What is the Consolidation Test of Soil?

Karl von Terzaghi is considered by many to be the father of modern soil mechanics. He defined soil consolidation as, "Any process which involves a decrease in water content of saturated soil without replacement of water by air".

When loads are first placed on saturated soils, the water in the pores of the soil matrix carries the pressure without a change in volume. Water is then forced away by higher pore pressure, and the soil solids take up the load as the soil compresses. The unit volume of the soil and the moisture content is reduced. Pioneers in the field of soil mechanics testing recognized early on that this predictable behavior would allow them to calculate the rate and amount of consolidation for a given load and introduced an important consideration into the design of earthworks and structural foundations.

By the time Terzaghi began his research on the subject in 1919 in Istanbul, a loading device to measure the one-dimensional deformation of soil samples was already in use. The oedometer was developed around 1910 by French civil engineer Jean Frontard to measure the characteristics of soils in slope failures of earthen dams. The basic concept of his simple and economic dead-weight loading frame is still in use today. More modern pneumatically-loaded frames that electronically measure and record test data have evolved and operated on these same principles of incremental loads applied under controlled drainage conditions. These innovative, compact pneumatic designs are on the leading edge of accurate, repeatable, and efficient consolidation testing of soils.

In this blog, we will highlight the range of equipment available to perform this fundamental method.

ASTM test method D2435, and its AASHTO equivalent T 216, are the most common one-dimensional soil consolidation tests carried out today. Soil samples mounted in specialized testing fixtures called consolidometers are positioned in consolidation load frames for incremental loading, and the deformation of the soil sample is measured by analog or digital instruments. When consolidation is complete, the sample is unloaded and allowed to swell.

Load Frames

Consolidation Machines provide a platform and loading mechanism for soil consolidometers. To completely characterize the consolidation properties of a soil specimen, the system must apply and stabilize the specified axial load increments very quickly, but without impact, and maintain those loads to ±0.5% for long periods of time. Two categories of load frames are available:

- Dead-weight consolidation load frames provide accurate axial loads to the soil sample through a system of hanging weights suspended from a mechanical lever arm. Weight hangers can be adjusted for 9:1, 10:1, or 11:1 beam ratios for a wide selection of applied loads. A threaded lever support screw allows instant, shock-free application of weight increments. Sample deflection can be monitored with simple analog dial indicators, but data can also be electronically measured and logged by upgrading to digital dial indicators or linear variable displacement transducers (LVDTs). These hands-on loading devices are economical and meet test method specifications, but take up quite a bit of space and are sensitive to disturbances. An experienced operator with a practiced technique for careful placement of weights will produce more repeatable results.

- Pneumatic consolidation load frames use compressed air controlled with precision pressure transducers and regulators to apply and maintain the entire range of consolidation test loads. Models with 16, 32, or 64tsf load capacities test a variety of soil types. As with the dead-weight frames, pneumatic models can be fitted with analog or digital dial gauges, or with LVDTs, providing many options for data collection and calculation. These systems have greater overall accuracy than units using free weights; loads are applied instantaneously and accurately maintained regardless of sample compression. The ease of operation and increased efficiency also mean less operator error, reduced training time, and easier setup. The design is less sensitive to bumps and vibrations, and the compact size takes up less space.

Consolidometers

Consolidometers are testing fixtures in a variety of diameters from about 2 to 4in (50 to 100mm) diameter and 1in (25mm) height that holds a soil specimen ring between two porous stones for consolidation testing. Specimens are precisely fitted into the sample ring of the consolidometer by careful trimming. The ring is often made with a cutting edge on one side to make the trimming process easier. The prepared fixture is then ready to be mounted on the consolidation load frame for testing. Most load frames feature an open loading platform that will accept consolidometers from different manufacturers. The two types of consolidometers have different features to consider:

- Fixed ring consolidometers have the sample ring fixed in place so the sample is loaded only from the top. Higher friction occurs between the ring and sample with this version, but suitable for a wider range of soil types, including softer soils.

- Floating ring consolidometers have sample rings that are not fixed during use but are supported by the friction of the specimen. Loading on the sample takes place from both the top and bottom, so compression occurs toward the middle. Since the weight of the ring cannot be supported by very soft soils, this model is only suitable for stiffer soils.

Measuring Load and Deformation

For dead-weight load frames, determining the sample load is a matter of knowing the mass of the free weight(s), the loading ratio of the beam, and the surface area of the sample. Managing finer adjustments can take time and requires manual manipulation of the weights. For pneumatic machines, the regulator control is adjusted until the total pressure on the digital display divided by the sample surface area equals the desired sample load. Fine adjustments are easier to make with the pneumatic devices. Any loading system should be calibrated at least annually using a metal calibration disc, following the procedure noted in the standard test method. The calibration results account for deflection inherent in the loading frame, filter paper, and consolidometer apparatus under load.

As noted above, monitoring deformation values for either type of consolidation frame can be performed in a number of ways:

- Mechanical dial indicators are simple, inexpensive, and provide all the information needed, but they require a human being to monitor, read, and record the values. Upon completion of the test, the data must be manually calculated and graphed. This can be an economical method when only a few tests are performed occasionally.

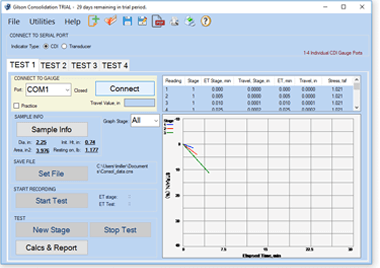

- Digital dial indicators are available that are easier to set up and monitor. They can be used in the same manner as analog dial gauges but can be configured with optional cables and export software to transfer data to an Excel-type spreadsheet or to dedicated software applications.

- LVDTs have a higher level of accuracy and reliability and enable the user to build a data collection system to populate a spreadsheet or export information to software applications.

- Data Acquisition Software collects, displays, and graphs digital test data in real time and creates detailed test reports based on ASTM/AASHTO requirements ready for distribution. These applications ensure efficiency, consistency, and accuracy throughout the consolidation testing process.

We hope this blog has provided some insight to help you select equipment for soil consolidation testing. If you have questions about equipment or applications, please contact us.