The evolution of concrete over the past century is marked by a steady increase in the compressive strengths attainable through improved mix designs and admixtures. Now included under the umbrella of high-performance concrete (HPC), higher-strength concrete mixes have opened the door for more durable concrete and safer structures. High-strength mixes also allow an increase in usable floor area when the size and number of supporting walls and columns in a structure are reduced.

Concrete with design compressive strengths higher than 6,000psi (41Mpa) is common now and mixes approaching 20,000psi (140Mpa) have been used in major projects. These high-strength mix designs present challenges when conducting conventional strength tests in the laboratory. Along with high compressive strengths, these mixes typically have a high modulus of elasticity. In simple terms, they are more brittle than "normal" mixes. Traditional compression testing machines may no longer be ideal for reliable testing of the full spectrum of today's high-performance concrete mix designs.

Are Traditional Compression Machines Up to the Task?

A compression machine that deflects excessively under high testing loads will have a shorter service life with more frequent repair and maintenance issues. Test results will be inconsistent, maintenance costs will be higher, and safety may be compromised.

Each strength test of a concrete cylinder or flexural beam is a strain on the load frame of a compression machine. High sample throughput, especially when testing high-strength concrete, places a strain on frame materials, welds, and connections. In time, fatigue cracking may appear in welds, or leaks might develop in hydraulic connections.

High-strength concrete samples under load in a compression machine may fail suddenly, sometimes explosively, once they reach peak load. The incidence rate of such failures is higher when unbonded capping (pad cap) systems are used. Such occurrences are at least startling, and the potential damage from flying debris is clearly a hazard for the operator or nearby personnel. Cumulatively, the shock of sudden failures eventually damages the hydraulic and electronic systems of a compression machine as well as the load frame.

Unintended eccentric loading from minor sample misalignment or inconsistencies within the test specimen can affect the accuracy and repeatability of test results. These inconsistencies are magnified when testing higher-strength mixes.

An often overlooked factor in the durability and performance of a concrete compression machine is the stiffness of the load frame. ASTM C39 clearly states requirements for the loading speeds and accuracy of the compression machine but says little regarding frame rigidity.

Rigid Compression Machines Make Your Concrete Testing Program Better

The American Concrete Institute (ACI), in their 363.2R Guide to Quality Control and Testing of High-Strength Concrete, cites research that establishes three essential facts about the stiffness of load frames:

- Rigid load frames reduce fatigue on materials and connections caused by high loads and load volumes, extending the machine's service life.

- Rigid load frames significantly reduce explosive sample failures at high loads when using unbonded capping systems.

- Rigid load frames compensate for eccentric loading caused by minor specimen misalignment or sample inconsistencies to produce more consistent and repeatable test results.

Gilson Leads the Way with Advanced Compression Machines

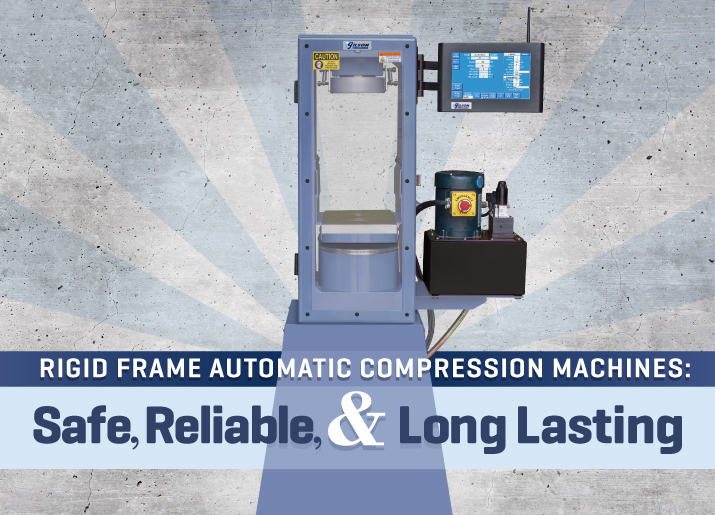

Gilson Rigid Frame (RF) Automatic Compression Machines feature a load frame that is laterally and longitudinally more than three times stiffer than conventional compression machines. The RF series design incorporates the same sophisticated Human-Machine Interface (HMI) and loading system as the rest of our Automatic Compression Machines. The HMI controller regulates the entire test cycle of load application and rate, break detection, and data collection. Loading rates and test protocol fully comply with the selected ASTM or AASHTO test method.

Gilson Rigid Frame (RF) Automatic Compression Machines

| Model1 | Total Capacity1 lbf (kN) | Recommended Maximum Typical Load, psi | Opening w/ Platens, WxH, in | Overall Dimensions WxDxH, in | Test Standard | ||

|---|---|---|---|---|---|---|---|

| 4in Cylinder | 6in Cylinder | ASTM | AASHTO | ||||

| AC-300 | 300,000 (1,334) | 19,100 | 8,500 | 10x14.5 | 32x19x57 | C39, C78, C109, C293 | T 22, T 97, T 177, T 106 |

| AC-400 | 400,000 (1,779) | 25,400 | 11,300 | 11x14.5 | 33x19x61 | ||

| AC-500 | 500,000 (2,224) | 31,800 | 14,100 | 12x14.5 | 35x20x60 | ||

| AC-300M | 300,000 (1,334) | 19,100 | 8,500 | 10x14.5 | 32x19x57 | C39, C78, C109, C293, C496, C469 | |

| AC-400M | 400,000 (1,779) | 25,400 | 11,300 | 11x14.5 | 33x19x61 | ||

| AC-500M | 500,000 (2,224) | 31,800 | 14,100 | 12x14.5 | 35x20x60 | ||

| AC-300MR | 300,000 (1,334) | 19,100 | 8,500 | 10x14.5 | 32x19x57 | C39, C78, C109, C293, C496, C469 | |

| AC-400MR | 400,000 (1,779) | 25,400 | 11,300 | 11x14.5 | 33x19x61 | ||

| AC-500MR | 500,000 (2,224) | 31,800 | 14,100 | 12x14.5 | 35x20x60 | ||

1 ACI 363.2R Report on High-Strength Concrete states the load frame should have a total capacity of "at least 20% greater than the expected ultimate load of the cylinders."

The RF Series is fully compatible with the Gilson Guardian Cloud Sharing Application. Samples marked with Guardian's QR code labels can be scanned before testing for automatic logging and reporting of strength results. Advanced testing for modulus of elasticity (MOE) and Poisson's ratio can be performed on available RF machines with M or MR model number suffixes.

Rugged fragment guard safety doors are standard on the RF series. The doors feature welded steel frames and are mounted on the front and rear of the load frames to close the testing chamber completely. Heavy-duty, long-wearing hinges and latches provide an extra margin of safety during testing. Shatter-resistant Lexan® inserts on the doors provide a clear view of testing status, resist impacts from sudden failures, and contain dust and debris.

We hope this article has helped you understand the importance of load frame rigidity when testing modern concrete mixes. Gilson RF series offers the greatest accuracy and reliability for the widest range of concrete mixes. Please contact us today to discuss your applications with Gilson's testing experts.

References:

- American Concrete Institute (ACI) 363.2R Guide to Quality Control and Testing of High-Strength Concrete

- ASTM C39 Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)