- Log in

- Favorites List

-

Shopping Cart

You have no items in your shopping cart.

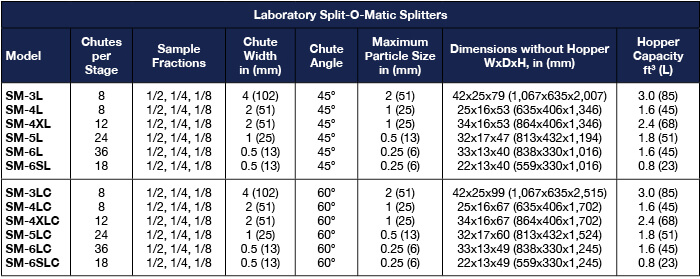

Laboratory Split-O-Matic Splitters

Laboratory Split-O-Matic Splitters quickly and accurately reduce large samples of aggregates, ores, coal, and other materials through its exclusive three-stage design. A selection lever sets internal sample fraction positions, directing the selected fraction to the sample pan and the balance to the reject pan. V-bottom chutes precisely align material flow for more accurate divisions.

2.4ft³ Hopper Laboratory Split-O-Matic with 12 Chutes per Stage

1.8ft³ Hopper Laboratory Split-O-Matic with 24 Chutes per Stage

1.6ft³ Hopper Laboratory Split-O-Matic with 36 Chutes per Stage

0.8ft³ Hopper Laboratory Split-O-Matic with 18 Chutes per Stage

Click the table to enlarge, print, or download.

Laboratory Splitters are well-suited for aggregates, sand, gravel, ores, coal, coke, or other free-flowing granular materials up to 2in (51mm) topsize. These units have a higher capacity for processing bulk samples of granular materials into small fractions with a single pass for efficient preparation of test specimens.

The splitters are constructed of heavy, welded steel with a painted and baked finish. Sample hoppers have a gate-release mechanism for greater control of sample dividing. Front panel doors latch shut for superior dust control and open wide for easy cleaning. Sample pans are included and are size-matched to hopper capacity. The bottom flange is suitable for anchored or freestanding lab use. Standard models feature three stages of 45° chute slopes, ideal for most materials. Steeper 60° chute slope models are recommended for low specific gravity materials such as coal, coke or materials with a large fraction of fines. The 60° Laboratory Splitters are approximately 20% taller, slightly heavier, and are ordered by adding a “C” suffix to model numbers.

There are many models to choose from, offering varying choices in chutes per stage, sample fractions, chute width, chute slope, and maximum particle size to suit your application. For best results, choose a splitter with a chute width at least twice that of the material’s topsize to avoid bridging over chute openings. For coal or coke, or materials with oblong pieces, 3 to 4 times topsize is recommended. Every Laboratory Splitter can be custom-ordered with special larger hopper and sample pans if needed. Custom models may also be ordered with four or more chute stages for sample fractions smaller than .125mm.

For more information on Laboratory Split-O-Matic Splitters, here are our related blogs: