Asphalt permeability has a direct impact on the performance and longevity of pavements. Long-term internal exposure to water and water vapor in the asphalt voids is a significant factor in the premature deterioration of roadways. Air and water promote oxidation of the binder, causing it to become brittle and lose strength. Stripping occurs when water separates the binder from the aggregate surfaces and triggers a loss of strength and stability in the material.

What is Asphalt Permeability?

The hydraulic conductivity, or permeability, of asphalt is defined as the flow rate of water through interconnected voids in the compacted asphalt mixture. The rate of flow reflects the air-void content, aggregate size and shape, and degree of compaction of the mix. Along with other laboratory tests and mix design trials, measuring the permeability in asphalt mixes is a powerful tool to predict and improve the service life of flexible pavements.

How can I Measure Permeability?

This blog discusses methods and testing equipment for two simple asphalt permeability tests that can mitigate pavement problems over the long term. The apparatus for both tests are falling-head permeameters and measure the fall of water in a graduated standpipe through the asphalt matrix. An equation using Darcy's law describing the one-dimensional laminar flow of a fluid through a porous medium is used to calculate the samples' hydraulic conductivity or permeability.

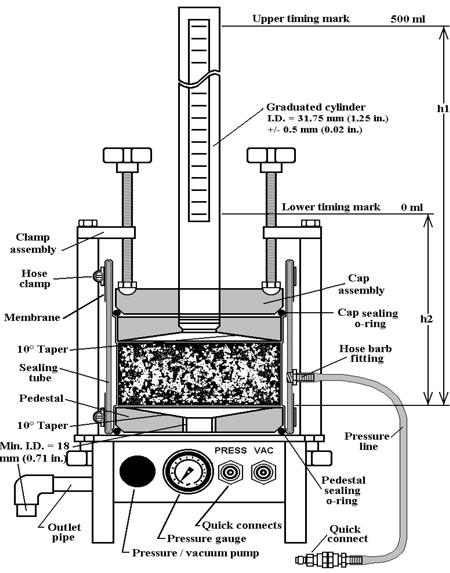

Water Permeability Test Apparatus, Graphic Credit: Florida DOT

Laboratory Asphalt Permeability Testing

Laboratory Asphalt Permeameters carry out laboratory asphalt permeability tests on cores or lab compacted samples and meet the requirements of Florida test method FM-5-565. The versatile lab permeameter is easy to set up and use and offers accurate and repeatable results in a laboratory setting. The device detects potential issues during the trial mix phase, allowing corrective adjustments to design mixes. Using drilled core samples can also help diagnose the source of problems with existing pavements or verify that materials will perform as expected.

Laboratory Asphalt Permeameters are available in 4in and 6in (102mm and 152mm) diameters to test laboratory compacted specimens or drilled cores. The 4in model does not meet the sample size requirements for FM 5-565. A test specimen is tightly fitted in a tubular latex membrane, which is pressurized to fill voids and prevent water flow around the outside of the sample. The sealed sample is confined within a metal cylinder on the 4in model or an acrylic cylinder on the 6in model, and secured with a threaded vertical clamping assembly.

A self-contained manual air pump provides a vacuum to draw the membrane against the cylinder, making it easy to insert the sample during setup. When ready to begin the test, the air supply line is switched over to the pressure connection, and the same pump pressurizes and seals the membrane on the sample. Pressure measurements are displayed on the built-in analog pressure gauge.

Saturating the sample requires repeated cycles of filling the 500cc graduated manometer tube with water and allowing it to drain through the sample until the elapsed times between cycles reach the specified repeatability level. After saturation is complete, the manometer tube is filled with water to an upper timing mark, and the time for the water to reach the lower timing mark is recorded. Complete details for the operation of the Laboratory Asphalt Permeameter can be found in the product manual.

Field Asphalt Permeability Testing

The NCAT Asphalt Field Permeameter performs permeability measurements directly on newly placed asphalt pavements in place. The method and equipment were developed at the National Center for Asphalt Technology, and the results correlate closely with laboratory permeability values. This quantitative and nondestructive test provides rapid and accurate permeability assessments of existing asphalt mats. The Field Permeameter equipment is cost-effective, the procedure is simple to perform with one person, and multiple tests can be conducted quickly without defacing the surface. The time and expense of mobilizing core drilling equipment and personnel are eliminated.

The NCAT permeameter operates with up to four tiers of clear polycarbonate graduated standpipes of different diameters. An alternate top tier is provided for extended test times in moderately permeable pavements. Each tier has a known surface area, and the bottom tier has a rubber gasket that defines the area of the largest tier. Water levels in a graduated standpipe will quickly drop when testing coarse or open-graded mixes. The increased surface area of the larger tiers slows down the rate of fall, allowing time to read and record the outflow accurately. Fine-graded and dense mixes reduce permeability, and the smaller diameters of the top tiers allow more accurate measurements of slowly falling water levels. The operator must select which tier will provide the best data for final calculations. Ultimately, test times should be long enough to record a measurable and steady rate of water level drop in the permeameter.

For complete details of the apparatus and test procedure, refer to the NCAT Asphalt Permeameter Operating Manual. A test site of about 1ft x 1ft (305mm x 305mm) square on the asphalt pavement is selected and prepared by brushing away the loose stone, dust, and debris. The pavement thickness at the test location must be known to complete the calculations for the permeability coefficient.

To prepare the permeameter, a moldable sealant is pressed onto the bottom of the baseplate around the outside of the opening. The device is then placed on the test area and seated using gentle, uniform foot pressure. It may be necessary to add the included surcharge weights to maintain a leakproof seal. A tube is used to fill the vessel with up to a gallon (3.9L) of water to begin the test. While observing the water level as it drops, a tier is selected for measurement where the fall rate is slow enough for accurate observation but fast enough for timely completion of the test.

NCAT Permeability Test Apparatus Setup, Photo Credit: Iowa DOT

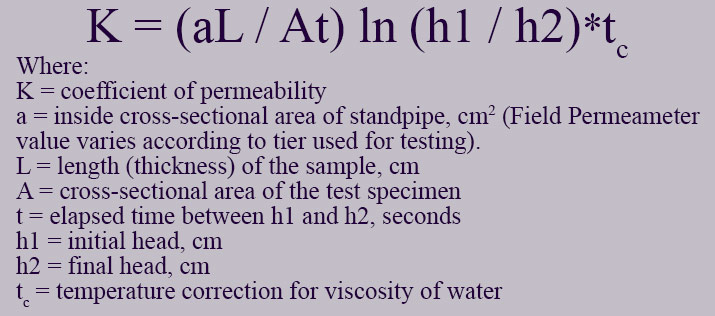

A water level and start time are recorded for the selected tier, and a final water level and total elapsed time at the conclusion. All recorded measurements must be taken from the same tier. The length of time, total water volume values are used to calculate and report the permeability coefficient, as seen in the equation below. Total test times are highly variable but generally do not exceed five minutes.

Calculating the Coefficient of Permeability

For both types of test methods and equipment described, the coefficient of permeability, K, is determined using the same equation derived from Darcy's law:

We hope this article has helped you understand the significance of asphalt permeability and the methods and equipment used to measure it.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)