Asphalt binder is a fundamental and surprisingly complex component in the design of modern asphalt pavement mixes. Of the many properties of bitumen that affect its performance in a modern asphalt paving mixture, two are crucial to the long-term success of pavements, viscosity, and rheology.

Rheology is the scientific study of the flow and deformation behavior of materials. Viscosity is specifically the resistance of a liquid to flow. So, viscosity is a rheological attribute. This blog post will explore binder viscosity tests and rheology tests, their applications, benefits, and testing equipment.

Viscosity of Asphalt Binder: The Basics

Back in the day, viscosity was king of the hill when scrutinizing asphalt binder performance. It has never stopped being important, but with modern modified and Superpave performance-graded binders, we now recognize it to be one of many rheological features that reflect performance.

Viscosity describes the rate that which a material deforms or flows over time. Viscosity tests of asphalt binders measure their flow behavior at the elevated temperatures encountered in production and paving operations. Asphalt acts like a viscous (Newtonian) fluid at these temperatures, and viscosity tests are the best choices for characterization.

The two most common viscosity measurements using glass capillary instruments are absolute viscosity and kinematic viscosity.

- Absolute Viscosity is a simple measure of the resistance to the flow of liquids, expressed as the ratio between applied stress in the liquid and the rate of shear. ASTM D2171 and AASHTO T 202 test methods measure the time it takes to draw a volume of bitumen through a capillary tube under a vacuum.

The test is performed with the sample material at 60°C (140°F), assumed to be the maximum temperature of the pavement surface during the summer season. Flow time in seconds multiplied by the viscometer calibration factor is expressed as the viscosity in Pascal-seconds (Pa-s).

- Kinematic Viscosity is the resistance to the flow of a liquid under gravity and is the ratio of absolute viscosity to density of the binder sample. The ASTM D2170 and AASHTO T 201 test method applies to road oils and liquid asphalts tested at 60°C (140°F), and asphalt cements at 135°C (275°F). The higher temperatures simulate mixing and laydown temperatures of the asphalt mixture.

The flow of liquid through a glass capillary viscometer under head pressure at a controlled temperature is measured. The outflow time in seconds multiplied by the viscometer calibration factor yields the Kinematic viscosity. Results are recorded as square millimeters per second (mm2/s), equivalent to centistokes (cSt).

The test apparatus used for the two tests are similar, as shown in the chart below. Vacuum requirements for the kinematic tests are minimal, needing only slight vacuum pressure to initiate gravity flow.

Apparatus for Asphalt Viscosity Tests

| Absolute Viscosity ASTM D2171/AASHTO T 202 | Kinematic Viscosity ASTM D2170/AASHTO T 201 | |

|---|---|---|

| Capillary Viscometers | Asphalt Institute, Cannon-Manning, or Modified Koppers | Zeitfuchs Cross-Arm, Cannon-Fenske, Lantz-Zeitfuchs, or BS U-Tube modified reverse flow |

| Viscosity Baths | Constant Temperature Viscosity Bath | Constant Temperature Viscosity Bath |

| ASTM E1 Thermometers | 47C/47F (Mercury), S47C/S47F (Non-Mercury), and others permitted. | 47C/47F (Mercury), S47C/S47F (Non-Mercury), or S110C/S110F (Non-Mercury). |

| Vacuum System | Vacuum Pump, Vacuum Regulator, Vacuum Manifold | Vacuum Pump, Vacuum Manifold |

Rotational Viscosity: Efficiency and Accuracy

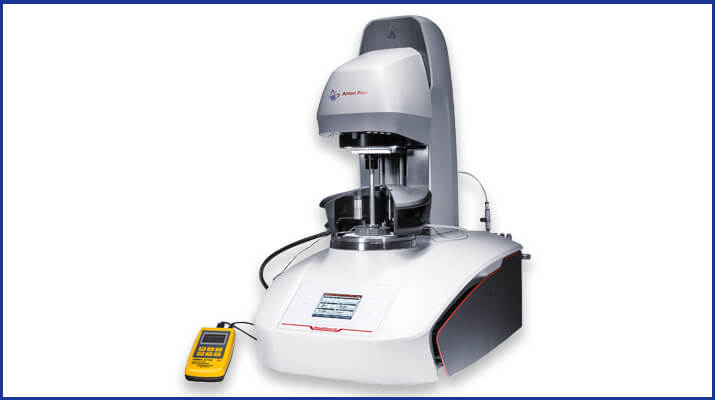

Viscosity testing with traditional glass capillary viscometers is time-consuming, requires training and experience to perform, and is not suitable for all binder types. Rotational viscometers produce repeatable results quickly and correlate closely with glass capillary methods. The standard test methods for the rotational viscometer are published in ASTM D4402 and AASHTO T 316.

Rotational Viscometers measure the torque needed to rotate a selected spindle assembly immersed in the asphalt specimen at a constant speed. Sensors measure the forces, and the software calculates a dynamic viscosity value. Test parameters for speed, temperature, and torque values are precisely regulated, displayed, and recorded in real-time, minimizing operator error and allowing straightforward reporting of results. These instruments test various asphalt binder types at different speeds and temperatures but are most often operated at 135°C (275°F) to test Superpave PG asphalt binders.

Rheology: Longer-Term, Bigger Picture

When the Strategic Highway Research Program (SHRP) program was initiated in 1987, there was a push for improved characterization of asphalt binders that would result in longer-lasting pavements. High-temperature viscosity tests alone are not effective at predicting long-term performance.

Asphalt binders are viscoelastic, viscous at high temperatures but more like an elastic solid at in-service temperature ranges. Binder properties are also affected by short-term aging during production and handling and long-term aging over the life of the pavement. Understanding flow behavior over a wider temperature range and the impact of aging allows more complete predictions of long-term pavement performance.

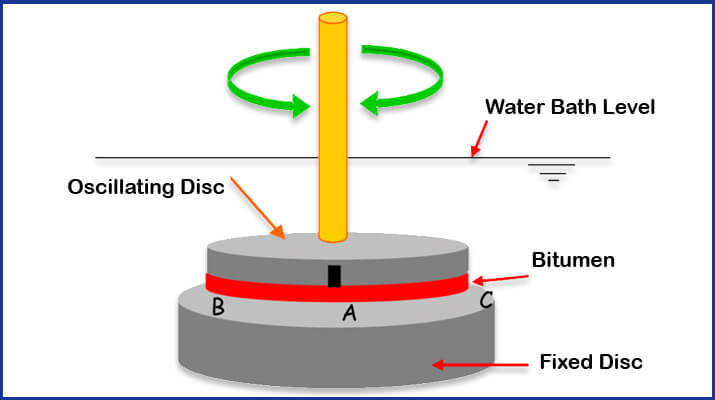

Dynamic Shear Rheometers (DSR) measure the shear modulus and phase angle of both elastic and viscous materials. These instruments were borrowed from the food industry in 1993 to assess asphalt binder rheology over a wide range of conditions and temperatures. Dynamic shear testing is used to classify Superpave PG asphalt binders. DSR testing on binder samples aged in Rolling Thin Film Oven (RTFO) and Pressure Aging Vessel (PAV) devices helps predict tendencies for rutting, stripping, and fatigue cracking in trial mixes before the paving mix is produced.

In the dynamic shear rheometer test, thin 8mm or 25mm circular specimens of the binder are prepared in special molds. 8mm samples are tested between 39°F and 104°F (4°C and 40°C), while the larger 25mm samples are tested at 115°F (46°C) or more. The disc is mounted between the upper and lower plates of the DSR in an environmental chamber and oscillated under pressure as torque is measured and recorded. Speed, pressure, and temperature are controlled by the device’s instrumentation and software, so operator influence is minimal.

We hope this blog post has helped you understand the significance of asphalt binder viscosity and rheology and the testing equipment used to measure these properties. Please contact our testing experts to discuss your specific test application questions.