- Log in

- Favorites List

-

Shopping Cart

You have no items in your shopping cart.

- Gilson Chat

Materials Testing EquipmentContact Us Today! 800-444-1508

Search

Marshall Testing Equipment

The Marshall Test is a popular and proven method to measure the load and flow rate of asphalt specimens, beginning with compaction into molds using manual or automated Marshall Compactors, and conditioned in a Water Bath at the specified temperature.

Flow values are determined with specimens in a Marshall Breaking Head for loading in our quality Marshall Stability Load Frames. Gilson supplies every necessary component for advanced Marshall testing.

- Marshall Stability Systems are highly customizable Load Frames outfitted with a wide selection of analog or digital components for measuring, displaying, and recording the load and flow of asphalt specimens.

- Marshall Compactors are used to compact asphalt into molds to prepare specimens for Marshall testing.

- Marshall Compaction Mold Sets & Components are molds, bases, or collars sold individually to expedite sample processing or to replace existing equipment.

- Circular Paper Discs are made of heavy, tear-resistant paper to prevent material from sticking to the Compactor or Hammer surfaces.

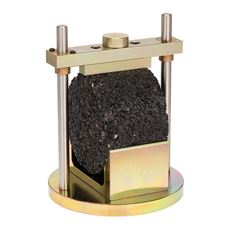

- Sample Ejectors quickly extrude compacted soil or asphalt samples from soil density or Marshall compaction molds.

- Budget Sample Ejector is used for specimen extraction using the loading mechanism of a load frame.

- Water Baths use heated water to condition Marshall Stability specimens prior to loading.

- Conditioning Chamber holds samples for IDEAL-CT, SCB, I-FIT, or other tests at precise, PID-controlled temperatures

- Indirect Tensile Loading Fixtures determine Lottman or Indirect Tensile values of asphalt mixes and are supplied with a base and top for use in Marshall Stability Load Frames.

- Marshall Breaking Heads have upper and lower segments to fit asphalt specimens for loading in Marshall Stability Load Frames.

- Semi-Circular Bend Test Fixture determines the toughness and low-temperature fracture energy of asphalt mixtures.

- Ideal-RT Test Fixture is used for determining resistance to rutting (rutting tolerance) at high temperatures of asphalt mixture.

- Asphalt Tack Coat/Interlayer Shear Strength Apparatus measures the shear strength of the tack coat material between two asphalt layers.

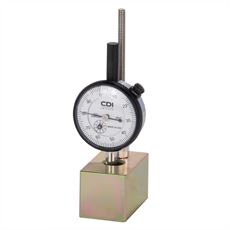

- Dial Flow Meters manually measure flow in Marshall Load Frame assemblies.

For more information on Marshall Testing Equipment, here are our related blogs: