Tests Performed on SCC and the Equipment Used

Self-consolidating concrete (SCC), sometimes called self-compacting concrete, is defined by the American Concrete Institute (ACI) as “Fresh concrete that can flow around reinforcement and consolidate within formwork under its own weight without vibration.” The description, published in the ACI report 237R-07, goes on to say, “… SCC is a highly flowable, non-segregating concrete that can spread into place, fill the formwork, and encapsulate the reinforcement without any mechanical consolidation. In general, SCC is concrete made with conventional concrete materials and, in some cases, with a viscosity-modifying admixture (VMA).”

Background of SCC

We have already discussed the history, applications, and primary characteristics of self-consolidating concrete in a related Gilson blog post on concrete workability. This article recaps some details but the focus is on the most widely used tests and testing equipment.

SCC was developed in the mid-1980s to improve the efficiency of concrete placement and ensure proper consolidation in areas with complex formwork and congested reinforcing steel. As the popularity of the new mix design increased, users discovered that it could improve performance and reduce cost in other areas:

- Greater efficiency for placement and finishing operations

- A higher rate of placement, improving productivity and efficiency

- Allows more flexibility in the design, quantity, and placement of reinforcing steel

- Improved cosmetic surface quality for architectural concrete, reducing the need to repair surface voids and other blemishes

Note: As stated in the ASTM and AASHTO standard test methods, values expressed in inch-pound or SI units of measure are used independently, regarded separately, and may not be exact equivalents.

SCC Tests and Testing Equipment

The tests described here all cite the ASTM C1758 practice for filling the respective molds with SCC without rodding, tamping, or consolidation.

| SCC Test | ASTM | AASHTO | Measured Properties | Essential Testing Equipment |

|---|---|---|---|---|

| Slump Flow | C1611 | T 347 | Flow Diameter & filling ability | Slump Cone Base Plate Strike-Off Bar Measuring Tape |

| Flow Rate1 (T50) or 2 (tv) | C1611 | T 347 | Rate of Flow | Stopwatch |

| Visual Stability Index (VSI)1 | C1611 | T 351 | Visual observation of mix stability | Measuring Tape |

| J-Ring/Passing Ability | C1621 | T 345 | Passing ability through reinforcing steel & filling ability | Slump Cone or Modified Slump Cone J-Ring Base Plate Strike-Off Bar Measuring Tape |

| Static Segregation | C1610 | — | Resistance to segregation & stability | Static Segregation Column Balance Strike-Off Bar 4.75mm (No.4) Rectangular Sieve) |

| L-Box | Pending | — | Flow rate, distance, & passing ability | L-Box Strike-Off Bar Measuring Tape |

| Penetration Test | C1712 | — | Resistance to segregation | SCC Penetration Apparatus Slump Cone Mold Base Plate Strike-Off Bar |

| V-Funnel Flowability | — | — | Filling ability & flow rate | V-Funnel Apparatus 36in Strike-Off Bar |

1In ASTM C1611, flow rate and VSI methods are presented in the appendix as nonmandatory information.

2The V-Funnel test does not currently have an ASTM or AASHTO standard test method. The test and apparatus are described in European Standard EN 12350-9.

Slump Flow: ASTM C1611/AASHTO T 347

Slump flow evaluates the horizontal free-flow characteristics of the mix and its filling ability. It is the most common workability test for self-consolidating concrete.

A conventional ASTM C143 concrete slump cone is positioned on a suitable surface or base plate in an upright or inverted position. The cone is filled with a SCC sample in one lift and struck off without consolidation. The slump cone is lifted vertically at a specified rate, allowing the concrete to spread freely on the base plate. After the flow has stopped, the average diameter of the concrete sample is measured and recorded as the slump flow.

The flow rate (T50) is a related value that can be measured with a stopwatch during the slump flow test by recording the time it takes the flow to reach a diameter of 20in (500mm), as indicated by an inscribed circle on the base plate.

| Appearance | Description | VSI Value |

|---|---|---|

| No evidence of segregation or bleeding | Highly Stable | 0 |

| No evidence of segregation and slight bleeding observed as a sheen on the concrete mass | Stable | 1 |

| A slight mortar halo ≤10 mm [≤0.5 in] and/or an aggregate pile in the concrete mass | Unstable | 2 |

| Clear segregating by evidence of a large mortar halo >10 mm [>0.5 in] and/or a sizeable aggregate pile in the center of the concrete mass | Highly Unstable | 3 |

Visual Stability Index (VSI) for SCC

The Visual Stability Index (VSI) is a qualitative evaluation of the stability of an SCC mix made by observing the appearance of the concrete sample at the completion of the slump flow test and assigning a VSI value from the chart shown.

The operator should be aware that details vary slightly between the ASTM C1611 and AASHTO T 347 versions of this method:

- ASTM lists procedures for filling the mold in upright or inverted positions, while AASHTO only allows filling in the inverted position.

- A base plate with specified concentric markings is required by AASHTO but optional for ASTM.

- The T50 flow rate measurement as part of the slump flow test method is required in the AASHTO test but optional for ASTM.

- The final slump flow average is reported to the nearest 1/4in (5mm) for the AASHTO test and to the nearest 1/2in (10mm) for ASTM.

J-Ring/Passing Ability: ASTM C1621/AASHTO T 345

The J-ring test is performed in conjunction with the slump flow test to establish a passing ability value, which determines how readily an SCC mix flows around and through reinforcing steel placements. The apparatus and some procedures are shared with the slump flow test, with the addition of a 12in (300mm) diameter J-ring, mounted with sixteen evenly placed 5/8in (16mm) vertical steel bars. A modified slump cone with no foot tabs is required if the cone is to be placed upright inside the ring (procedure “A” in the ASTM test).

The ring assembly is positioned on the base plate, and the slump cone is centered inside the ring in either the upright or inverted position. A concrete sample is placed in one lift without consolidation, and the cone is lifted vertically to allow the sample to spread through the bars. After the flow has stopped, the average final diameter of the concrete is measured and recorded as the J-ring flow.

| Passing Ability Value | Blocking Assessment |

|---|---|

| 0 to 25mm (1 to 1in) | No visible blocking |

| >25mm to 50mm (>1in to 2in) | Minimal to noticeable blocking |

| >50mm (>2in) | Noticeable to extreme blocking |

Blocking Assessment for J-Ring Test

The difference between the J-ring and slump flow spread diameters is used to describe the degree that mix characteristics block the flow of the concrete around obstructions.

As with the slump flow test, there are minor differences between the ASTM and AASHTO methods.

- ASTM lists separate procedures for filling the mold in either the upright or inverted positions, while AASHTO allows filling in the inverted position only.

- The final average of the spread diameter is reported to the nearest 1/2in (10mm) for ASTM and the nearest 1/4in (6mm) for AASHTO.

- The AASHTO test method specifies height measurements of the concrete sample at completion.

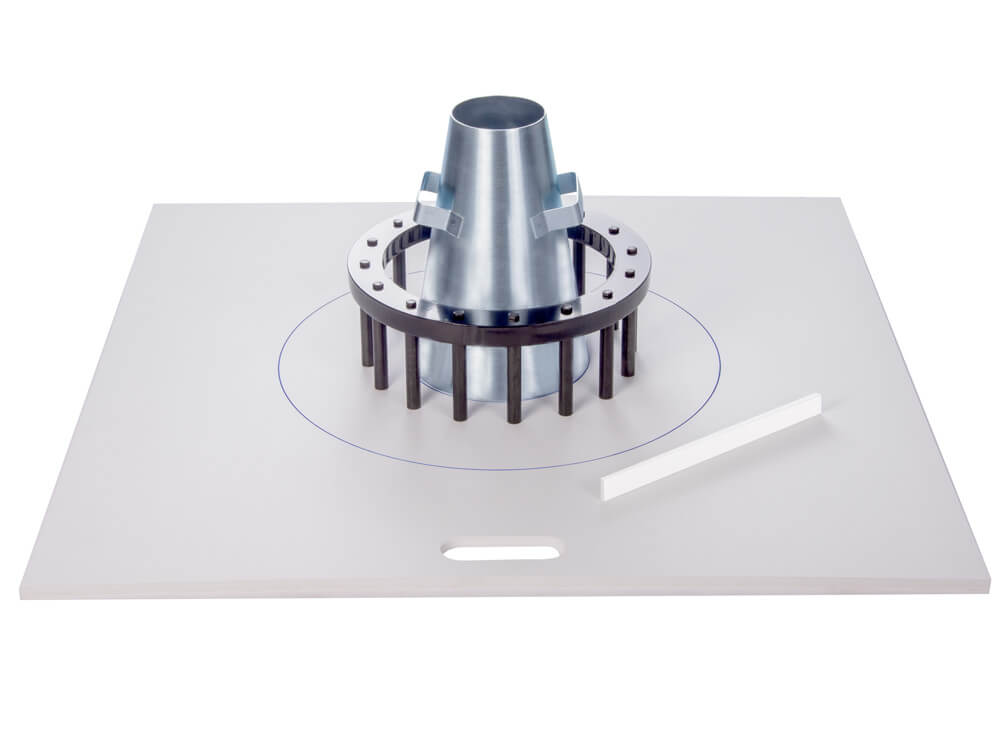

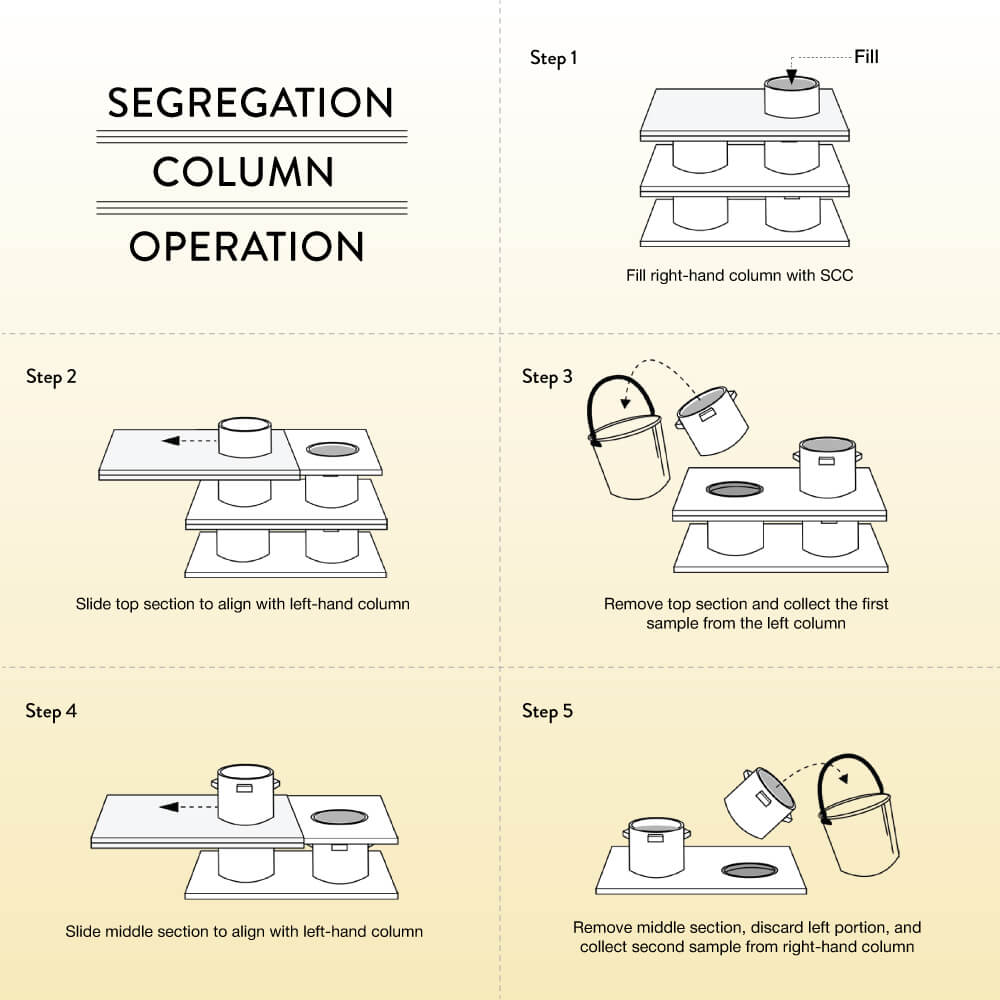

Static Segregation Column: ASTM C1610

The static segregation column test determines the stability of an SCC mix by measuring the extent that the coarse aggregate fraction separates out of a fresh sample by gravity. The test was developed for laboratory use but is increasingly used in field applications.

A cylindrical column divided into three sections is filled with a sample of fresh SCC mix without tamping or consolidation. After allowing a specified time for settling, the contents from the top and bottom column sections are separated and retained, and material from the middle section is discarded. The top and bottom sections are washed separately over a 4.75mm (№ 4) rectangular sieve and the mass of the coarse aggregate fractions remaining is determined.

The static segregation value is calculated by a percentage comparison between the masses of the two fractions. The test method assesses the suitability of a mix design for a particular application.

L-Box: ASTM Test Pending

The L-box test quantifies the flowability of SCC in confined formwork and the blocking effect of steel reinforcing bars. The test is primarily performed in Europe and by some DOTs in the USA in a laboratory setting. An ASTM standard test method is pending.

The vertical portion of the L-box is a rectangular hopper with a moveable gate at the bottom. The hopper is filled to the top with the concrete sample and struck off without tamping, vibration, or consolidation. Lifting the gate allows the SCC to flow around the steel bars and into the horizontal trough.

When the flow has stopped, the measured concrete depths at the gate and the end of the trough are compared, and a blocking value is calculated. Some versions of the test method require the timing of the flow with a stopwatch.

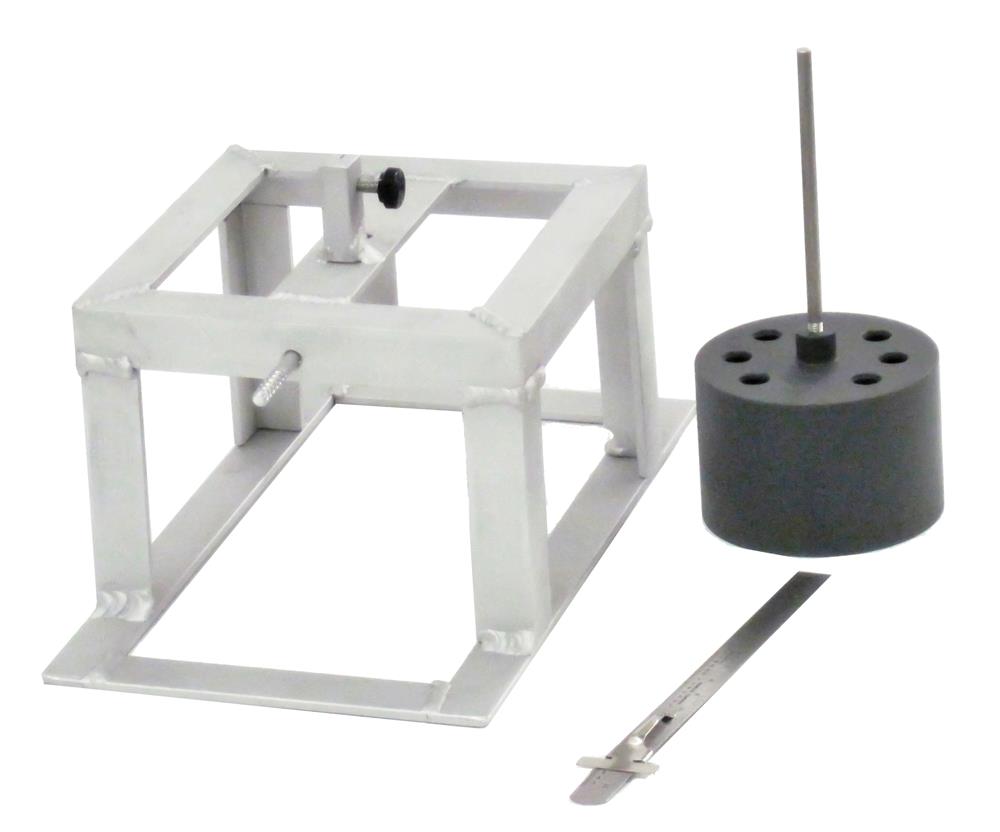

SCC Penetration Test: ASTM C1712

The rapid penetration test estimates the likelihood that separation of the mortar and coarse aggregate components (static segregation) will occur in an SCC mix. This simple test is easily performed on fresh concrete during placement and takes little time.

| Penetration Depth | Resistance to Static Segregation |

|---|---|

| ≤10mm | Resistant |

| >10mm to 25mm | Moderately Resistant |

| ≥25mm | Not Resistant |

Static Segregation Resistance

A sample of SCC is placed in an inverted slump cone without tamping or vibration and allowed to stabilize for 80 seconds. The penetration test apparatus is positioned on the slump cone, and the hollow cylinder is lowered onto the concrete surface. An initial reading is recorded, then the cylinder is allowed to penetrate the sample under its own weight for 30 seconds. A final reading is recorded, and the total penetration depth is calculated and reported to the nearest millimeter.

V-Funnel Flowability Test: European Standard EN 12350-9

The V-Funnel test characterizes the flow rate of the concrete mix and its ability to fill narrow form spaces with no consolidation effort. The test apparatus consists of a metal V-shaped funnel with an outflow opening at the bottom. The opening is closed by a hinged watertight quick-release gate. The device is mounted on a stand at a convenient working height.

A 10L (2.6gal) SCC sample is poured evenly into the funnel in one motion and the top is struck off with a 36in (914mm) straightedge. After a 10 second delay, the bottom gate is opened, allowing the sample to flow into a receiving container placed below. The outflow is timed with a stopwatch, starting when the gate is opened and stopping when it is possible to sight down through the funnel and see the container below. The time (tv), is recorded to the nearest 0.5 seconds as the flow time.

We hope this article has helped you understand the typical tests performed on SCC and the available testing equipment. For help with your particular application, please contact the testing experts at Gilson.

More Resources:

- ACI 237R-07 Self-Consolidating Concrete

- ASTM STP 169D, Significance of Tests and Properties of Concrete and Concrete-Making Materials, Chapter 56: Self-Consolidating Concrete (SCC)

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)