Laboratory Oven Principle

A good laboratory oven will last for many years of heavy use day after day, so it’s worth putting a lot of thought into selecting the best oven for your needs. This blog post lays out some of the most important features to consider when you’re looking for an oven for aggregate, soils, concrete or asphalt testing.

Testing Applications

Construction materials test applications use laboratory ovens to dry materials at controlled temperatures and to heat asphalt materials for handling and testing. It is important to follow test protocol when heating aggregates, soils, and asphalt and avoid high temperatures that may alter their properties. These ovens are used by other industries for applications such as heat-treating, annealing, and conditioning of metals and other materials.

Temperature Range

When matching a lab oven to your applications, maximum temperature ratings are a primary consideration. You obviously need an oven with a maximum temperature at or a bit above the highest temperature called for in your test methods. But models with higher temperature ranges may not always deliver the optimum stability and uniformity performance you need at lower temperatures. In addition, these ovens may use costlier components and can be more expensive to operate.

Many oven models also list a minimum operating temperature. This the lowest temperature that the oven will perform to the stated specifications. Minimum temperatures come into play when looking for an oven to test a variety of materials using different test methods.

Types of Convection Ovens

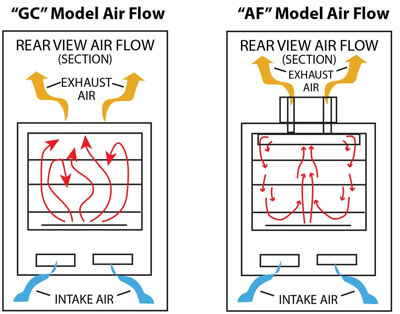

Heat is distributed throughout a laboratory oven’s chamber either by gravity convection or mechanical draft (forced draft) to heat the contents.

- Gravity ovens rely on temperature and density differences in the heated air for circulation in the chamber. This natural circulation can result in reduced levels of temperature stability and uniformity and occasional dead spots in the chamber. On the other hand, gravity convection ovens are ideal for simple drying applications or in cases where strong air currents may displace lightweight sample materials. They are often more economical to purchase and operate.

- Forced-air ovens have powered blowers that actively distribute air through special baffles in the chamber to produce even heating. Applications with multiple samples, higher moisture contents, and a required level of accuracy or uniformity will benefit from forced-air convection. Review test methods when deciding on an oven, many ASTM and AASHTO standards require a forced draft design.

Gravity (GC) and Forced Air (AC) Convection Examples

Chamber Selection

Chamber volume and dimensions are important factors to consider. The chamber needs to accommodate the size and shape of your samples, and you should think about the number of samples you would need to load in at a given time. If you select a chamber size based on a number that is too small, your workflow is hampered. A chamber that is too large means wasted space in your lab and higher operating costs to heat the unused chamber area. Externally, the oven needs to fit available floor space and ceiling clearances, and you must be able to move it in through available door openings. Most oven chambers are designed to accept additional shelves and to reposition existing shelves.

Uniformity & Stability

Uniformity in a lab oven is a measure of the consistency of the temperature at various points in the chamber. Cold or hot spots affect overall accuracy and may affect test results. All reputable oven manufacturers will indicate uniformity ratings of their laboratory models and some industrial models. Stability is the temperature range over and under the setpoint maintained in the oven by the thermostat or controller.

Energy Requirements

You should know the capacity and configuration of the electrical supply in your laboratory and the power requirements of the oven before purchasing. You may need to plan for electrical upgrades or modifications before installation. For some ovens, the amperage draw may be increased over the stated specifications during the start-up period. Gas-fired ovens may also be an option when large capacity chambers or continuous operations are anticipated, and when reduced uniformity can be tolerated.

Ventilation

If fumes from heated samples will be undesirable or hazardous in the laboratory, the oven’s exhaust must be vented to the outside. In some cases, the oven can be positioned under a fume hood with adequate capacity, and many ovens have options for direct forced-air exhaust through built-in ports. Some models include options for explosion-proof motors, required when materials or fumes are particularly volatile. Samples with high moisture content may also require ventilation for adequate drying performance. Safe and effective ventilation may require the services of an HVAC professional to design and install an optimal system.

Recovery Time

Opening the oven door frequently to add or remove samples puts an additional load on the system as it tries to make up lost heat. A short temperature recovery time is a desirable performance feature, but it does require additional energy. If your specifications call for a high level of uniformity and accuracy, shorter recovery time will be important to you. Otherwise, heat loss can be controlled satisfactorily by limiting door opening frequency and keeping an adequate sample load in the chamber.

Materials

Many laboratory ovens feature stainless steel interiors and shelf construction to resist corrosion and deterioration. If your materials are not particularly corrosive, you could consider a model that has an interior of plated or galvanized steel as an economical option. Ovens with double-wall construction and good insulation between the chamber and outer cabinet operate more economically, more uniformly, and have a cooler exterior surface for added safety.

Control Options

Many controller options are available ranging from simple analog dials with bimetallic thermostats to high-accuracy programmable digital PID controllers with data logging, calibration routines, self-diagnostic functionality, and even remote web access. Pretty neat stuff, but you’ll have to balance the cost of the features with the benefits. If you’re processing a lot of samples every day, or your lab is “lightly staffed”, it’s going to be helpful for an oven to have timed, automatic, or even remote operation and temperature protection set points. If entry-level technicians will use the oven, maybe simpler is better. The point is to think through available options and make an informed decision.

We hope this blog post has helped you make some sound decisions in selecting your next laboratory oven.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)