What is Permeability of Soil

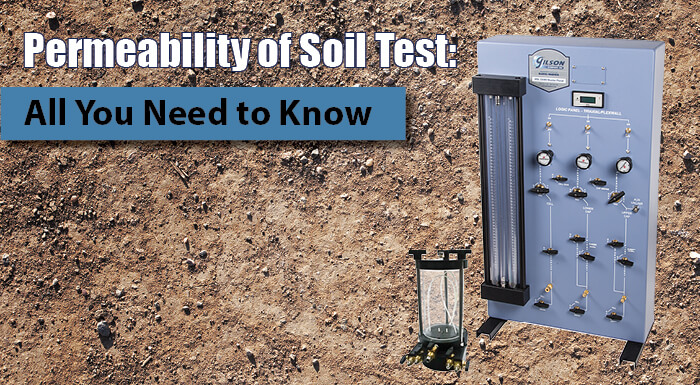

Soil permeability, or hydraulic conductivity, is the rate of the flow of water through soil materials, and it is an essential characteristic across a broad spectrum of engineering and earth science disciplines.

Geotechnical and civil engineers, hydrogeologists, soil, and environmental scientists all use this information for projects such as structural foundations, embankments, earthen dams, flood management, effluent infiltration, and more. It’s no surprise that the porosity and permeability of soils are related.

Factors that Affect Soil Permeability

Soil voids create an easy path for the movement of water, but other factors like hydraulic gradient, soil type, texture, and particle size distribution also affect permeability.

Darcy’s law, which dictates all results from soil permeability tests, is an equation describing the movement of fluids through a porous medium. This equation defines the coefficient of permeability or hydraulic conductivity of soils, a ratio of fluid velocity through the soil matrix to the hydraulic gradient.

Coefficient of Permeability

The coefficient of permeability (K) is the velocity in meters or centimeters per second of water through soils. Fine-grained soils such as clays might have values of around 10-8meters/sec or lower, or a sand and gravel formation could be 10-4meters/sec or higher.

Soil permeability can be estimated using empirical methods like soil survey mapping, soil texture, or particle size distribution. However, a variety of different laboratory and field test methods make it just as easy to measure these properties directly. The soil type and purpose of the test, accuracy required, and specimen type influence the selected test method.

This blog will be your guide in selecting equipment to meet the test method requirements and match the soil type.

How is Soil Permeability Measured

Soil Permeability tests take place under either constant head or falling head conditions:

- Constant Head Test refers to an apparatus where the same relative elevation of the top of the water column (head pressure) remains over the sample throughout the test. It is a valid test for soils with a high rate of flow like sands and gravels, but also some clay soils.

- Falling Head Test allows the head to decrease as water infiltrates the sample, diminishing the pressure over the course of the test. Falling head methods are generally limited to fine-grained soils.

Soil Permeability Testing Equipment

Flexible-Wall Permeability Cells described in ASTM D5084, measure hydraulic conductivity of soils using several methods. The methods within this standard allow several variations on the constant and falling head methods, including tests for the constant rate of flow, and constant volume tests with controlled pressures. The test specimen can be prepared from undisturbed borehole samples (Shelby tubes) or by compacting soils in a mold to a specified density. The sample is encased in a latex membrane and placed inside a fluid-filled, pressurized test cell. A system of valves and burettes mounted on a logic panel permits three-dimensional control of confining pressures on the sample as well as the permeant (typically water) used. The monitoring of sample deformation and volume change takes place throughout the procedure. Although this test is standard and widely specified, it requires considerable sample preparation and can take several days to complete. Karol-Warner manufactures Gilson's complete selection of test cells, control panels, and sample preparation accessories for flexible-wall permeability testing.

Flexible-Wall Permeability Cells described in ASTM D5084, measure hydraulic conductivity of soils using several methods. The methods within this standard allow several variations on the constant and falling head methods, including tests for the constant rate of flow, and constant volume tests with controlled pressures. The test specimen can be prepared from undisturbed borehole samples (Shelby tubes) or by compacting soils in a mold to a specified density. The sample is encased in a latex membrane and placed inside a fluid-filled, pressurized test cell. A system of valves and burettes mounted on a logic panel permits three-dimensional control of confining pressures on the sample as well as the permeant (typically water) used. The monitoring of sample deformation and volume change takes place throughout the procedure. Although this test is standard and widely specified, it requires considerable sample preparation and can take several days to complete. Karol-Warner manufactures Gilson's complete selection of test cells, control panels, and sample preparation accessories for flexible-wall permeability testing. Constant Head Permeameters measure the coefficient of permeability of non-plastic soils with no more than 10% of particles passing a 75µm (No. 200) test sieve. The procedure described in AASHTO T 215 is also a withdrawn standard in ASTM D2434. The test is performed under constant head conditions in a rigid-wall sand and gravel permeameter with a diameter of 8 to 12 times the maximum particle size and equipped with porous stones to prevent sample loss. Two manometer ports connect to a double-tube manometer to measure changes in head pressure during the test. A constant head tank supplies deaired water to the specimen. Permeability tests can be performed with the sample from 0% to 100% relative density, as required. After compacting thin layers of the prepared granular soil sample in the permeameter, a special sliding-weight compaction hammer or vibrating tamper provides a higher relative density if required. The test is initiated after the vacuum saturation of the sample with deaired water. Readings for time, head (water levels in the manometer tubes), and quantity of flow under intervals of increasing head pressures determine final results.

Constant Head Permeameters measure the coefficient of permeability of non-plastic soils with no more than 10% of particles passing a 75µm (No. 200) test sieve. The procedure described in AASHTO T 215 is also a withdrawn standard in ASTM D2434. The test is performed under constant head conditions in a rigid-wall sand and gravel permeameter with a diameter of 8 to 12 times the maximum particle size and equipped with porous stones to prevent sample loss. Two manometer ports connect to a double-tube manometer to measure changes in head pressure during the test. A constant head tank supplies deaired water to the specimen. Permeability tests can be performed with the sample from 0% to 100% relative density, as required. After compacting thin layers of the prepared granular soil sample in the permeameter, a special sliding-weight compaction hammer or vibrating tamper provides a higher relative density if required. The test is initiated after the vacuum saturation of the sample with deaired water. Readings for time, head (water levels in the manometer tubes), and quantity of flow under intervals of increasing head pressures determine final results.- Constant/Falling Head Permeameters allow the option of testing granular soils under either constant head or falling head conditions but do not meet published ASTM or AASHTO test method requirements. They share a similar design with the ASTM/AASHTO granular soil permeameters but have a single port for connection to a single-tube manometer. Test set-up and sample preparation are identical to the ASTM/AASHTO permeameters.

Compaction Permeameters are 4in or 6in (102 or 152mm) soil moisture/density (Proctor) compaction molds supplied with upper and lower plates fitted with valves and ports to function as permeameters. Either constant head or falling head permeability testing can be performed directly on the compacted specimens with no need for extensive preparation. Proctor or California Bearing Ratio (CBR) samples molded using standard compaction methods. Porous stones at either end of the samples provide drainage. There are no specific ASTM/AASHTO test methods for these devices, but they provide useful information in the design process. Permeability testing with compaction permeameters uses conventional equipment and techniques. Double-tube manometers connect to inlet and outflow ports to measure the flow of the deaired water.

Compaction Permeameters are 4in or 6in (102 or 152mm) soil moisture/density (Proctor) compaction molds supplied with upper and lower plates fitted with valves and ports to function as permeameters. Either constant head or falling head permeability testing can be performed directly on the compacted specimens with no need for extensive preparation. Proctor or California Bearing Ratio (CBR) samples molded using standard compaction methods. Porous stones at either end of the samples provide drainage. There are no specific ASTM/AASHTO test methods for these devices, but they provide useful information in the design process. Permeability testing with compaction permeameters uses conventional equipment and techniques. Double-tube manometers connect to inlet and outflow ports to measure the flow of the deaired water. Shelby Tube Permeameters are kits of components to build a permeameter around a section of an undisturbed sample retained in a 3in (76mm) Shelby tube. The specimen does not need to be extruded, ensuring minimal disturbance to silty or sandy materials or bedding structures of sensitive soils. ASTM or AASHTO documents do not cover the test method, but it allows constant or falling head testing on minimally disturbed specimens. A section of the tube is cut to a maximum length of 6in (152mm) using a large pipe cutter, or band saw. End caps have ports for water inflow and egress positioned at each end of the sample for connection to double-tube manometers. Threaded rods secure the permeameter assembly.

Shelby Tube Permeameters are kits of components to build a permeameter around a section of an undisturbed sample retained in a 3in (76mm) Shelby tube. The specimen does not need to be extruded, ensuring minimal disturbance to silty or sandy materials or bedding structures of sensitive soils. ASTM or AASHTO documents do not cover the test method, but it allows constant or falling head testing on minimally disturbed specimens. A section of the tube is cut to a maximum length of 6in (152mm) using a large pipe cutter, or band saw. End caps have ports for water inflow and egress positioned at each end of the sample for connection to double-tube manometers. Threaded rods secure the permeameter assembly. Double-Ring Infiltrometers measure soil infiltration rates in the field for geotechnical and environmental applications such as dam and reservoir design or liquid waste and leaching studies. This constant head test follows ASTM D3385 methods and produces optimum results on uniform fine-grained soils. Two metal rings are positioned concentrically and driven into the ground at the test site. After filling the test rings with water, two Mariotte tube devices maintain the liquid at a constant level. Volume changes observed in the tubes during the test determine the infiltration rate. Although this rate is a measurement of fluid movement through soil, it can only be directly related to the coefficient of permeability or hydraulic conductivity if there is considerable prior knowledge of the hydraulic properties. Still, the information the test provides is valuable, and its use is well-established.

Double-Ring Infiltrometers measure soil infiltration rates in the field for geotechnical and environmental applications such as dam and reservoir design or liquid waste and leaching studies. This constant head test follows ASTM D3385 methods and produces optimum results on uniform fine-grained soils. Two metal rings are positioned concentrically and driven into the ground at the test site. After filling the test rings with water, two Mariotte tube devices maintain the liquid at a constant level. Volume changes observed in the tubes during the test determine the infiltration rate. Although this rate is a measurement of fluid movement through soil, it can only be directly related to the coefficient of permeability or hydraulic conductivity if there is considerable prior knowledge of the hydraulic properties. Still, the information the test provides is valuable, and its use is well-established.

To read more information regarding these products, visit our soil permeability testing equipment page.

What is the Soil Percolation Test?

Percolation (“perc”) tests are a simple type of field test often required by local health departments to select a type of septic system for residential or commercial applications in fine-grained soils.

How is the Perc Test Performed?

The typical procedure is to use a soil auger or post-hole digger to dig a hole approximately 18 to 30in (457 to 762mm) deep, fill it with water, and monitor the time it takes to drain. There are dozens of variations to this method among local regulatory agencies, so it’s not possible to give clear procedures here. Results of perc tests can be influenced by so many factors that they are considered unreliable for most scientific or engineering applications.

We hope this blog has answered your questions on how to select methods and equipment for your soil permeability testing applications. Please contact our experienced technical support team for detailed information.