Table of Contents:

- Defining Curing of Concrete

- Initial Curing

- Final Curing

- Methods for Concrete Curing

- Moist Curing Room Equipment

- Water Curing Equipment

What is Concrete Curing

The curing and strength development of concrete is a complex chemical hydration process that begins the moment water contacts the cement ingredients. Successful sampling, curing, and strength testing of concrete depends on following the rules imposed by the process itself.

Early-age (green) concrete is very sensitive to disturbances and temperature variations. As a result, curing of the samples is carried out in two stages:

- Initial curing for the first day or two occurs on the job site. Immediately after molding, the fresh concrete samples are placed in a protected environment where they gain enough strength to allow them to be transported to a testing laboratory.

- Once in the lab, the samples are removed from the molds and begin the longer-term phase of final curing.

Initial, or Field Curing

It’s just another day at the office, or in this case, the job site, and the concrete strength specimens you’ve just made have started their initial curing. The ASTM C31 and AASHTO T 23 Practices for Making and Curing Concrete Test Specimens in the Field are clear on what is needed for this period of fewer than 48 hours when the samples reach the final set and start their strength development:

- Moisture loss must be prevented.

- Ambient temperature must be maintained between 60°F and 80°F (16°C and 27°C) for most concrete types.

While not as clearly stated in the practice, it is also known that impact, vibration, or other disturbances at this stage directly affect the strength development of concrete, so the samples must also be protected from physical forces.

Concrete curing boxes are built to meet the demands of initial curing and enhance the efficiency of your field operations with portability and convenience. Options are available for heating, heating, and cooling, or sample temperature and moisture control by immersion in circulating water. The units are easily transported between projects or stored at the lab between uses.

Final, Laboratory Curing

At the end of the initial curing period in the field, the specimens are ready to be transported back to the testing laboratory. There, they begin a final curing phase until they reach an age of 7 days, 28 days, or more before they are tested for compressive or flexural strength. But how do you store them so that they will cure properly and continue to gain strength until they are tested? This can all be very challenging.

Adequate protection of concrete samples from vibration, jolting, and temperature extremes during the transportation is critical and could affect strength test results if overlooked. Gilson’s Field Curing Chest and Cylinder Transport Racks safeguard samples for reliable test results.

Accurate strength tests for concrete, grout, and masonry specimens in the form of cylinders, beams, or cubes begin with proper curing as required in their respective ASTM and AASHTO standards, yet one of the most common errors found in CCRL (Cement and Concrete Reference Laboratory) audits is the inability to maintain specified curing temperatures and moisture levels in the laboratory. Improper curing conditions directly inhibit optimal strength development of concrete strength specimens.

Moisture Curing Rooms or Concrete Curing Tanks are two acceptable and widely used methods for curing samples for concrete strength tests. Specific requirements for each are outlined in ASTM C511 and AASHTO M 201 standard specifications.

Concrete Curing Methods

An informal poll conducted by the AASHTO Materials Reference Laboratory (AMRL) indicated the number of laboratories with Moisture Rooms versus Curing Tanks is evenly split, so both are equally popular and offer a viable solution. In this post, we'll educate you on the pros and cons of each method to help you determine which procedure is right for your lab.

Concrete Curing Rooms

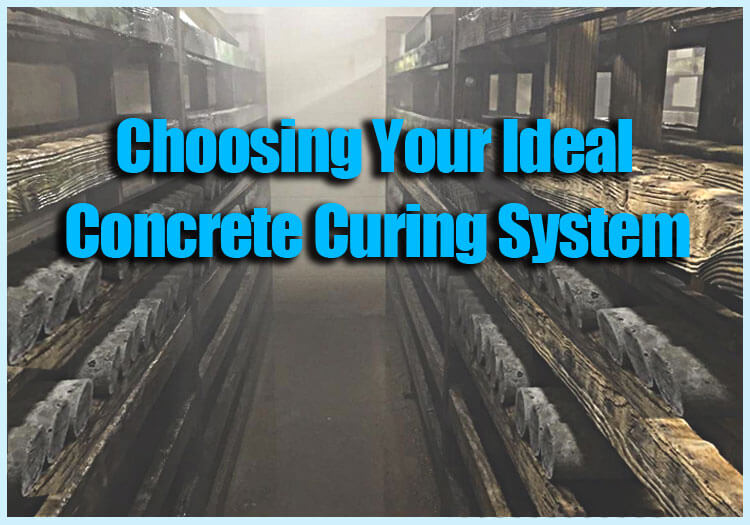

Moisture Curing Room design looks like saunas or walk-in refrigerators full of fog. Ranging from the size of a small closet to a large room, they can be prefabricated modular units or constructed in place using masonry blocks or other moisture-resistant materials. They are sealed and often have an exterior panel mounted with temperature and humidity monitoring instruments.

Photo Credit: Braun Intertec

Diverse methods are employed for maintaining required temperature and moisture levels in the room, from simple fogging humidifiers to systems that blend hot and cold water supplies and distribute temperature-controlled water through a system of atomizing spray heads. Rooms using stand-alone foggers require a separate method of controlling concrete curing temperature to the specified 23.0±2.0°C (73.4±3.5°F).

Specimen storage is on racks or shelving, configured for maximum exposure of the specimens to moist air. Specifications require relative humidity levels to be maintained to at least 95%, such that the specimen surfaces both look and feel moist. Temperature and humidity levels must also be recorded.

Pros:

- The best choice for greater quantities of larger specimens

- Easy to organize specimens by age and type

- Specimens are easier to access and handle with pallet jacks and carts if needed

Cons:

- Expensive to build or buy

- Complex installation sometimes requires the integration of other equipment and systems

- Maintenance can be expensive and time-consuming

Our Recommendations:

Moisture Room Control Panel for a wide range of room sizes. This wall-mounted control panel features:

Moisture Room Control Panel for a wide range of room sizes. This wall-mounted control panel features:- A complete automated control solution, blending hot and cold water supplies for distribution through Atomizing Spray Heads. Requires installation of supply and distribution lines.

- Easy-to-read digital controller display for easy input of temperatures.

- Manual bypass system for continuous maintenance of specified temperature and humidity levels if power is interrupted.

- Space for mounting of temperature chart recorder or data logger

Aquafog® GT 500 Fogging Fans for humidifying rooms up to 1,600ft² (149m²).

Aquafog® GT 500 Fogging Fans for humidifying rooms up to 1,600ft² (149m²).- Tap water from ordinary water supplies is forced past the high-speed fan blades

- Centrifugal force and high-speed airflow atomize water droplets to produce a uniform distribution

- Stainless steel, polyethylene, and anodized aluminum construction means a long, corrosion-free service life

- Units with output up to 15gal (57L) per minute are available

Temperature Tracking and Humidity Monitoring

Moist Rooms for concrete curing must record temperatures once every 15 minutes, and the data must be evaluated a minimum of once per week. Instruments for recording humidity levels are optional, but Gilson recommends observations and measurements frequently as a good practice.

- Temperature Recorders & Data Loggers offer a variety of ways to monitor moist room or curing tank temperatures and log the data for a permanent record. Models with remote thermocouple probes, submersible loggers, and units that record in ink on paper charts are all convenient solutions.

- Humidity Meters monitor the relative humidity of moist rooms as a reliable way of backing up visual observations of free moisture on the samples. Available as analog/manual or digital instruments.

Water Curing

Concrete Curing Tanks and other open water storage units make an ideal water curing method for limited numbers of specimens. The simple and low maintenance method meets specification requirements while offering a good alternative to moisture rooms, especially for temporary or field applications. Calcium hydroxide (hydrated lime) must be added to the water to prevent the leaching of minerals from the concrete samples. Additional tanks can be added or removed as needed and even interconnected for greater sample capacity and heating/cooling efficiency.

Photo Credit: aashtoresource.org

Pros:

- Ideal for short-term and limited space applications

- Simple equipment sets up quickly and is inexpensive

- Available in a range of capacities and dimensions

- Sufficient moisture levels are never in question

- Minimal maintenance required (clean and refill tanks every 24 months)

Cons:

- Tanks are not space-efficient for large numbers of samples

- Handling specimens requires waterproof gloves

- Occasional leakage or spillage can occur

- Large water surfaces can tend to humidify rooms

Our Recommendations:

Steel Curing Tanks come in three models with capacities from 100gal (379L) to 300gal (1,136L). Features of the steel units include:

Steel Curing Tanks come in three models with capacities from 100gal (379L) to 300gal (1,136L). Features of the steel units include:- Pipe-reinforced top for extra-strong crush-proof rim

- Sturdy rolled seam with enclosed sealant to prevent leaks

- 22-gauge, zinc-coated galvanized steel with diagonal and horizontal corrugations for strength

- Drain plug for simple maintenance

Plastic Curing Tanks are available in three models with 40gal (151L) to 180gal (681L) capacities featuring:

Plastic Curing Tanks are available in three models with 40gal (151L) to 180gal (681L) capacities featuring:- Heavy seamless construction from recycled materials

- Rust-proof and impact resistant

- Leakproof

- Flexible, with sloped sides to allow partial nesting in storage

Temperature Control and Tracking

Water temperature in curing tanks must be maintained at the same 23.0±2.0°C (73.4±3.5°F) level as in moist rooms and recorded at the same 15-minute intervals. Seasonal fluctuations and stratification of the water can result in tank temperatures straying from the stated requirements. Fortunately, there are some simple solutions to ensure your curing and testing program stays on track.

- Curing Tank Heaters control water temperatures over a limited range in large tanks and are an economical and popular way to ensure specification compliance. These immersion heaters mount direct on tank walls and include a grounded power cord and built-in fuse.

- Heater/Circulators are highly accurate and offer precision temperature control and constant fluid circulation in smaller tanks. Accuracy is up to ±0.09°F (0.05°C).

- Curing Tank Circulators are simple and cost-effective submersible pumps that ensure even temperatures at all points in curing tanks. Operation in the waterproof nylon plastic housing is silent.

- Temperature Recorders & Data Loggers are the same product range recommended for use in moist rooms and a convenient way to monitor concrete curing tank temperatures and log them for a permanent record. Models with remote thermocouple probes, submersible loggers, and units that record in ink on paper charts are all convenient solutions.

- Concrete Reference Thermometers are required to check the accuracy of other temperature devices used in cement and concrete testing laboratories. These glass thermometers meet ASTM E77 and are supplied with a certificate of NIST traceability. Available in models with mercury or non-mercury indicating fluid.

Whatever methods and equipment you prefer, remember that proper curing is essential to optimum strength development in concrete strength specimens. Without it, any results from concrete strength tests are open to question. For expert help with your application, contact the testing experts at Gilson.