Using Soil Relative Density to Determine the Degree of Soil Compaction

Testing soil compaction is a universal practice to document the density of in-situ soil formations or engineered compacted soil fills during the construction process. Knowledge of soil density allows reliable estimates of strength and stability and reduces settlement and displacement for structures, pavements, and embankments.

The degree of soil compaction is determined with field density tests using sand-cone, nuclear gauge, or volumetric test methods. The density is measured in place and compared to reference densities determined by laboratory testing to calculate a ratio or percentage of compaction compared to maximum density. Field density tests are also helpful in assessing the strength and bearing capacity of native or existing soils in advance of structural loading.

How Soil Characteristics Influence Compaction

The laboratory maximum density that field tests refer to depends on the particular type of soil. The two major classes of engineering soils are cohesive and cohesionless, differentiated by the percentage of fines (clay and silt-size particles) that pass a 75µm (No. 200) test sieve.

Cohesive Soils

Cohesive soils contain a significant fraction of clay and silt particles, generally more than 15%. Most particles adhere to one another in the presence of moisture and exhibit some degree of plasticity. The density that these soils achieve during compaction is directly related to their moisture content. In a previous blog article, we examined the moisture-density relationship of fine-grained soils in detail.

Cohesionless Soils

Free-draining and compactible coarse-grained soils and aggregate mixtures that do not exhibit cohesive qualities have fines fractions between approximately 5% and 15%. These materials exhibit little or no cementing between individual particles. Moisture content does not affect these soils' dry density in the same way as cohesive soils when compactive forces are applied, so a Proctor test will not result in a typical moisture-density curve.

Maximum Density & Optimum Moisture of Cohesive Soils

Laboratory Proctor tests for cohesive soils (ASTM D698, D1557, and others) are performed by compacting soil samples into a mold at predetermined moisture contents. Separate specimens of the soil sample are prepared with incrementally increasing moisture contents to establish the moisture/density relationship curve. Each specimen is compacted into the mold and weighed to create successive "points" for plotting a moisture/density curve. The entire process is detailed in this previous Gilson blog.

For each of the first few points, there is an increase in the dry unit weight as the soil becomes easier to compact. For the last couple of points, the dry weight decreases as the added water displaces soil material in the mold. Graphically plotting the points for moisture content vs. dry unit weight produces the characteristic curve that defines an optimum moisture percentage. The same principles apply to native or compacted soils at the project site. When field density tests are performed, results are compared to the moisture/density curve to find the degree of compaction. Moisture tests help in decisions to add moisture or dry back soils to be closer to optimum moisture.

Relative Density of Cohesionless Soils

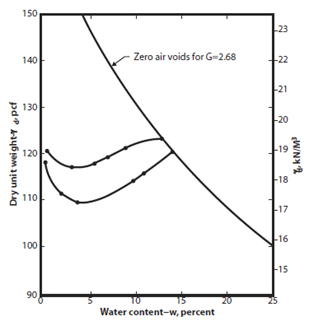

As noted above, granular soils with few fines and varying moisture contents do not respond to compaction efforts in the same way as cohesive soils. Proctor tests performed on soils with 5% to 10% fines and a high fraction of sand-sized particles may even result in an "upside-down" curve showing a reduction in density due to the effects of sand bulking.

From ASTM MNL70-EB Manual 70, page 15

Tech Note: Bulking occurs in some sands at low to medium moisture contents. A film of water forms around particles and pushes them away from one another, causing an increase in void ratio and corresponding decrease in density. Once the sand or fine aggregate is fully saturated, bulking is no longer a factor. With the application of compactive forces, the void content is easily reduced and density increases.

This reaction to moisture levels can be advantageous when wet field conditions make it difficult to adequately compact cohesive soils. Cohesionless soils are easily densified with compaction equipment when wet. Still, evaluating the degree of compaction in granular soils requires a different sort of laboratory reference test.

How is Relative Density Calculated?

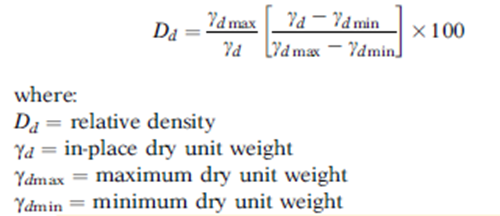

Field density tests establish the dry unit weight soils, but a unit weight alone does not describe whether the soil is loose or dense. Instead of the Proctor test, results from maximum density (ASTM D4253) and minimum density (ASTM D4254) laboratory tests are referenced to calculate the relative density of the in-place soil. ASTM defines relative density as "…the degree of compactness of a cohesionless soil with respect to the loosest and densest condition…". The following formula is used to find the relative density of soil in place:

From ASTM D4253

Some practitioners favor alternatives to using relative density as a quality control method. One method is to calculate the compaction percentage based only on the D4253 maximum density value. Another option is to use maximum dry unit weight data from ASTM D698 or D1557 Proctor moisture/density relationship tests. These alternate methods should be employed on a case-by-case basis only after analysis and guidance from a qualified geotechnical engineer.

Testing for Minimum & Maximum Densities

The two ASTM standard test methods for minimum and maximum density offer numerous alternate methods, devices, and mold options. The maximum particle sizes of the samples govern required specimen masses, mold sizes, and material placement devices. This article will focus on the preferred and most commonly used procedures and equipment.

Minimum and maximum laboratory test procedures are not difficult to perform but require attention to detail, specified equipment, and adherence to the protocol for periodic calibration of the equipment to produce accurate results. Calibration procedures for the molds, base plate, dial gauge sets, and vibratory table require additional apparatus and are detailed in ASTM D4253. Full calibration is typically required annually or after 1,000 uses.

Mold Sizes & Sample Mass for Minimum Density Tests

| Maximum Particle Size, 100% Passing, mm (in) | Specimen Mass Required, kg (lb) | Placement Device for Minimum Density | Mold Size Required, ft³ (cm³) |

| 75 (3) | 34 (75) | Shovel or Large Scoop | 0.500 (14,2000) |

| 38.1 (1-1/2) | 34 (75) | Scoop | 0.500 (14,2000) |

| 19.0 (3/4) | 11 (24.3) | Scoop | 0.100 (2,830) |

| 9.5 (3/8) | 11 (24.3) | Pouring Device, 1in (25mm) Spout | 0.100 (2,830) |

| 4.75 (N0. 4) | 11 (24.3) | Pouring Device, 0.5in (13mm) Spout | 0.100 (2,830) |

The Minimum Density Test

The ASTM D4254 minimum density test determines the unit weight of free-draining soils or aggregate mixtures in their loosest possible state. The oven-dried sample is carefully and loosely placed in a 0.5ft³ (14,200cm³) or 0.1ft³ (2,830cm³) Sample Mold using a Scoop or unique Pouring Funnels. Placement devices and mold sizes are selected based on the maximum particle size of the sample, as shown in the chart above. The sample-filled mold is weighed, and the dry unit weight is calculated by dividing the consolidated sample's mass by the calibrated mold's volume. The procedure must be repeated until consistent unit weight values (±2%) are obtained.

The Maximum Density Test

The ASTM D4253 maximum density test specifies the same Relative Density Molds used for the minimum density methods. The large and small capacity molds are each sold separately and include a guide sleeve and a surcharge weight with a base plate. Depending on the mold capacity, the weight of the surcharges is either 190lb (86.2kg) or 56.5lb (25.5kg).

A vibratory table to consolidate the sample to its maximum density is required, and two different table types are acceptable. Gilson's Relative Density Vibrating Table is driven by the recommended electromagnetic vibrator and features an adjustable amplitude controller for easy and precise calibration. Eccentric or cam-driven tables are also acceptable.

Dry vs. Wet Maximum Density Procedures

There are options within the maximum density test to consolidate samples in either oven-dried or wet moisture conditions, with a recommendation that both methods be used if the soil being tested is unfamiliar or from a new project. The dry method is more convenient and faster to run; however, the maximum density of some soil types when wet is significantly higher than when dry, which directly affects field relative density values.

Procedure for Oven-Dried Samples

For oven-dried samples, filling the mold for the maximum density test mirrors the minimum density procedure; Scoops or funnels are used to deposit the sample loosely, taking care to avoid segregation. When maximum and minimum tests are performed on the same sample, it makes sense to complete the minimum density test first so that the mold is filled and ready to be consolidated for the maximum density test.

Once the mold is filled, the base plate is seated on the sample, and the mold is secured to the vibratory table. After attaching the guide sleeve to the mold, the surcharge weight is lowered onto the base plate. The surcharge weight may be too heavy for one or even two people to manage and may require a hoist or pulley system.

Adjust the controller to the prescribed amplitude setting determined during the calibration of the vibratory table and vibrate the sample and mold assembly. Vibration should continue for 8 minutes on tables operating at a frequency of 60Hz, or 10 minutes on tables with a 50Hz operating frequency.

Procedure for Wet Samples

The wet method for maximum density determinations requires that the prepared sample contains enough water to reach saturation during the densification process. The procedure begins with the empty mold attached to the vibratory table, and the vibration turned on.

The sample material is slowly added to the vibrating mold while ensuring that a small amount of free water accumulates on the surface, either from vibration or by carefully adding water in small amounts. The vibration level should be adjusted so that excessive fluffing or "boiling" of the surface does not occur. The filling should be complete within 5 or 6 minutes, and free water should be removed from the surface during the final minute.

Once the filling process for dry samples is complete, the vibration of the mold assembly and specimen for maximum consolidation can proceed as described for samples using the dry method.

Volumetric Measurements and Calculations for Maximum Density

The surcharge weight and guide sleeve are removed after the vibration cycle while the surcharge base plate is left in place. The Relative Density Gauge Set attaches to the guide brackets of the mold and measures the distance from the top of the mold to the top of the base plate. Correcting this measurement for the thickness of the base plate yields the final sample height used to compute the volume. Initial dial readings for each mold can be determined during the calibration process and only need to be checked annually.

The mold and sample are weighed, and the weight of the mold is subtracted to find the total sample mass. For the wet process, a moisture content test is performed to correct samples to the dry unit weight. Sample volume and mass are used in the formula for maximum density:

We hope this article has helped explain the basics of soil relative density as a way to determine the degree of soil compaction.

Resources

- ASTM D4253, Standard Test Methods for Maximum Index Density and Unit Weight of Soils Using a Vibratory Table

- ASTM D4254, Standard Test Methods for Minimum Index Density and Unit Weight of Soils and Calculation of Relative Density

- ASTM MNL70-EB (Manual 70), Quality Control of Soil Compaction Using ASTM Standards

- Engineer Manual EM 1110-2-1906, Laboratory Soils Testing, United States Army Corps of Engineers

- ASTM MNL12163M, Manual of Laboratory Compaction Tests

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)