High decibel levels can potentially be a dangerous element in your materials testing lab. In part two of our special series on workplace safety, you’ll discover some of the best ways to reduce noise levels during testing.

- Log in

- Favorites List

-

Shopping Cart

You have no items in your shopping cart.

Blog posts tagged with 'Sieving'

Have questions about your materials testing equipment? We have the answers to these questions and much more right here! Check back monthly for long-form blog posts, how-to guides and infographics. We’ll address industry insights, the operation and maintenance of specific equipment, and our product line recommendations, all designed to better serve you.

Bookmark this page, add it to your RSS reader, or subscribe to our newsletter, so you never miss a hot topic.

In part one of our special series on workplace safety, we take a look at how advances in materials testing equipment are minimizing potentially harmful exposure to dust in the lab.

Sieving for particle size distribution is the primary test requested for construction aggregate samples. Whether field samples are being tested to evaluate a new aggregate source or just coming in as part of day-to-day quality control of production, particle size distribution is a primary consideration. If processing and sieving is not handled efficiently, it creates a backlog.

Reference materials for test sieves are used to evaluate and help ensure continued quality performance of sieves in compliance with ASTM or ISO standards. Sieve Verification Services provide further assurance of compliance through laboratory optical or microscopic examination.

In part 3 of this three-part series, we’ll cover the procedure for effective particle size distribution of coarse aggregates, useful equipment and testing tips.

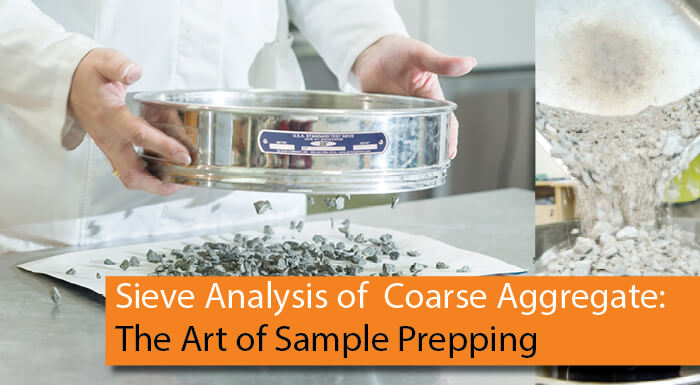

In part 2 of this three-part series, we’ll outline a sieve analysis of coarse aggregate including proper preparation of bulk field samples for lab testing and necessary equipment and tips.

When dry sieving isn’t sufficient for producing an acceptable degree of separation between individual fractions of a sample, it’s time to try wet sieving. This blog post covers the importance of wet sieving, when it is best used, and recommended equipment for various procedures.

In Part 1 of this thee-part series, we’ll cover sieve analysis of coarse aggregate, beginning from gathering samples at a job site, including tips and necessary equipment.

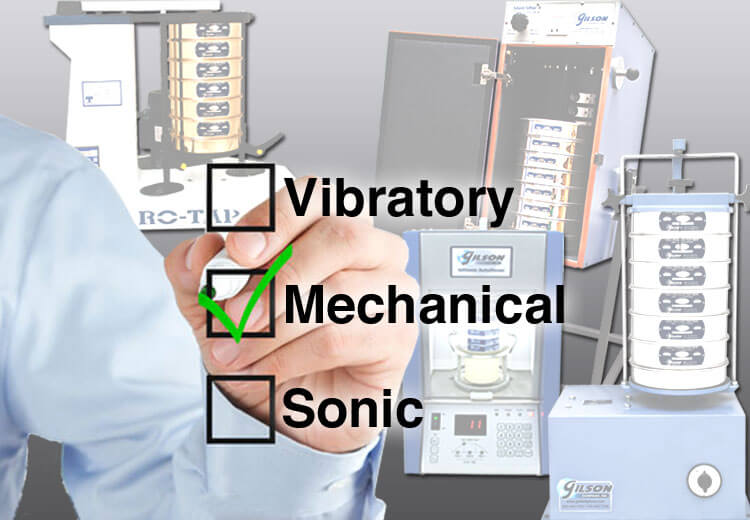

Proper sieve shaker selection saves a considerable amount of time in the lab while improving accuracy and efficiency. Read our post about selecting the machine most suitable for your purposes.

If you want to get optimal use out of your test sieves, you need to take the proper steps when it comes to storing and cleaning them. We’ve outlined a list of do’s and don’ts to follow this Spring so you can make your sieves last longer and retain their accuracy.

- 2026

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015