FHWA Mobile Concrete Lab Background and Objectives

Beginning in the last two to three decades of the 20th century, federally funded ventures like the Strategic Highway Research Program (SHRP) and Intermodal Surface Transportation Efficiency Act (ISTEA) began driving research and innovation in civil infrastructure, paving technology, and materials. Researchers have made great strides in developing and understanding concrete materials, mix designs, testing, and evaluation that set the stage for more durable and longer-lasting pavements and structures.

Despite the exciting possibilities, transferring this newfound technology into everyday engineering and construction practice was proving to be complicated. Industry inertia and resistance to change was an issue, but what was really needed was an informational platform to demonstrate, educate, assist, and participate in the implementation of new tests and testing equipment.

The Show About the Road Goes on the Road

The Federal Highway Administration (FHWA) helped bridge the technology gap by introducing the Mobile Concrete Laboratory (MCL). The full-size semi-trailer outfitted as a rolling testing lab and functional education facility, showcased the latest tests and testing equipment advances. Roaming as far as Alaska, Hawaii, and Puerto Rico, the demonstration trailer became the flagship for advancing both new and proven methodologies in concrete testing. Now updated with a new trailer, the renamed Mobile Concrete Technology Center (MCTC) continues to crisscross the United States on its mission of technology deployment for our concrete industry.

More than an Exhibition

At the heart of the MCTC is the experienced FHWA engineering and technical staff responsible for its operation. The team in the trailer has a deep background in concrete mix design, testing, and pavement engineering. The entire MCTC staff at FHWA is focused on providing information, guidance, and services that help all stakeholders produce durable and sustainable concrete infrastructure products.

- MCTC staff provides in-person or virtual seminars and workshops, training users in new testing equipment and methodologies, mix design approaches, and performance-related specifications.

- "One-Pager" technical bulletins cover concrete materials, mix design, and testing topics.

- Peer-reviewed papers and Journal articles discuss a variety of subjects like quality assurance, concrete properties and performance, sustainability, coefficient of thermal expansion testing, and more.

- A loan program allows users the trial use of selected testing devices to ensure compatibility with their application before purchasing.

- The FHWA trailer can operate as a field lab on real-world infrastructure projects, assisting state highway departments and other local agencies with on-site concrete testing and equipment training.

The Newest Equipment: Find it at Gilson

During a scheduled visit of the MCTC to the Ohio State University School of Engineering in Columbus, Gilson technical staff had an opportunity to chat with MCTC engineers and technicians, tour the trailer, and look over some of the equipment on hand. Many items featured in the trailer are available directly from Gilson.

The Concrete Phoenix System is a new way to accurately measure fresh concrete's water-to-cementitious material ratio (w/cm) in the lab or field. A concrete sample is consolidated in a special mold for unit weight information, then transferred to a pan and heated in the high-temperature chamber of the Phoenix furnace for about 15 minutes. The w/cm ratio is calculated on a smartphone app using the total weight of water lost in heating and the actual batch weights of the concrete mix.

The concrete Super Air Meter (SAM) determines fresh concrete's air void spacing factor. This property provides more reliable predictions of long-term durability than total air content alone. A matrix of small, well-dispersed air bubbles in the mortar is ideal to resist damage from the forces of freeze-thaw cycles. The SAM functions in much the same way as a conventional concrete pressure air meter but identifies the air void spacing factor by using sequential and increasingly higher pressurization cycles. This meter meets all the requirements of the new AASHTO T 395 test method for characterizing the air void system in fresh concrete. It can also be used as a conventional air meter meeting ASTM C231/AASHTO T 152 standards for air content by the pressure method.

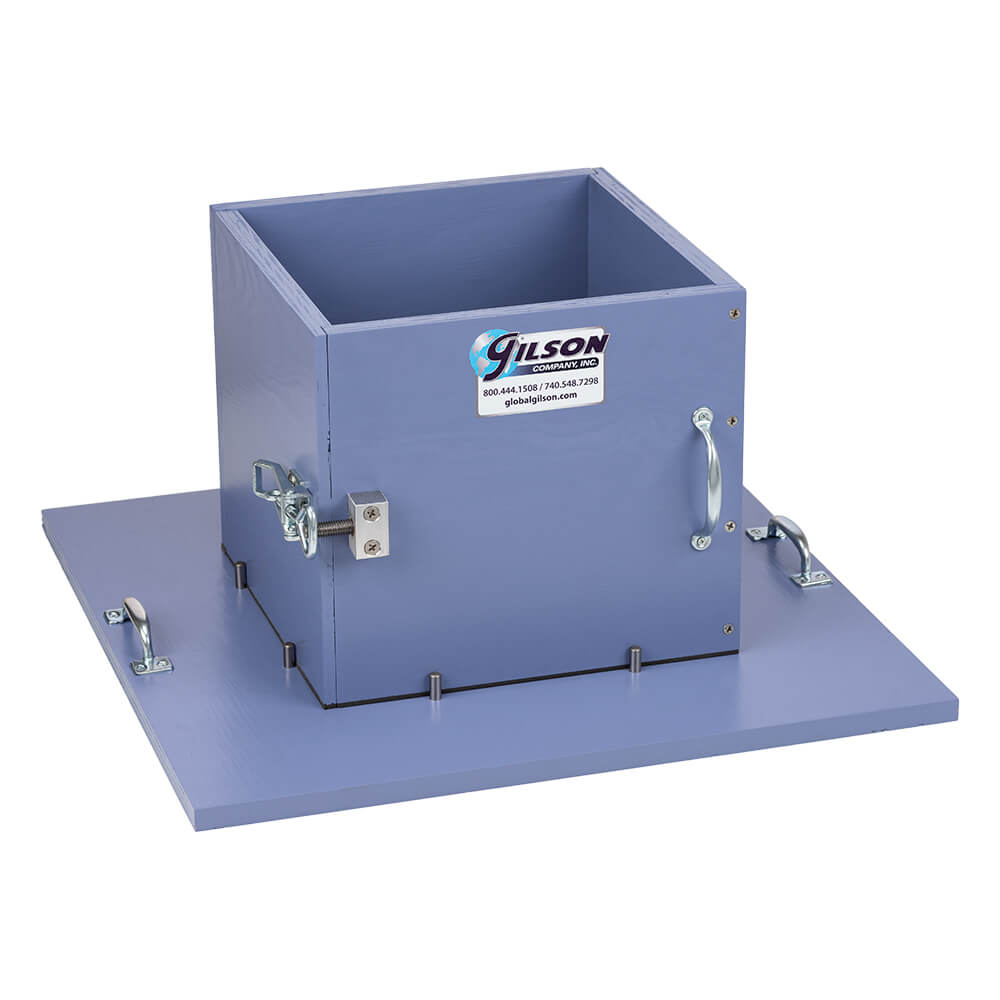

The Box Test Device tests the stability of fresh concrete placed for slip-form paving operations. A good quality concrete paving mix must hold its shape with minimal surface voids after consolidation and placement through the paver. When secured to the base plate, the two interlocking halves of the Box Test Device form a 12in (305mm) square. Following the procedure in AASHTO test method T 396, fresh concrete is placed in the box and consolidated with a vibrator. The sides are removed, and the sample displacement at the edges is measured and recorded.

The surface electrical resistivity of concrete correlates closely to its permeability, chloride diffusion rate, and the potential for chloride-induced corrosion of reinforcing steel. The Resipod Concrete Resistivity Meter meets the requirements of AASHTO T 358 and is fast, accurate, and easy to use. The hand-held meter is an excellent predictor of the long-term durability of concrete and an economical alternative to the time-consuming ASTM C1202 Rapid Chloride Permeability test. Recording a surface resistivity reading is as simple as pressing the four-probe Wenner array against the saturated surface of a conventional test cylinder in the lab or the surface of a structure in the field.

The Coefficient of Thermal Expansion Test System (CTE) predicts thermally induced expansion and contraction movements in concrete pavement. Concrete specimens mounted in a measuring frame are immersed in a water bath, and precise length change measurements are recorded at specified temperatures over a range of 10°–50°C (50°–122°F). Research from the NCHRP 1-37A program found that thermal movements significantly impacted pavement performance and integrated CTE values into the FHWA Pavement Design Guide.

Alternatives in Equipment Selection

When concrete test methods or techniques are in the spotlight in the MCTC, the testing equipment is often available from various manufacturers. Even though it may vary in some details, equipment meeting the apparatus requirements of the standard still produces good results.

Concrete strength testing performed on Automatic Compression Machines brings a new level of accuracy, repeatability, and efficiency to everyday ASTM C39 and C78 strength determinations on concrete specimens. Minimal operator input reduces the risk of error and saves labor costs for sample preparation, positioning, and preloading during the test cycle. Automated data collection, storage, and reporting features enhance models with built-in instrumentation for ASTM C469 determinations of elastic modulus and Poisson's ratio.

A Pull-Off Tester measures the tensile strength of bonded layers. The test provides valuable input to assess materials and methods to create durable, long-lasting pavement overlays and repairs. Following ASTM standard test method C1583, a circular cut is made with a coring bit to a depth of 10mm (0.5in) below the overlay interface. A steel disk is bonded to the surface with an epoxy compound, and the Pull-Off Tester is coupled to the steel disk. A load is applied with the tester until failure occurs. The total load, location of the failure plane, and type of failure are recorded.

MCTC: The Road to Better Pavements

The Mobile Concrete Technology Center promotes the diffusion, understanding, and applied use of new ways and better equipment to measure concrete performance. More importantly, it helps technicians master new methods and equipment and assists agencies in implementing the technology into codes and regulatory language where it makes the most significant impact. Without the operation of the MCTC, many vital advancements in concrete technology would languish in research laboratories and libraries.

We hope this article has helped you learn more about the FHWA Mobile Concrete Technology Center and its objectives. See the references below for more detailed information. For questions about test methods and testing equipment, please contact the testing experts at Gilson.

References & Links

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)