Why the Soundness Test of Aggregate is Performed

Construction aggregates resistant to degradation from freeze-thaw and weathering actions are likely to perform better over the long term in concrete and asphalt mixes for paving applications. These materials typically feature good overall durability and have low void ratios and low absorption rates, as noted in a previous blog Aggregate Properties You Need To Know: Strength and Durability.

Significant quality variability in aggregates sourced from natural deposits and formations calls for care in the production and selection of materials, particularly in areas subject to freeze-thaw cycles. Historical service records of the specific aggregate type are a valuable resource. Lacking these, sulfate soundness testing outlined in ASTM C88 or AASHTO T 104 provides a valid preliminary estimate of freeze-thaw and weathering resistance.

What is Sulfate Soundness?

Procedures for this popular test method are straightforward, and the equipment required is neither sophisticated nor expensive. Meaningful results are produced in a reasonable time compared to other methods.

The statistical precision of this test method is not high, and there will be variation between outcomes using the sodium sulfate or magnesium sulfate solutions. Test results should be considered a preliminary estimate of aggregate suitability and not used for outright rejection of the source. Close control over testing elements like temperature, timing, types of containers, and sieving methods will minimize variability.

When needed, results can be confirmed with other tests. AASHTO T 103 uses similar procedures but requires many more cycles in extreme freezing and thawing temperatures. Sodium chloride, alcohol, or water immersion solutions are used instead of sulfates. ASTM C666 tests samples of concrete mixes in air or water using freeze-thaw cycles.

Summary of the Sulfate Soundness Test

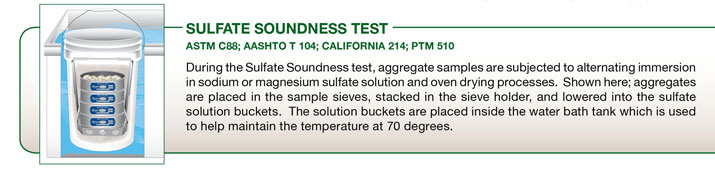

Separated size fractions of the fine and coarse aggregate sample are immersed for timed cycles into a sodium sulfate (Na2SO4) or magnesium sulfate (MgSO4) solution, then oven-dried and immersed again. Crystals of the salt solution grow in voids and fissures of the aggregate particles during the immersion and drying cycles, simulating the expansive force of ice crystals and causing degradation of the particles.

After completion of the test cycles and a final washing, each size fraction is again sieved and weighed to determine the percentage of mass lost by degradation during the process. A qualitative examination of the coarse aggregate classifies the degree of damage sustained by the particles. Test results between the sodium and magnesium solutions do not correlate.

Sulfate Solution Preparation

Chemicals used for the soundness test of aggregates include Sodium sulfate or magnesium sulfate USP grade salts. These are widely available from chemical suppliers in either anhydrous or crystalline form. To prepare the immersion fluid, stir the chemical salts in 25° to 30°C (77° to 86°F) water until the mixture is saturated and some solids precipitate back out of solution. About 350g of anhydrous or 750g of crystalline chemical per liter of water is usually sufficient. The solution volume must be at least five times the volume of the solids of the samples to be immersed at one time.

The prepared mixture must be covered to reduce evaporation, frequently stirred to break up the salt cake, and maintained at 70±2°F (21±1°C) for 48 hours before use. In some cases, like a temperature-controlled laboratory, the temperature limitations are easily met. Other situations require that the solution be artificially heated or cooled to maintain compliance. At the time of use, caked material must be broken up and stirred back into solution. The specific gravity of the solution must be between 1.151 and 1.174 for sodium sulfate or between 1.295 and 1.308 for magnesium sulfate.

Aggregate Sample Preparation

Selection and preparation of the aggregate sample fractions must strictly follow the procedures in the ASTM or AASHTO standard test methods. The bulk samples are thoroughly washed over specified sieves and oven-dried before separating into the specified size fractions.

- For fine aggregates, test portions consist of 100g of material from each specified sieve fraction.

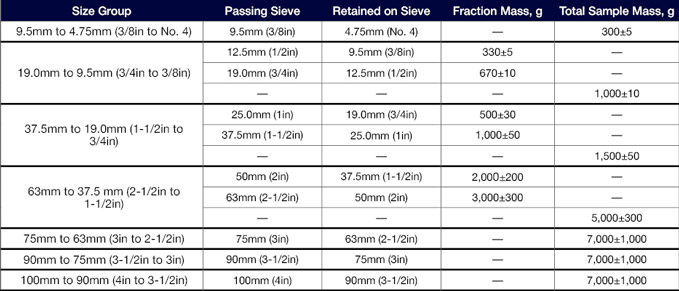

- Coarse aggregate specimens consist of particle size groups and may combine specified amounts of two size fractions to make up their total mass.

Performing the Sulfate Soundness Test

Record the initial mass of each fraction and immerse the samples in the prepared solution for 16 to 18 hours. The containers are covered to prevent evaporation or contamination, and temperature is maintained and recorded at 70±2°F (21±1°C). At the end of each immersion cycle, the sample is drained, oven-dried to a constant mass, and cooled to room temperature before immersion for the next cycle.

Each cycle takes about one day, and five cycles are typically required. Once the cycles are complete, the sample is washed with a reverse flow of warm water. The final wash water is tested with a barium chloride solution to ensure the sample is entirely free of the sulfate solution. The barium solution will turn cloudy if sulfates are present.

Each fraction is dried and sieved again, and the percent loss from the initial gradation is calculated. A qualitative examination is also performed on fractions coarser than 3/4in (19.0mm). Particles from these fractions are grouped according to the type of degradation like splitting, flaking, cracking, disintegration, etc. Particles from each group are counted and recorded.

Sulfate Soundness Testing Equipment

Gilson’s selection of magnesium and sodium sulfate soundness test equipment optimizes value, efficiency, and convenience. Components are purchased as needed.

- ASTM E11 Test Sieves are required for all particle sizing and sorting operations of aggregate soundness tests.

- Sulfate Soundness Test Sieves are a favored method of handling soundness samples for immersion and washing. The sieves allow free flow of sulfate solution with no loss of sample material and nest for easy handling. Test specimens are contained by 8in (203mm) diameter full-height or half-height sieves, and sieve frames with no mesh accommodate large-volume samples.

- Sample Sieve Holders add even more convenience to soundness testing. The stainless steel frame holds multiple Soundness Sieves for immersion and washing and features a folding and locking handle.

- Platinum RTD Datalogging Thermometers comply with test method requirements for a precision data logging thermometer. The temperature range is –130° to 221°F (–90° to 105°C) with 0.01º resolution and accuracy of ±0.2°C.

- Hydrometers for sodium sulfate or magnesium sulfate measure the specific gravity of the immersion solution to ±0.001.

- Solution Bucket holds prepared sulfate solution for the immersion of aggregate samples in Sulfate Soundness Sieves. Each bucket will accommodate one Sample Sieve Holder with a stack of sieves.

- Water Bath Tank controls the temperature of the sulfate solution for up to four Solution Buckets immersed in the tank. Circulation inlets and drain fittings allow circulation of warm or cool tap water to regulate solution temperature. Cover included.

- Washing Bucket makes final washing of soundness samples easy. Sieve Holders with Soundness Sieves are placed inside, and warm water circulates up through the bottom inlet and out through a top overflow to flush away the sulfate solution after test cycles are complete.

We hope this blog about the sodium and magnesium sulfate soundness test for construction aggregates has answered your questions.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)