Construction Materials Testing Laboratory for In-Field Tests

This article examines primary equipment for typical operations performed where field laboratories for construction materials testing are required. With so many possible variations in specific project requirements, this list cannot be all-inclusive. If you have questions about your unique applications, don't hesitate to contact the testing experts at Gilson. They have laboratory and field experience and are ready to help.

If you need guidance on the basic equipment needed for your field testing lab, read our Setting Up A Field Lab for Construction Materials Testing: The Essentials which discusses general lab equipment needed for a construction material testing lab for most applications.

Soils Testing

Temporary labs for earthwork projects tend to focus on testing moisture/density relationships (Proctor), soil density (field compaction) tests, Atterberg limits, and grain size, as measured by sieve and hydrometer tests. Field CBR equipment needed for in-situ strength tests are sometimes performed but do not require a field lab.

Proctor: Selecting equipment for soil moisture/density relationship testing in the field is influenced by the frequency of tests required and the number of people available to perform them. Several test standards use similar methods to determine these values. The most frequently used are ASTM D698 and D1557/AASHTO T 99 and T 180. Read our blog Proctor Compaction Test: A Basic Guide for more information about the test.

- Mechanical soil compactors save time and effort and improve test repeatability. They also have a large footprint, are heavy, and require power to operate.

- Proctor hammers are inexpensive and acceptable in the test methods but are physically demanding to operate, especially the versions for modified Proctors.

- Proctor molds in solid or split-mold versions are available for standard or modified methods. Split sample molds allow easy extraction of compacted samples without the need for a soil sample ejector.

- Straightedges are required and used to strike off the compacted samples.

- A Laboratory mixer is not strictly required in the standard test methods, but makes sample preparation and mixing much more efficient.

Atterberg Limits: The plasticity index is one of the most common tests to characterize soil types, defining its transition between solid, plastic, and liquid states. ASTM D4318 lists test methods for both liquid and plastic limits. For AASHTO, the liquid limit test is T 89, and the plastic limit is T 90. For more information read our blog Atterberg Limits: A Quick Reference Guide.

- Liquid limit machines in motorized or manually cranked models are rugged devices that stand up to repeated field use.

- Plastic limit rollers enhance the accuracy and repeatability of Atterberg limits testing.

- Liquid Limit / Plastic Limit test accessory sets contain the accessories required to perform liquid and plastic limit tests.

- Soil Grinder, the test method does not require one, but these compact benchtop units are much faster than manual methods when preparing Atterberg limits samples.

Grain Size: A complete particle size analysis of soils with both fine and coarse-grained fractions currently requires two different test standards. ASTM D6913 is a sieve analysis of material down to 75µm (#200), and D7928 (supersedes withdrawn standard D422) is a test method for hydrometer analysis of soils between 75µm and 0.2µm. A draft standard combining these two methods is currently in development by ASTM subcommittees. The AASHTO version for this standard is T 88.

- Test Sieves with 8in or 12in frames depending on expected sample volumes and particle sizes. You can nest test sieves for storage, but it’s crucial to protect the wire cloth from damage.

- Sieve Shakers require space and electrical power but decisively eliminate the variables that affect the accuracy of manual sieving—select models based on test sieve sizes, efficiency, noise suppression, or dust control.

- Screen Shakers are a must for effective gradations of large samples with particle sizes from 4.75mm to 100mm (No. 4 to 4in) or more. Their weight and aggressive mechanical action make sturdy floors necessary if used in temporary structures.

- Hydrometer analysis is a sedimentation test that measures the particle sizes of fine-grained soils.

Concrete Testing

Most of the efforts in concrete field laboratories center on curing of samples and on-site strength testing. Tests for compressive strength use concrete cylinders, and flexural strength testing uses concrete beams. The equipment list is short, but outfitting can still be a challenge. Sample curing tanks can take up considerable floor space, and concrete compression testing machines are heavy and difficult to handle.

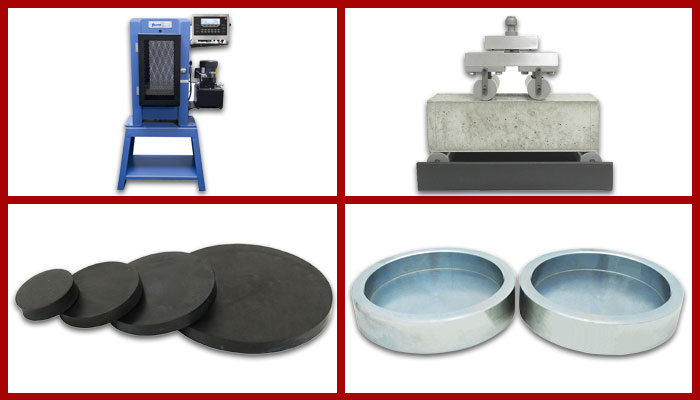

Strength Testing: One machine equipped with accessories is all that is needed to carry out tests on both compressive and flexural strength samples.

- Compression testing machine loads should typically be about 80% of their maximum capacity to avoid elongation of the frame and shortened service life. A 250,000lbf (1,112kN) capacity machine can test 6x12in cylinders up to 7,000psi (48.3mPa), but if 4x8in cylinders are used, strengths can range up to 15,900psi (109.6mPa). If 4x8in cylinders are permitted, we recommend a lighter 250,000 testing machine. A 300,000lbf capacity machine will test 6x12in concrete cylinders up to 8,500psi (58.6mPa). ASTM C39 and AASHTO T 22 are the most widely used standard test methods. For help read our Guide to Selecting The Right Concrete Compression Machine.

- Flexural testing accessories quickly attach to compression machines for testing of 4x4in or 6x6in flexural beam samples up to 30in (762mm) in length with center-point or third-point loading ASTM C293 or C78, and AASHTO T 177 or T 97.

- Neoprene pads are the best choice for concrete cylinder testing in field labs. The caps are compact, long-lasting, convenient, and don’t require the storage, heating, and handling of sulfur mortar. The pads also comply with the latest version of ASTM C1231. Each cylinder diameter requires only one set of two steel retaining rings.

Curing: Water tanks for curing concrete strength samples are much more workable in a remote setting than moist curing rooms or chambers. The tanks meet all the requirements of ASTM C511 to control curing conditions. Be sure to saturate the curing water with calcium hydroxide (high-calcium hydrated lime). Plain tap water can leach lime out of concrete samples and reduce their strength. For an in-depth look at creating the ideal curing system read our blog Concrete Curing: What Equipment is Right for You?.

- Curing tanks with metal or plastic construction come in a variety of sizes for convenient layout in limited floor space. Seamless plastic tanks are lightweight, durable, and rustproof.

- Curing tank heaters are easy to mount in tanks and maintain required curing conditions in ambient temperatures as low as 53°F (12°C).

- Curing tank circulators maintain even temperatures in curing tanks, ensuring stable strength development in samples.

Asphalt Testing

Typical asphalt satellite laboratories must perform more tests than other types of construction field labs. With asphalt mixes, there are more test methods required, and the demands for rapid feedback of quality control values during lay-down operations require more testing equipment on-site. Refer to our previous blog Setting Up a CMT Field Lab: the Essentials for general lab equipment like sieves, sieve shakers, ovens, etc. Here we will discuss items specifically for asphalt testing.

Sampling and dividing: Bulk samples taken directly from the paving mat as cores or in uncompacted bulk form are quickly returned to the field lab and prepared for testing.

- Quartermaster sample divider safely split uncompacted hot asphalt mix samples down to testing-size specimens.

- Bucket liner sample bags reduce handling and streamline separation and storage of samples.

Asphalt binder content: Extraction of binder falls into either solvent-based or burn-off methods. Solvent methods are less costly initially but require consumables like filters and solvents that may become hazardous materials once used. Tests can also take longer to complete. Asphalt furnaces provide quick and accurate results with simple operation and few consumables but have a higher initial cost. The furnaces are larger and heavier and usually require hookups by an electrician. For a comparison between solvent and ignition be sure and read our blog Asphalt Content Testing: Solvent Extraction vs Ignition Furnace.

- Asphalt extraction test equipment consists of a centrifuge, vacuum, or reflux models that use extraction solvents and filters to strip out asphalt binder. Popular centrifuge models are self-contained and provide faster test results. All models comply with ASTM D2172 and AASHTO T 164.

- Asphalt content furnaces burn away binder from asphalt samples, completing tests in as little as 30 to 45 minutes. They require electrical supplies of 208 to 240 volts and draw a current of 20 to 45 amps. The furnaces meet ASTM D6307 and AASHTO T 308 standards.

Specific gravity: The ASTM D2041/ AASHTO T 209 “Rice test” for asphalt mixtures is a fundamental test in any asphalt lab. The standard test methods list several options for the equipment required. The list below consists of Gilson’s recommendations. Read our Specific Gravity of Asphalt blog for more in-depth information.

- Aluminum Pycnometers with 2,000g or 4,000g sample capacity each include a metal lid and an acrylic lid with fixtures and hoses for vacuum supply. Also included are a metal water aspirator and tubing.

- Oilless vacuum pump for low maintenance and is more convenient than a water aspirator as a vacuum source. or aspirator with vacuum gauge.

- Digital residual pressure manometer monitors vacuum pressure during the deairing phase of the test. Models are available in standard or NIST certified versions.

- Rice test shaker mechanically agitates several types of asphalt pycnometers during deairing.

- Specific gravity benches position the water tank, balance, and suspended pycnometer correctly for convenient weighing of Rice test samples.

- Water bath tanks, fitted with a tank heater/circulator, ensure the correct water temperature for suspended weighing of specific gravity pycnometers.

- Weighing cradles have stiff, heavy-wire construction for suspension weighing of material samples and specific gravity pycnometers. The cradles attach by wire to the weigh-below fixtures on a variety of scales and balances.

Specimen Compaction: Project specifications dictate whether pavement designs use Marshall or Superpave criteria. Each system uses a different method to mold cylindrical specimens for testing.

- Marshall Design Method, ASTM D5581, D6926; AASHTO R 68, T 245 for an in-depth look at this method read our blog The Marshall Test: Everything You Need to Know.

- Marshall compactors in manual or automatic models compact asphalt materials into 4in or 6in (102mm or 152mm) diameter molds.

- Marshall compaction molds form test specimens for strength and specific gravity testing.

- Marshall stability testers measure the stability and flow of the compacted Marshall specimens under compression.

- Data acquisition software automatically calculates the load and displacement values with real-time graphs and reports test data.

- Superpave Design Method, ASTM D6925; AASHTO T 312. Read our blog What is Superpave? Understanding Performance-Based Asphalt for a comparison between the two methods.

- Superpave gyratory compactors produce compacted asphalt specimens suitable for further testing of volumetric and physical properties and determine the relative density of the sample.

- Water Baths condition compacted Marshall or Gyratory specimens in the water at ±1% of temperature setpoint.

Aggregate Testing

Field laboratories set up to test construction aggregates nearly always perform gradation (particle size) analysis and moisture content determinations. Other types of tests are not as prevalent, but angularity, flat/elongated particles, and specific gravity determinations are common.

Particle sizing: ASTM C136 (AASHTO T 27) and ASTM C702 are by far the most common and primary test methods performed that has more influence on the performance of hardened concrete, asphalt, and base material performance than any other characteristic of aggregates.

- ASTM test sieves can be purchased in various frame diameter or material, and available in a wide array of opening sizes. Sieve shakers come highly recommended for repeatable and efficient test processing of aggregate samples. Depending on the test they are available in a variety of agitation options.

- Sample splitters allow a representative sample to be separated from a bulk quantity without changing its properties. Using the proper splitter can significantly reduce variability in the lab.

Angularity and shape: The texture and shape of aggregate particles affect the performance and characteristics of concrete and asphalt mixes.

- Aggregate angularity apparatus determines the uncompacted void content of fine and coarse aggregates. Fine aggregates are tested following test methods in ASTM C1252 and AASHTO T 304. AASHTO T 326 spells out the methods for testing coarse aggregates.

- Proportional caliper devices determine flat and elongated dimensions to meet ASTM D4791 standards.

- Flakiness and Elongation Indexes use the size and length gauges specified in BS EN 933-3:2012, a British and European standard.

We hope this two-part series on outfitting a temporary field-testing facility has helped you make some decisions for your project. Please contact us today if you have any questions.