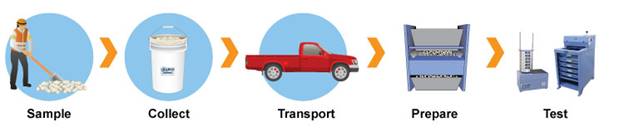

Aggregates play an important role in nearly all phases of highway construction. Quality assurance begins as samples are collected from the job site, prepared, and tested in the lab. This three-part series will cover sieve analysis of coarse aggregate, beginning from gathering samples at a job site, to preparing the samples and testing them in the lab. In Part 1, we’ll highlight tips for proper collection as well as necessary equipment.

Sampling is equally as important as testing in ensuring high-quality, specified aggregates are being used. A sample is merely a small fraction of the total material so it’s important that the sample is truly representative. A representative sample should be obtained in accordance with ASTM D75 and can be obtained from many different sources including:

- Stockpiles

- Conveyor Belts

- Bins or Belt Discharge

- Roadway (Bases and Subbases)

Procedure Overview

Stockpile- Obtaining unbiased samples from stockpiles is notoriously difficult, but it can be done with care and attention to detail. A bucket loader makes the process easier and assures a more representative sample. The loader can quickly extract material from a number of locations and elevations in the pile then combine and mix the portions in a smaller pile for direct sampling. If you need to sample a stockpile manually, start at the top and take at least three increments from the top, middle, and bottom of the pile. Pushing a board into the uphill side of the sampling point prevents additional material from falling into the sampling area. Remove and discard the upper layer and collect the increments from the underlying material with a shovel or scoop. D75 also allows the use of sampling tubes to sample a stockpile at random locations. Carefully collect the entire contents of each shovel or scoop full into an appropriate container.

Conveyor Belts-Conveyor belts are often considered the best source for representative sampling during aggregate production. The process involves collecting three equal and random increments and stopping the belt for each increment. A template is placed on the belt at each end of the sampling location and all of the material for the increment is collected. Fines and dust are recovered from the belt using a brush and dustpan.

Bins or Belt Discharge-Three equal increments are collected from the discharge stream at random intervals and combined into one sample. A pan, bin, or even a loader bucket is passed through the entire stream to collect each increment, insuring a complete cross-section of the material is obtained.

Roadway (Bases and Subbases)-A minimum of three increments are taken from the specified area of the roadway. A random sampling process such as that outlined in ASTM D3665 should be used to ensure sampling locations are distributed properly. A template placed over the selected locations will help in securing increment volumes that are approximately equal. Each increment should consist of the entire depth of material, while carefully excluding underlying material.

Recommended Equipment

A basic, serviceable field kit includes the following:

- Heavy cotton duck or canvas Sample Bags with enough capacity for the required sample sizes. Larger samples of coarser materials may require more than one bag for a complete bulk sample. Limiting weights of individual bags to 50lb (23kg) or less will aid in handling during processing.

- A 5 or 6-gallon bucket or pail with a sturdy handle is a big help when methods call for compiling a sample from a number of locations. Simply lining the bucket with the canvas bag makes sample collection easier by positioning the bag so that it stays open.

- Sample ID Tags of embossable aluminum or moisture-resistant card stock. Data should be marked on the tag or recorded in waterproof ink. One tag should be attached directly to the bag and a duplicate placed inside.

- Loop Wire Ties and a Wire Tie Twister secure bags shut and prevent sample loss during shipping and transport.

- Depending on conditions and material, a square-point or round point shovel for digging and collecting materials. You may also wish to use a scoop. A brush and dustpan for collecting fines is useful, especially with finer materials.

- Sampling probes are an acceptable sampling method, but their use is mostly limited to finer materials to push into a stockpile for optimized sample collection.

- The sampling board helps to manage segregation and prevent stray materials from coming into the sampling zone on stockpiles.

- At a minimum, safety equipment should include the following:

- Safety glasses

- Hard hat

- Steel-toe boots

Sampling Tips

- Always contact a plant representative to accompany you to the sampling site to reduce liability and eliminate misrepresentation of products.

- When sampling from a belt, don’t approach the conveyor machinery until it is completely stopped and you have been given permission to obtain your sample.

- When sampling from stockpiles, using power equipment minimizes sample bias, reduces effort, and is generally safer and more efficient. Advance arrangements should be made to secure the equipment for the time you are on site.

- If power equipment isn’t available, sample stockpiles in increments from the top-third, mid-point, and bottom third.

- Use a board pushed vertically into the pile above the sampling point to minimize segregation.

- Shovel or scoop materials into buckets lined with sample bags for faster and easier handling. Use loop wire ties to prevent loss or sample contamination.

- Use proper labeling procedures including ID, date, location, type, name, and weather conditions.

Please see our aggregate testing equipment for our complete list of aggregate products.