What is the Purpose of the Sand Equivalent Test?

Fines and dust in asphalt and concrete aggregates have always been a problem. Whether naturally occurring or resulting from degradation during handling and transport, undesirable or unknown amounts of fines can impact the performance and cost of composite materials.

Although controlled amounts of fines and dust can improve some characteristics of asphalt or concrete mixes, too much negatively affects the behaviors of the materials. Excessive fines increase the total surface area of solids in concrete and reduce workability while increasing water demand. In asphalt, high fines contribute to a loss of adhesion between asphalt binder and aggregate, and more binder is required.

In 1953, the sand equivalent test was presented in the Highway Research Board Proceedings, by Francis N. Hveem. (pronounced “veem”) a materials and research engineer with the California Division of Highways.

Photo Credit: aashtoresource.org

The test measures the proportions of clay-like fines in granular soils and aggregates and can be run in as little as 40 minutes. The procedure can be performed in a fully equipped laboratory or at a remote field outpost for on-the-spot quality control checks.

The legendary Hveem also originated other significant test methods and equipment, including the Hveem asphalt mix design method, Hveem stabilometer, the cohesiometer, and the moisture susceptibility test for asphalt.

The Sand Equivalent Test Method

As a standard test method described in ASTM D2419 and AASHTO T 176, the sand equivalent test is now widely used to measure the relative proportions of undesirable fines in aggregates and granular soils.

The procedure may not employ precision instrumentation, but it does require close attention to detail and procedures to produce accurate and repeatable results. This test is also needed to evaluate aggregate samples after performing the Aggregate Durability Index test (ASTM D3744/AASHTO T 210).

The Sand Equivalent Test Procedure

- A prepared sample of fine aggregate is added to a working solution of calcium chloride and glycerin in a unique graduated cylinder.

- The cylinder is agitated in a prescribed manner, either manually or by a mechanical shaking device.

- After agitation, a metal irrigation tube is manually worked into the sample with a stabbing action, introducing more solution and flushing the finer particles into suspension.

- The fines then settle to the top of the column of solids.

- After a sedimentation period, the level of the top of the clay suspension is observed and recorded as the clay reading.

- A weighted-foot assembly is carefully lowered into the cylinder to rest on the sample to determine the sand reading.

- The value can now be determined.

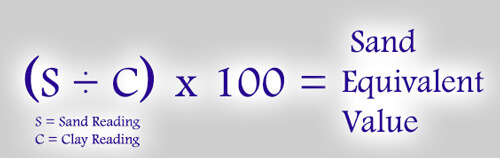

The Sand Equivalent Value

The value is the ratio of the sand reading divided by the clay reading times 100.

Sand Equivalent Test Apparatus

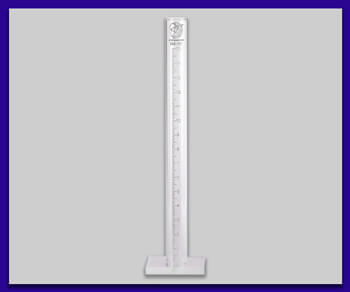

Graduated Cylinders

Instead of volumetric divisions, the clear acrylic cylindersused for this test have graduations every 0.1in and a sturdy plastic base. During manual or mechanical agitation, a No. 7 rubber stopper seals the top of the cylinder.

Siphon assembly

The siphon controls the transfer of working solution into the graduated cylinder for irrigation of the sample. This assembly consists of metal and latex tubing with a pinch clamp and a stopper fitted into the working solution container. The siphon effect is initiated by blowing into a short section of the tube.

Irrigator Tube

The irrigator is attached to the latex tubing of the siphon assembly and flushes a stream of working solution into the sample during the irrigation procedure to bring the fine particles into solution.

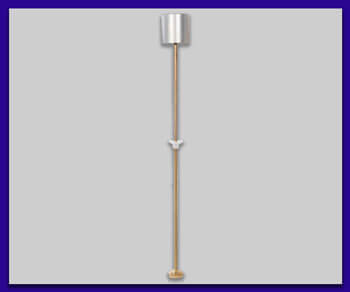

Weighted Foot Assembly

The assembly is immersed into the graduated cylinder to determine the sand reading of the test sample. The foot sinks through the upper portion of clay-sized particles and comes to rest on top of the coarser sand fraction. Measurements taken from a marker positioned 10 inches above the foot are subtracted to determine the sand reading.

Measuring Tin

The measuring tin serves dual purposes for measuring out stock solution concentrate when making up the working solution, and as a volumetric measure when preparing the test specimen.

Sand Equivalent Shakers

Motorized or hand-crank shakers add efficiency, accuracy, and repeatability to the testing process. Manual agitation is acceptable, but the specified reciprocating action can be difficult and tiring to perform correctly. Economy shakers are easy to set up and use anywhere. A motorized shaker removes any operator error, optimizes accuracy, and produces the most consistent results.

Sample Splitters

Splitters provide the most accurate representative samples when preparing test specimens. The test method allows some manual sample dividing methods, but a mechanical splitter has a clear advantage in producing a representative sample.

Sand Equivalent Solutions:

- Stock Solution is a concentrated mixture of calcium chloride in glycerin and is added to distilled water when preparing the working solution used in the test method. One gallon (3.8L) of the stock solution makes over 44 gallons of working solution. Because the blend is an ideal medium for fungal growth, a bioicide such as formaldehyde or glutaraldehyde is generally added to the mixture unless the storage time of the liquid will be very brief. Stock solution can be mixed “from scratch” using reagents in proportions noted in the test method, but it is nearly always more efficient and cost-effective to purchase the prepared solution from a supplier. The actual useful life of the stock solution varies with storage conditions but will generally last three months or more. If sand equivalent testing is not performed often, purchasing smaller quantities of stock solution is less expensive. Discard the product if slimy growth forms in the container.

- Working Solution, or flocculating solution, is prepared from the concentrated stock solution by mixing 85ml of the stock solution into 1.0gal (3.8L) of distilled or demineralized water. When irrigating the sand equivalent sample, the working solution container must be positioned 36in (90cm) above the work surface. As with the stock solution, the purity of the working solution needs to be monitored over time and discarded if fungal growth occurs.

Note: Oven-drying and weighing are not mandatory to carry out the test, so laboratory ovens and lab balances or scales are not strictly required.

We hope this blog post has helped you understand the sand equivalent test method a little more. Gilson offers a Sand Equivalent Test Set which includes components listed or visit the Sand Equivalent Test Equipment page for more information regarding the equipment.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)