- Log in

- Favorites List

-

Shopping Cart

You have no items in your shopping cart.

- Gilson Chat

Sieve Shakers for Particle Sizing Analysis

A sieve shaker automates the agitation of particles for particle separation and sizing distribution for a range of materials to meet quality control and quality assurance requirements. The advantages of shakers include consistency, accuracy, and repeatable separations compared to manual sieve shaking methods for particle sizing. Lastly, shakers save a considerable amount of testing time.

For bulk coarse aggregate separation, see our full line of Screen Shakers. Not sure which sieve shaker you need? See our comparison chart or our blog An Expert Guide To Selecting A Shaker.

Sieve Shakers for Test Sieve Particle Sizing Analysis

Gilson offers a large selection of shakers with varied sieving motions and opening sieve mesh size compatibility for particle sizing analysis of a wide range of material sizes. Matching the capabilities of a sieve shaker machine to specific characteristics of the sample material saves time and effort while providing repeatable results.

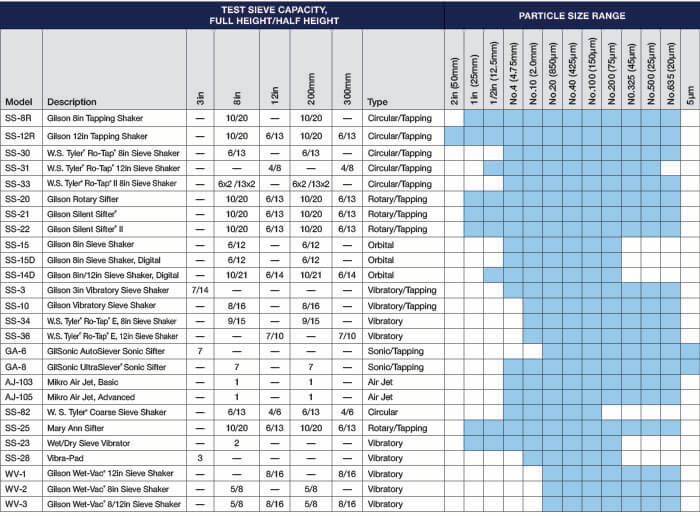

Click the Sieve Shaker Comparison Table above to enlarge, print, or download.

The table compares test sieve capacity, shaker agitation, and particle size range.

Agitation lifts and reorients material, allowing more opportunities to pass through the sieve mesh opening size. Sieving machines provide consistent agitation of samples, improving the passage of material and overall consistency and ensuring reproducible results between tests.

Gilson's laboratory shakers offer various agitation methods to ensure the efficient separation of materials with different densities and textures. Selecting the right agitation method can be determined by the minimum size to be separated, particle size, wet or dry sieving method, and material characteristics like resistance to agglomeration and static electric factors. Select from various types of agitation methods, including circular, tapping, rotary, orbital, vibratory, sonic, or air jet.

Some vibratory and mechanical shakers without cabinet enclosures can be modified for wet sieving. Gilson also carries a wet-sieving vibratory shaker featuring a system for pumping and recycling wash water and vacuum systems to increase material throughput, which is popular for particle-separating coal or coke. Gilson also offers Wet-sieving accessories to supply and drain away wash water from the sieve stack.

Other factors in selecting a shaker include degradation, static attraction, desired sample volume, noise level during operation, and agglomeration.

Newer-model Gilson shakers are equipped with an easy-to-use clamping system to secure and lock sieves in place. All sieve shakers come with a mechanical or digital timer, except the 8in Wet/Dry Vibrator.

- Tapping enhances performance through aggressive circular actions and repetitive two-way tapping of the sieve stack. The tapping feature is available in a number of models with vibratory, circular, orbital, and other primary actions. Repetitive mechanical tapping of the sieve stack reorients particles, promotes passage of near-size particles, and prevents blinding. Mechanical tapping shakers perform well with materials in a wide range of sizes and improve the passage of fines for most materials.

- Rotary sifters hold a sieve stack in an enclosed cabinet tilted at an angle. Rollers rotate the sieves continuously, reorienting particles. While multiple hammers tap against sieves to promote the passage of near-size particles. Rotary sifters do not have exposed moving parts, are relatively quiet and dust-free, do not require a clamping system, and are preferred by many state DOTs.

Gilson’s Rotary and Silent Sifter® models and the Mary Ann® sifters offer the tapping action. Rotary lab sifters work well for mineral aggregates and other materials from No. 4 to No. 635 (4.75mm to 20μm).

- Orbital actions mimic the motion of hand sieving and are a cost-effective choice to use with free-flowing materials. The particles are rolled around on the mesh surface until they fall through an opening. The sieve stack is suspended from a single point at the top while the base is moved in an orbital motion. A bumping action is sometimes introduced as the sieve stack oscillates.

These units work well with most materials ranging in size from No.4 (4.75mm) to No.200 (75μm) and come with a manual or digital timer.

- Vibratory units use electromagnetic energy to agitate particles. Vibratory shakers are an ideal setting for creating a fluid bed of materials. The materials move across the mesh to optimize the number of openings tried by the sample material. Adjustments for vibration amplitude and frequency on some shakers allow optimization for a wider range of materials.

This type of sieve shaker equipment performs well on most materials sized between No. 10 (2mm) and No. 635 (20μm). Available vibratory styles include 3 and 8in models, WS Tyler® Ro-Tap®, and wet-dry units.

A pause function on better-quality vibratory shakers offers an effect similar to the tapping feature. Programming a pause into the test cycle causes particles to briefly stop and then reorient themselves when agitation resumes.

- Sonic uses up to 3,600 sonic energy pulses per minute to oscillate an air column enclosed within the sieve stack. This continuous agitation paired with programmable horizontal and vertical tapping reorients particles to the mesh surface for accurate separations. The GilSonic AutoSiever and UltraSiever® sonic sifters offer precise sizing of small samples of powders as fine as 5µm.

- Circular moves the sieve stack on a flat oscillating plane to evenly distribute particles around most of the sieve surfaces. The circular action allows particles to randomly fall through openings. Models with both circular and tapping action offer enhanced performance and efficient separation for a wider range of materials.

Units with this feature alone are adequate for coarser free-flowing materials between No. 4 (4.75mm) and No. 100 (150μm). The addition of a tapping mechanism enhances performance and allows efficient separation over a wider range of materials from 1 or 2in (25 to 50mm) to No. 635 (20μm).

- Mikro Air Jet Sieve™ offers accuracy and reliable results for dry powders. These units use positive air pressure through a rotating slotted nozzle to gently fluidize samples in a single 200mm diameter sieve. Fines are collected in a canister with a vacuum system.

This unit is best used for materials from No. 4 to No. 635 (4.75mm to 20μm). Basic and Advanced models are available.

- Wet-Vac® systems are self-contained, wet-sieving particle sizing units widely used in testing applications for coal and coke. Testing with these heavy-duty systems can closely simulate production conditions. Water tanks, pumps, and spray heads are built-in vibratory shakers, and fines are collected in filter paper assemblies. Select from models that accommodate 8 or 12in sieves or accommodates both 8 and 12in sieve diameters.

For more information on Sieve Shakers for Particle Sizing Analysis, here are our related blogs:

- An Expert Guide to Selecting a Sieve Shaker

- Sieve Analysis of Coarse Aggregate: From the Field to the Lab

- Steps to Reduce Nuisance Dust & Prevent Silica Exposure

- Streamlining Aggregate Gradation Tests: Tips and Tricks

- Dust and Noise: Can Better Equipment Help? Part 2: Noise

- Sonic Sieving: The Solution for Particle Size Problems

Filter by: