of Test for Compressive Strength of Hydraulic Cement Mortar (Using 50-mm or 2-in. Cube Specimens)

- T 177, Standard Method of Test for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading)

- T 198, Standard Method of Test for Splitting Tensile Strength of Cylindrical Concrete Specimens

American Concrete Institute (ACI)

- 363.2R Guide to Quality Control and Testing of High-Strength Concrete

British Standards

- BS 1881, Testing Concrete - Methods for Analysis of Hardened Concrete