- Log in

- Favorites List

-

Shopping Cart

You have no items in your shopping cart.

- Gilson Chat

Schmidt Hammers

Schmidt Concrete Test Hammers by Proceq are the original brand of rebound hammers for non-destructive testing of hardened concrete by the rebound method. Schmidt Hammers are sometimes referred to as Swiss hammers. Gilson's line of Schmidt Hammer models meets ASTM, British, and European standards.

A plunger rod is pressed against the concrete surface until a spring-loaded mass releases, causing an impact. The degree that the mass bounces back is registered as the "rebound number" and used to evaluate the hardness properties of the concrete. Simple operation and portability make the concrete test hammer a good choice for rapid assessments of hardened concrete.

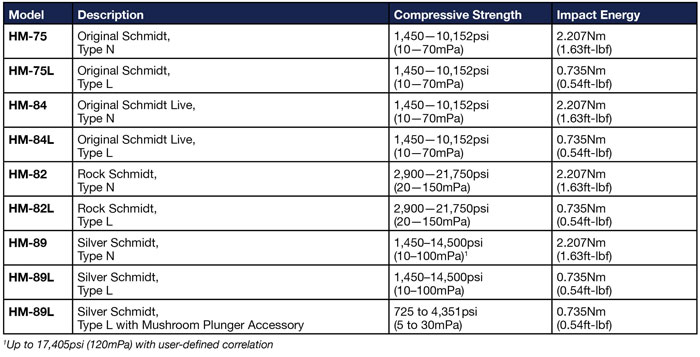

Click the table above to enlarge, print, or download

There are two types of concrete rebound test hammers based on the impact energy they produce. Both types are effective on concrete mixes with a similar range of compressive strengths.

Schmidt concrete hammers are available in various model types, including the Original Schmidt Hammer, Silver Schmidt, Schmidt Live, and Rock Rebound Test Hammers. Models are available in simple analog versions or with electronic measurement systems and data management features. All include a carrying case, carborundum stone, reference chart, and certificate of conformity. Calibration Anvils are available and purchased separately.

Type N, Schmidt Test Hammers have a higher energy output of 1.63ft-lbf (2.207Nm) to test a wide range of concrete structures. They are often considered as “standard” models and used when testing concrete elements 4in (100mm) or more in thickness.

Type L, Schmidt Test Hammers test concrete with similar compressive strength ranges but generate lower impact energy of 0.735Nm (0.54ft-lbf). They are ideal for providing more repeatable values when testing green concrete or areas less than 4in (100mm) thick. They are ideal for precast pipe or checking early-age concrete for form removal or post-tensioning operations. Type L hammers also reduce cosmetic and structural damage to concrete with thin cross-sections.

- Original Schmidt is the traditional Type N and Type L analog models produced by the original manufacturer and has been a trusted solution since the 1950s. Quality materials, rugged design, and meticulous craftsmanship make these models stand out from the competition. The Type L model meets ASTM D5873 for the assessment of rock hardness.

- Original Schmidt Live is available in Type N and Type L models. Both use a traditional impact mechanism with a steel plunger. The R-value measurements are captured with an accelerometer and electronically processed to make strength and uniformity assessment more accurate, repeatable, and efficient.

The digital Schmidt Live system features cloud-based connectivity for instant job site reporting of test results in PDF or CSV file formats. Lag values, number of impacts, impact angle correction, and series identification are automatically recorded and calculated.

- Silver Schmidt uses precision optical encoders to measure the impact and rebound energy of the lightweight aerospace alloy impact plunger. This system is available in Type N and Type L models. They feature automatic position correction and are unaffected by internal friction, maximizing accuracy and repeatability over traditional systems. Rebound numbers are expressed as Q values, better suited for testing high-strength concretes.

The Silver Schmidt meets ASTM and international standards and is optimized for use with pulse velocity instruments in sonic rebound (SONREB) methods for improved compressive strength estimates.

- Rock Schmidt are available in Type N or Type L models, designed especially for geological and geotechnical applications to classify hardness and strength characteristics of natural rock formations. They meet ASTM D5873 to assess suitability for construction purposes, predict penetration rates for boring machines, and estimate the rate of hydraulic erosion loss. Rebound values assess age and weathering or estimate excavation or tunnel boring penetration rates.

They feature intuitive menu-guided operation, electronic data processing, automatic correction for testing positions, and test data storage.

For more information on Schmidt Hammers, here are our related blogs: