Specific Gravity of Asphalt

Several AASHTO and ASTM standards govern the measurement of the specific gravity of asphalt, also known as theoretical maximum specific gravity, or simply the Rice Test. Test methods AASHTO T 209 and ASTM D2041 determine theoretical maximum specific gravity and density values used to calculate air voids in the compacted mix and establish targets for compaction during laydown.

Percent Air Voids in Asphalt

The test results also allow the calculation of bitumen absorption by mineral aggregates. If the percentage of air voids is too low, rutting and shoving of the pavement can happen. If the percentage of air voids is too high, the pavement can be subject to moisture damage, exhibit decreased strength, and have a shorter fatigue life when compared to pavements with correct air void percentages.

These standards define density as “the mass of a cubic meter of the material at 25°C (77°F) in SI units,” and specific gravity as “the ratio of a given mass of material at 25°C (77°F) to the mass of an equal volume of water at the same temperature.” Many state DOTs also have state-specific test procedures, in addition to the ASTM and AASHTO standards. This blog post will explore the basics of what to know about the specific gravity of asphalt, what equipment is needed, and how it gets the job done with the Rice Test.

What is the Asphalt Rice Test?

The Asphalt Rice Test is a routine test performed by asphalt producers, state departments of transportation, and testing labs. Reliable results from this test method depend on competent personnel, and the selection of quality equipment can have a direct impact on test results. Choosing equipment that minimizes human input variables will increase the accuracy and repeatability of this test, as well as increase lab efficiency.

How Does the Asphalt Rice Test Work?

The Rice Test compares the mass of the sample to its volume, excluding the air voids, by measuring the dry mass of the loose HMA sample either at the beginning of the test or at the end of the test, after it has been dried. The volume is calculated by dividing the mass of the water displaced by the sample by the unit weight of water.

An asphalt sample is prepared by heating it to a constant 135°C and separating it into loose particles by hand. The sample is placed into a calibrated pycnometer and weighed, then water at 25°C (77°F) is added to cover the sample. A cover is placed on the pycnometer, and a vacuum is applied.

To obtain mass and volume, it is necessary to remove free and entrapped air from the asphalt sample immersed in water in the pycnometer. A vacuum pump quickly removes the free air, but mechanical agitation under vacuum by a Rice Shaker is required to completely remove entrapped air from the mixture. A final weight to determine volume is taken by suspending the pycnometer with a sample in water or by completely filling the pycnometer with water.

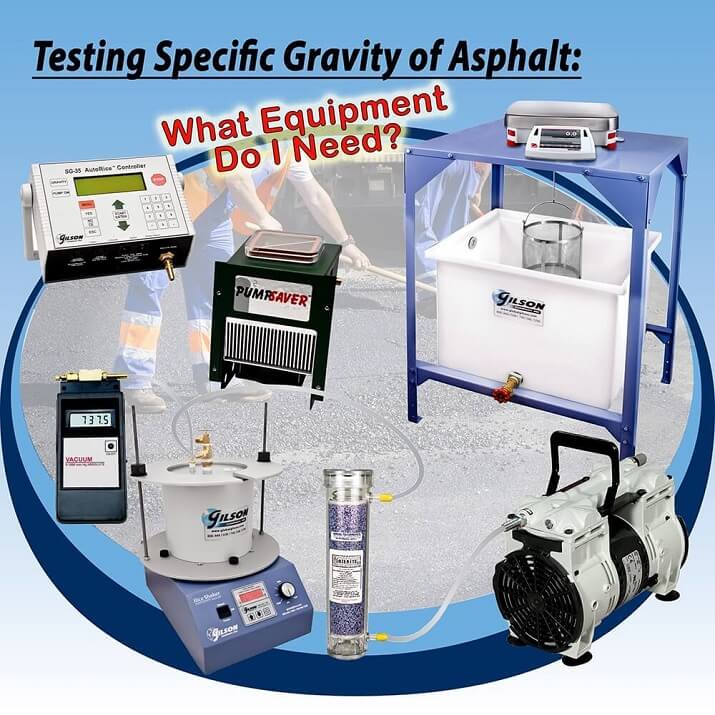

What Equipment is Needed and What Does It Do?

There are different products available to get the job done in accordance with ASTM, AASHTO, and any applicable state DOT standards. Some will be more time and labor-intensive, but more economical, while those that are automated can be significantly more time and labor efficient.

To get started, a mechanical agitation device is required by AASHTO T 209 and ASTM D2041, and the Rice Shaker for Specific Gravity & Asphalt Rice Test provides consistent and automatic agitation. Two different set-up scenarios for using the Rice Shaker are shown below: the basic Asphalt Rice Test setup, which is more time-consuming and requires manual interaction from the operator, and the automated set-up using the AutoRice™ Digital Manometer/Controller System with PumpSaver™ Air-Drier that reduces operator and test time and delivers results directly to the computer.

- Basic Equipment for the Asphalt Rice Test … In a typical set-up, the vacuum pump removes free air, while the Rice Shaker agitates the pycnometer to remove entrapped air. The Digital Residual Pressure Manometer measures the vacuum applied to the sample from the vacuum pump, and the Drierite Air/Gas Dryer with Drierite absorptive granules prevents water from entering the vacuum pump.

- Equipment for the Asphalt Rice Test with AutoRice™ Controller System … The new AutoRice™ Digital Manometer/Controller System allows precise control of vacuum pressure and time and can be equipped to monitor the vibration energy of the Rice Shaker or other mechanical agitators. Accuracy and repeatability are increased while decreasing the need for constant attention to the procedure. The PumpSaver™ air drier protects the vacuum pump from moisture and optimizes efficiency.

In addition to the agitation device and other basic tools used with this test, such as a vacuum container, thermometer, vacuum gauge, and bleeder valve, there are other products used with both set-up options, and some are highlighted below.

- A Pycnometer or Filter Flask, which meets ASTM and AASHTO standards, is required for specific gravity determinations. Note that a Flask Adapter or Pycnometer Adapter set for the Rice Tester may also be required depending upon the model used. A thick-walled Glass Vacuum Flask can be used for weighing in the air only.

- Either a vacuum pump or water aspirator is needed to effectively evacuate air from the container to a residual pressure of 4.0kPa (30mm of Hg) or less. If using an Oilless or High Vacuum Pump with Gauge, a trap must be installed to reduce the amount of water vapor that gets into the pump

- The standards require an Absolute Pressure Manometer or calibrated absolute pressure gauge to confirm that the specified pressure is applied, and the device must be able to measure residual pressure to 4.0kPA or less. A Mercury Manometer can be used in the Asphalt Rice Test; however, local regulations should be checked before using any mercury device. The Digital Absolute Pressure Manometer is mercury-free and environmentally friendly; both manometers perform in compliance with the test standards.

- The Specific Gravity Water Tank is used for suspended weighing, and, together with a Curing Tank Heater/Circulator, maintains the required constant temperature of 25°C + 1°C (77°F + 2°F). The Specific Gravity (relative density) Bench offers convenience in this process, with the easy weighing of samples suspended in water. It holds the water tank, weighing cradle, balance, heater, and circulator.

- A Balance that can be read to the nearest 0.1g, with a minimum 10kg capacity. A weigh-below hook is needed, as well as a Weighing Cradle when suspension weighing is performed.

When testing is complete, theoretical maximum specific gravity (gmm) is determined from the following:

- Mass of the dry sample in air

- Mass of container underwater

- Mass of container with sample underwater

For more specific details on testing for theoretical maximum or asphalt specific gravity and density, refer directly to the ASTM D2041 or AASHTO T 209 test standards. You can also learn more about the SGA-5R Rice Shaker for Specific Gravity & Asphalt Rice Test by viewing our video below.

Gilson Is Here to Help

Contact our testing experts for more information or to discuss your testing application.

Testing Resources

Standard Test Methods, Specifications, and Practices

Individual test methods and specifications referenced in our product descriptions, blog articles, and videos are available for review or purchase from the professional organizations noted.

- ASTM International (American Society for Testing and Materials)

- AASHTO (American Association of State Highway and Transportation Officials)

- ACI (American Concrete Institute)

- State DOTs (Departments of Transportation)

- ISO (International Organization for Standardization)

- BS (British Standards)

- EN (European Standards)